Top Industry Leaders in the Cross Linked Polyethylene Market

Cross-Linked Polyethylene (XLPE) Market

The global Cross-Linked Polyethylene (XLPE) market is witnessing a dynamic and competitive landscape, driven by rising demand for high-performance cable insulation materials. the market attracts established players and new entrants alike. Here's an exploration of the key aspects shaping this competitive arena:

Competitive Strategies at Play:

-

Product Innovation: Players invest heavily in R&D to develop advanced XLPE grades with improved properties like enhanced flame retardancy, higher temperature resistance, and better mechanical strength. -

Geographic Expansion: Leading players are expanding their footprints in emerging markets like Asia Pacific and Latin America, capitalizing on the growing demand for infrastructure development. -

Mergers & Acquisitions: Strategic acquisitions and collaborations are on the rise, allowing players to access new technologies, markets, and customer segments. -

Sustainability Initiatives: As environmental concerns mount, companies are focusing on developing eco-friendly XLPE solutions made from recycled materials or bio-based sources. -

Cost Optimization: Players are optimizing production processes and exploring alternative feedstocks to reduce costs and maintain competitiveness.

Factors Influencing Market Share:

-

Product Portfolio: Offering a diverse range of XLPE grades catering to varied voltage levels, temperature resistance, and environmental requirements is crucial. -

Production Capacity and Cost Efficiency: Players with economies of scale and efficient manufacturing processes gain a competitive edge. -

Brand Reputation and Quality Assurance: Establishing a strong brand image and ensuring consistent quality through stringent quality control measures are essential. -

Geographical Presence: Having a global reach and catering to diverse regional demands is advantageous. -

Distribution Network and Customer Service: Building strong relationships with distributors and offering excellent customer service are key differentiators. -

Technological Innovation: Investing in R&D to develop improved XLPE compounds with enhanced properties like flame retardancy and higher operating temperatures is critical.

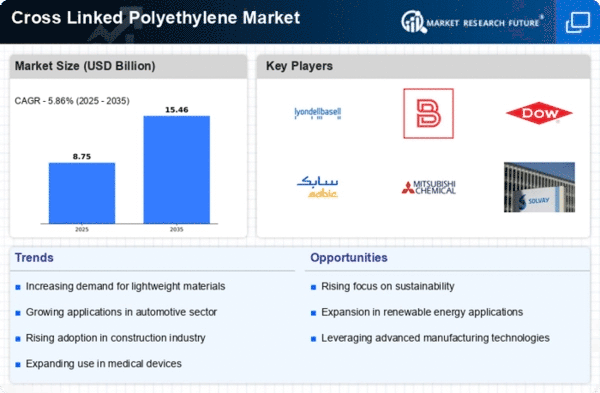

Key Players

-

Borealis AG (Austria)

-

Solvay (Belgium)

-

LyondellBasell Industries Holdings B.V. (The Netherlands)

-

PolyOne Corporation (US)

-

Exxon Mobil Corporation (US)

-

3H VINACOM CO., LTD (Vietnam)

-

Falcone Specialities AG (Switzerland)

-

HDC HYUNDAI EP COMPANY (South Korea)

-

SACO AEI Polymers (US), among others

Recent Developments :

March 2019: Subsea 7 and NKT have completed installation of the 163-km (101-mi) HV alternating current cable system taking power from the Norwegian mainland to the Martin Linge oil and gas field in the North Sea. It is the world’s longest submarine HVAC cable installation, NKT claimed. Operator Equinor and its partners selected the solution to reduce carbon dioxide emissions at the offshore complex by 200,000 metric tons/yr., compared with the alternative of power generators at the production complex. NKT designed, engineered, and manufactured a 145-kV three-core XLPE HVAC submarine cable and associated fiber optic links with a 55 MW capacity; and a 3.5-km (2.2-mi), 17.5-kV infield cable, which included 500 m (1,640 ft) of dynamic cable.