Rising Demand from Automotive Sector

The automotive sector is a significant contributor to the CNC Polishing Machines Market, driven by the need for high-quality finishes on vehicle components. As manufacturers strive for excellence in aesthetics and functionality, the demand for CNC polishing machines has escalated. Recent statistics indicate that the automotive industry accounts for approximately 40% of the total market share in CNC polishing. This demand is fueled by the increasing production of electric vehicles, which require specialized polishing for battery components and other intricate parts. Consequently, the CNC Polishing Machines Market is likely to see sustained growth as automotive manufacturers invest in advanced polishing technologies.

Expansion of Electronics Manufacturing

The electronics manufacturing sector is increasingly relying on CNC polishing machines to achieve the desired surface finishes on components such as circuit boards and casings. The CNC Polishing Machines Market is likely to expand as the demand for consumer electronics continues to rise. With The CNC Polishing Machines Market projected to reach over 2 trillion dollars by 2026, the need for efficient polishing solutions is becoming more pronounced. Manufacturers are seeking machines that can deliver consistent quality while minimizing production time. This trend indicates a robust growth trajectory for the CNC Polishing Machines Market, driven by the electronics sector's evolving needs.

Focus on Customization and Flexibility

Customization and flexibility are becoming increasingly important in the CNC Polishing Machines Market. As manufacturers seek to differentiate their products, the ability to tailor polishing processes to specific requirements is essential. This trend is particularly evident in industries such as jewelry and medical devices, where unique finishes are crucial. The demand for CNC polishing machines that can accommodate various materials and shapes is on the rise. Recent analyses suggest that the market for customizable CNC machinery solutions is expected to grow by 15% annually. This focus on adaptability is likely to propel the CNC Polishing Machines Market forward, as companies invest in versatile polishing technologies.

Growth in Aerospace and Defense Applications

The aerospace and defense sectors are emerging as vital markets for the CNC Polishing Machines Market. The need for precision-engineered components in aircraft and defense systems necessitates high-quality polishing solutions. Recent reports suggest that the aerospace industry is expected to grow at a compound annual growth rate of 5% over the next five years, further driving the demand for CNC polishing machines. These machines are essential for achieving the stringent surface finish requirements mandated by regulatory bodies. As a result, the CNC Polishing Machines Market is poised to benefit from increased investments in aerospace manufacturing and maintenance.

Technological Advancements in CNC Polishing Machines

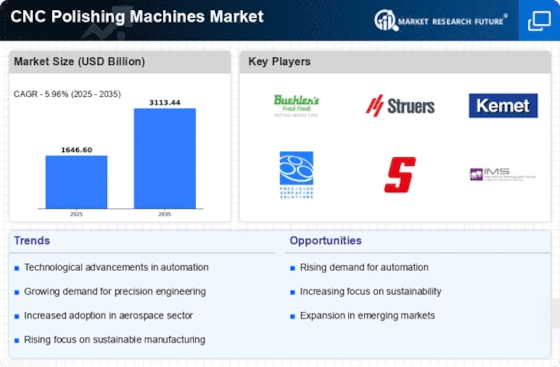

The CNC Polishing Machines Market is experiencing a surge in technological advancements that enhance precision and efficiency. Innovations such as automation and artificial intelligence are being integrated into polishing machines, allowing for higher throughput and reduced operational costs. For instance, the introduction of smart sensors enables real-time monitoring and adjustments, which minimizes errors and optimizes performance. According to recent data, the adoption of advanced CNC technologies is projected to increase productivity by up to 30% in various manufacturing sectors. This trend not only improves the quality of polished surfaces but also reduces waste, making it a pivotal driver in the CNC Polishing Machines Market.