Global De-Agglomerating Equipment Market Overview

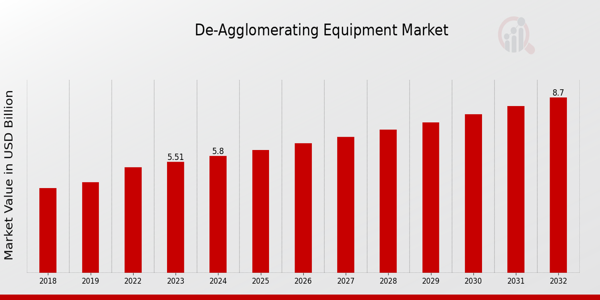

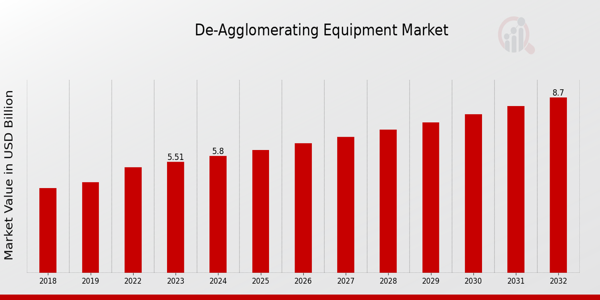

De-Agglomerating Equipment Market Size was estimated at 5.24 (USD Billion) in 2022. The De-Agglomerating Equipment Industry is expected to grow from 5.51(USD Billion) in 2023 to 8.7 (USD Billion) by 2032. The De-Agglomerating Equipment Market CAGR (growth rate) is expected to be around 5.2% during the forecast period (2024 - 2032).

Source Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Key De-Agglomerating Equipment Market Trends Highlighted

The De-Agglomerating Equipment Market is currently experiencing significant growth driven by the increasing demand for efficient processing in various industries. The push for better product quality and consistency has led manufacturers to recognize the importance of de-agglomeration in production processes. Innovations in technology are enhancing the capabilities of this equipment, allowing for finer particle size control and improved operational efficiency. Moreover, as industries lean toward sustainability, energy-efficient de-agglomerating solutions are gaining traction, making them essential for companies aiming to reduce their environmental footprint.

There are several opportunities to be explored in this market, particularly in emerging economies where industrialization is on the rise. As these regions expand their manufacturing capabilities, the need for advanced de-agglomerating equipment becomes critical. Additionally, advancements in materials science are creating opportunities for new applications in pharmaceuticals, food processing, and chemicals, opening new avenues for market growth. Companies that invest in research and development can create innovative solutions tailored to specific industry needs, further enhancing their market position. Recent trends show an increased focus on automated and smart de-agglomerating systems that integrate Industry 4.0 principles.

This shift toward automation is allowing for real-time monitoring and improved operational efficiency. Furthermore, a growing emphasis on customizability is evolving how equipment is designed and manufactured, enabling businesses to meet unique process specifications. As industries continue to adapt to new market dynamics, the demand for state-of-the-art de-agglomerating solutions is set to rise, making it a pivotal area for investment and advancement.

De-Agglomerating Equipment Market Drivers

Increasing Demand from Various Industries

The De-Agglomerating Equipment Market Industry is experiencing a robust rise in demand fueled by its extensive applications across various sectors, including pharmaceuticals, food processing, chemicals, and materials. As industries continue to evolve and advance technologically, the need for high efficiency and consistency in production flourishes. In the pharmaceutical industry, the requirement for precise particle size distribution is critical, as it directly impacts drug efficacy and bioavailability.

Similarly, in food processing, consumers are increasingly seeking products that are free from clumps and that maintain a desirable texture, thus necessitating the use of de-agglomerating equipment. The chemical industries also require precise control over particle sizes for optimal reactions and product quality, making de-agglomeration an essential part of their processes. Furthermore, rapid industrialization coupled with increased focus on product innovation and quality improvement is steering many manufacturers towards adopting advanced de-agglomerating solutions.

As these trends unfold, the De-Agglomerating Equipment Market is on a growth trajectory, with companies increasingly investing in efficient de-agglomerating technologies to meet the rising expectations of quality and consistency in their products. Such investments, driven by competitive pressures and the need for compliance with stringent quality standards, are also projected to significantly contribute to the market's growth as industries seek to enhance their operational efficacy while reducing production bottlenecks.

Technological Advancements in De-Agglomerating Equipment

The De-Agglomerating Equipment Market Industry is benefiting from rapid technological advancements that enhance the efficiency and effectiveness of de-agglomeration processes. Innovations in equipment design, materials, and control systems are providing manufacturers with sophisticated tools that allow for better performance metrics and adaptability in various production environments. For instance, the implementation of smart technologies and automation in de-agglomerators facilitates real-time monitoring and control over particle size, ensuring consistent quality in outputs.

Furthermore, these advancements are leading to reduced energy consumption and improved operational efficiency, making de-agglomerating equipment more cost-effective over the long term. As technology continues to evolve, the capability of de-agglomerating equipment to handle a wider variety of materials and improve processing times is expected to further stimulate market growth.

Growing Focus on Quality Control and Compliance

Within the De-Agglomerating Equipment Market Industry, there is an increasing emphasis on quality control and regulatory compliance across various sectors. Companies are under constant pressure to meet stringent quality standards set by regulatory bodies, particularly in the pharmaceutical and food industries. This heightened focus on quality necessitates the implementation of reliable de-agglomeration techniques to produce uniform particle sizes, which is fundamental to ensuring product safety and efficacy.

As manufacturers prioritize adherence to regulatory standards, the demand for advanced de-agglomerating equipment that ensures precise quality control is expected to rise significantly.

De-Agglomerating Equipment Market Segment Insights

De-Agglomerating Equipment Market Type Insights

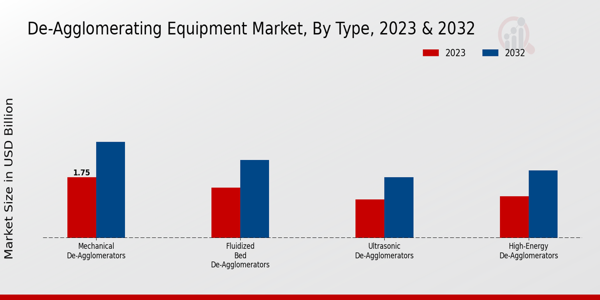

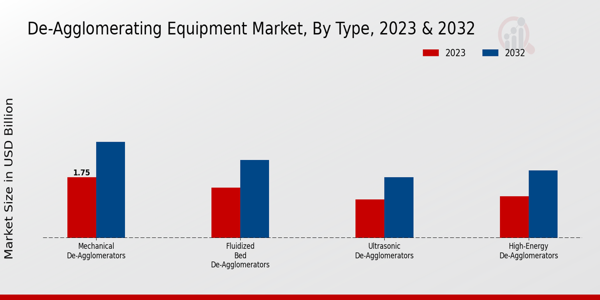

The De-Agglomerating Equipment Market, defined by its Type segmentation, showcases a robust landscape with significant growth potential. In 2023, the market demonstrated a total valuation of 5.51 USD Billion, reflecting a consistent demand for innovative de-agglomerating solutions across various industries. The segment is subdivided into four critical types Mechanical De-Agglomerators, Fluidized Bed De-Agglomerators, Ultrasonic De-Agglomerators, and High-Energy De-Agglomerators, each contributing uniquely to the overall dynamics of the market.

Among these, Mechanical De-Agglomerators hold a notable position, valued at 1.75 USD Billion in 2023 and projected to reach 2.77 USD Billion by 2032, making it a dominant force that addresses the conventional needs of material processing, particularly in pharmaceuticals and food processing industries.

Fluidized Bed De-Agglomerators also play a crucial role, with a valuation of 1.45 USD Billion in 2023. This type is significant due to its capacity to efficiently handle fine powders and enhance product quality. As industries increasingly prioritize uniformity in particle size distribution, demand for Fluidized Bed De-Agglomerators is expected to rise. Ultrasonic De-Agglomerators, valued at 1.11 USD Billion in 2023, are emerging as important assets, particularly in applications requiring delicate handling of materials. Their ability to operate at lower energy levels while effectively breaking up agglomerates resonates with the growing trend of sustainable processing methods.

High-Energy De-Agglomerators, valued at 1.2 USD Billion in 2023, signify the sector's advancement towards high-efficiency processing. The capability to process materials at a rapid pace represents a critical advantage, particularly in large-scale manufacturing. As the demand for more efficient and faster processing equipment surges, this type holds potential for substantial market growth. The De-Agglomerating Equipment Market exhibits trends towards automation and digital integration, influencing all types within the market. In line with evolving technology, these trends create continuous opportunities for product development and improvement.

Collectively, the various types within the market highlight vital avenues for growth, shaping the future of material processing across diverse sectors. Each type contributes distinctly to the market's expansion, with their market valuations and growth prospects indicating the important role they play in advancing industry standards.

Source Primary Research, Secondary Research, Market Research Future Database and Analyst Review

De-Agglomerating Equipment Market Application Insights

The De-Agglomerating Equipment Market is experiencing growth driven by its extensive applications across various industries, culminating in a market valuation of 5.51 USD Billion in 2023. This segment's robust performance is attributable to the demand for efficient material processing technologies that enhance productivity and ensure quality. In the pharmaceuticals sector, the need for precise material handling and uniformity in product formulation drives significant growth as companies prioritize safety and effectiveness. Meanwhile, the food and beverages industry emphasizes the importance of maintaining ingredient quality and consistency, thereby necessitating effective de-agglomeration techniques.

The chemical processing sector benefits from improved processing and handling of powders, promoting operational efficiency. Additionally, material handling applications are crucial, as they facilitate the smooth transfer and processing of bulk materials in various processes. Overall, the segmentation of the De-Agglomerating Equipment Market reflects its vital role across these industries, showcasing substantial opportunities for innovation and development in response to evolving market demands.

De-Agglomerating Equipment Market End Use Industry Insights

The De-Agglomerating Equipment Market is poised for steady growth within the End-Use Industry sector, with a market value of 5.51 USD Billion expected in 2023. This segment plays a crucial role across various industries, particularly in Cosmetics, where fine powder formulations demand precise particle size for superior product quality and performance. Agriculture is also significant as de-agglomerating equipment ensures uniform distribution of fertilizers and pesticides, enhancing their effectiveness. The Mining sector benefits from this equipment by optimizing ore processing and improving separation efficiency, which is vital for resource extraction.

In the Building Construction industry, de-agglomeration assists in the production of uniform mixtures for concrete and other materials, ensuring structural integrity. As the market continues to evolve, it showcases dynamic trends influenced by increasing demand for high-quality materials and sustainable practices, presenting opportunities for innovators and manufacturers in the De-Agglomerating Equipment Market industry. Overall, the market is driven by technological advancements and the growing need for material efficiency, with De-Agglomerating Equipment Market data indicating diverse applications across these key sectors.

The De-Agglomerating Equipment Market statistics illustrate how these industries collectively form a significant part of the overall market growth trajectory leading up to 2032.

De-Agglomerating Equipment Market Capacity Insights

The De-Agglomerating Equipment Market witnessed strong growth, valued at 5.51 billion USD in 2023. The capacity segment of this market can be categorized into several segments, notably small-scale, medium-scale, and large-scale, each playing a critical role in the overall market dynamics. The trend towards efficient material processing has led to increased demand across various sectors, with small-scale equipment gaining traction due to its flexibility and adaptability for smaller operations. Medium scale equipment is essential for industries scaling up operations, optimizing both efficiency and productivity.

Large-scale de-agglomerating equipment remains significant as major manufacturers seek advanced solutions for high throughput applications. The diverse applications across pharmaceuticals, chemicals, and food processing exemplify the importance of these capacity segments, impacting the De-Agglomerating Equipment Market revenue significantly. As the market evolves, it faces challenges such as rising raw material costs and regulatory compliance, yet opportunities remain in technological advancements and increasing industrial automation, making the analysis of De-Agglomerating Equipment Market segmentation more relevant than ever.

De-Agglomerating Equipment Market Regional Insights

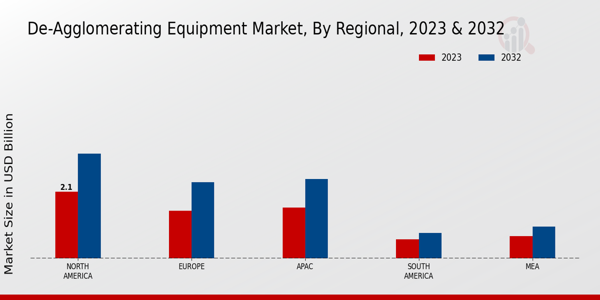

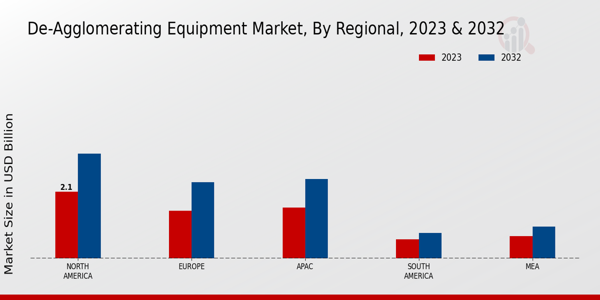

The De-Agglomerating Equipment Market is expected to witness significant activity across its regional segmentation. North America led the market with a valuation of 2.1 USD Billion in 2023, showcasing its majority holding in the industry. This dominance can be attributed to a well-established manufacturing sector and ongoing advancements in technology. Following North America, Europe is projected at 1.5 USD Billion, benefiting from a robust pharmaceutical and food processing industry that requires efficient de-agglomerating solutions.

The Asia-Pacific (APAC) region, valued at 1.6 USD Billion, reflects rapid industrialization and a growing demand for de-agglomerating equipment in various sectors like chemicals and materials processing.

South America, while smaller at 0.6 USD Billion, is emerging as a vital market due to increased investment in infrastructure and industrial growth. Lastly, the Middle East and Africa (MEA) market, valued at 0.7 USD Billion, presents opportunities owing to expanding oil and gas industries requiring specialized de-agglomerating solutions. The De-Agglomerating Equipment Market revenue is poised for growth, driven by these regional trends and their significance in the industry landscape.

Source Primary Research, Secondary Research, Market Research Future Database and Analyst Review

De-Agglomerating Equipment Market Key Players and Competitive Insights

The De-Agglomerating Equipment Market is characterized by a diverse array of players who operate within this niche field, offering an extensive range of machinery designed to reduce the size of powder particles while achieving optimal material flow properties. Competitive insights within this market highlight the importance of innovation, efficiency, and technological advancements as key drivers for success among manufacturers. The demand for de-agglomerating equipment has surged due to its applications across various industries, including pharmaceuticals, food processing, and chemical manufacturing. As players strive to capture market share, differentiation through product features, performance, and customer service becomes essential.

Detailed analysis of market trends, emerging competitors, and potential barriers to entry provides a comprehensive view of the landscape, enabling companies to strategically position themselves for growth.

Mikro Pulverizer has established itself as a formidable player within the De-Agglomerating Equipment Market. The company's strength lies in its renowned design and engineering capabilities, which are focused on delivering high-quality de-agglomerating solutions tailored to a broad spectrum of industrial needs. It is widely recognized for its robust performance, reliability, and efficiency in processing a variety of materials, making it a preferred choice among manufacturers seeking superior milling technology. Mikro Pulverizer's commitment to innovation ensures that it consistently develops advanced equipment that enhances productivity and minimizes operational costs for its clients.

Moreover, the company's extensive experience in different industrial applications and its strong customer service model further consolidate its presence and credibility in the market, allowing it to maintain a competitive edge.

Vortex Recycling is also making significant strides in the De-Agglomerating Equipment Market by focusing on sustainable practices that appeal to environmentally conscious industries. The company is known for its innovative recycling and de-agglomerating technologies that allow for the efficient processing of reclaimed materials. Vortex Recycling’s equipment features state-of-the-art design elements that not only optimize material recovery rates but also reduce energy consumption during operation, giving it a competitive advantage in markets where sustainability is paramount.

The firm's ability to provide solutions that enhance the recycling process positions it uniquely as a go-to partner for companies looking to improve their environmental impact while maintaining high-grade product quality. Its reputation for reliability and efficiency in operations strengthens its market position, fostering important business relationships in various sectors where de-agglomerating solutions are critical.

Key Companies in the De-Agglomerating Equipment Market Include

De-Agglomerating Equipment Market Industry Developments

Recent developments in the De-Agglomerating Equipment Market have underscored significant trends and advancements among key players. Companies like Mikro Pulverizer and Hosokawa Micron are focusing on the enhancement of their product lines to meet the increasing demand for finer materials, particularly in industries such as pharmaceuticals and food processing. Vortex Recycling and Glen Mills have reported investments in RD to innovate their de-agglomerating technologies, aiming to improve energy efficiency and processing speeds. Current affairs include increased market valuation, driven by heightened interest in sustainable practices and the push for circular economy principles within manufacturing sectors.

Notably, reports indicate potential mergers and acquisitions among the industry leaders, with companies such as Metso and Coperion exploring consolidation opportunities to enhance their service capabilities and expand market reach. Additionally, SWECO and Retsch are adapting to market conditions by diversifying their product offerings and entering new geographic markets. The growth outlook remains positive, reflecting an expanding application scope for de-agglomerating equipment across various sectors influenced by technological advancements and changing consumer preferences.

De-Agglomerating Equipment Market Segmentation Insights

De-Agglomerating Equipment Market Type Outlook

-

- Mechanical De-Agglomerators

- Fluidized Bed De-Agglomerators

- Ultrasonic De-Agglomerators

- High-Energy De-Agglomerators

De-Agglomerating Equipment Market Application Outlook

De-Agglomerating Equipment Market End Use Industry Outlook

De-Agglomerating Equipment Market Capacity Outlook

De-Agglomerating Equipment Market Regional Outlook

| Report Attribute/Metric |

Details |

| Market Size 2022 |

5.24(USD Billion) |

| Market Size 2023 |

5.51(USD Billion) |

| Market Size 2032 |

8.7(USD Billion) |

| Compound Annual Growth Rate (CAGR) |

5.2% (2024 - 2032) |

| Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Base Year |

2023 |

| Market Forecast Period |

2024 - 2032 |

| Historical Data |

2019 - 2023 |

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

Mikro Pulverizer, Vortex Recycling, Fritsch, Glen Mills, Avantor, Schmitt Industries, FLSmidth, Kason Corporation, Metso, Coperion, SWECO, Retsch, Siebtechnik Tema, Hosokawa Micron |

| Segments Covered |

Type, Application, End Use Industry, Capacity, Regional |

| Key Market Opportunities |

Rising demand in pharmaceuticals, Expansion in food processing, Increased automation trends, Growth in plastics recycling, and Advancements in material science. |

| Key Market Dynamics |

Technological advancements, Increasing demand for powder processing, Growing pharmaceutical industry, Rising investment in R, Expanding food and beverage sector |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ):

The De-Agglomerating Equipment Market is expected to be valued at 8.7 USD Billion in 2032.

The expected CAGR for the De-Agglomerating Equipment Market from 2024 to 2032 is 5.2%.

North America is projected to have the largest market share, valued at 3.3 USD Billion in 2032.

The market value for Mechanical De-Agglomerators is expected to reach 2.77 USD Billion in 2032.

Some major players include Mikro Pulverizer, Vortex Recycling, Fritsch, Glen Mills, and Avantor.

The market size for Fluidized Bed De-Agglomerators is expected to be 2.24 USD Billion in 2032.

The market for Ultrasonic De-Agglomerators is projected to grow to 1.75 USD Billion by 2032.

The forecasted market value for the APAC region is expected to be 2.5 USD Billion in 2032.

The market value for High-Energy De-Agglomerators is expected to rise to 1.94 USD Billion by 2032.

Challenges such as fluctuating raw material prices and technological advancements could impact market growth.