Top Industry Leaders in the Engineered Plastics Market

The engineered plastics market, is a dynamic arena where industry giants and niche players vie for dominance. With its robust growth, the market presents attractive opportunities, but also fierce competition. Let's delve into the strategies companies are employing, the factors dictating market share, and the latest developments shaping this fascinating landscape.

The engineered plastics market, is a dynamic arena where industry giants and niche players vie for dominance. With its robust growth, the market presents attractive opportunities, but also fierce competition. Let's delve into the strategies companies are employing, the factors dictating market share, and the latest developments shaping this fascinating landscape.

Strategies adopted by major players:

-

Product diversification: Leading players like SABIC, BASF, and Covestro are expanding their portfolios beyond traditional offerings like polyamides and polycarbonates. Emerging niches like bio-based and high-performance polymers are being actively pursued. -

Regional focus: Asia Pacific, fueled by booming automotive and electronics sectors, is a top priority. Companies are establishing production facilities and strengthening distribution networks in this region. -

Vertical integration: Forward integration into downstream applications like automotive components and medical devices is a key strategy for securing market share and margins. -

Sustainability initiatives: Growing environmental consciousness is driving investments in bioplastics and recycling technologies. Leading companies are showcasing circular economy solutions to gain an edge. -

Collaborations and acquisitions: Strategic partnerships and acquisitions are accelerating innovation and market reach. Examples include LANXESS acquiring Chemours' PEEK business and Solvay collaborating with Mitsubishi Chemical on bio-based polyamides.

Factors influencing market share:

-

Technological innovation: Companies with superior R&D capabilities and early access to breakthrough technologies hold an advantage. Developing lighter, stronger, and more sustainable materials can unlock new markets and applications. -

Cost competitiveness: Maintaining cost efficiency while adhering to stringent quality standards is crucial. Optimizing production processes and sourcing raw materials strategically are key for price leadership. -

Customer relationships: Building strong partnerships with OEMs and end-users fosters trust and long-term contracts. Tailoring solutions to specific needs and providing technical support strengthens customer loyalty. -

Regulatory compliance: Navigating the complex web of environmental and safety regulations across different regions is essential for smooth operations and market access.

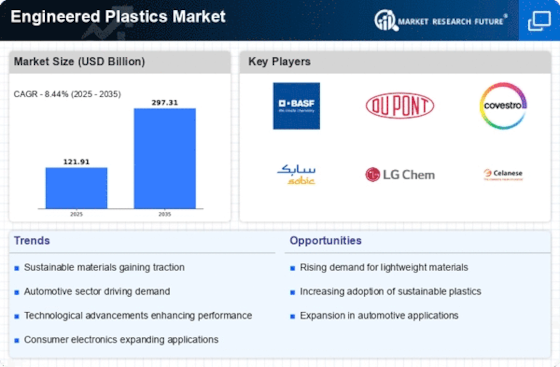

Key Players

- Covestro (Germany)

- BASF SE (Germany)

- Celanese Corporation (US)

- Dow Inc. (US)

- DSM Corporation (Netherlands)

- Solvay (Belgium)

- LG Chem (South Korea)

- LyondellBasell (Netherlands)

- ElringKlinger AG (Germany)

- Lanxess AG (Germany)

- Evonik Industries (Germany)

- SABIC (Saudi Arabia)

Recent News

Moreover, Covestro AG, in February 2023, produced Makrolon 3638 polycarbonate for healthcare and life sciences applications, including bio-pharmaceuticals packaging plastic bags and bottles which are used as drug delivery systems, cosmetic devices or wellness wearables, single-use containers, among others.

For example, in August 2022 glass, filled polypropylene grades – SABIC PP compound G3430X & SABIC PP compound G3440X – were introduced. They provide better performance and manufacturing capability to meet demanding requirements for automotive under-the-hood parts, look and feel parts, and interiors.

Consequently, in February 2022, BASF announced that it would market various PA66 compounds and polyphthalimide polymers like Solvay’s specialty Ultramid products following its acquisition of Solvay’s PA66 business. Technyl engineering plastics sold under BASF would still go by the reliable name Ultramid. A whole range of plastics with global customers includes PA66 compounds & Ultramid One J-PA66/6T based on PPA. Hence, BASF will enable its customers to realize future-oriented plastics solutions for their diverse applications, including consumer and household electronics, autonomous cars and e-mobility.

September in September 2021 Solvay announced the new thermoplastic composites (TPC) production plant at its site in Greenville, South Carolina.

Likewise, US-based Royal DSM revealed in February 2020 that it is refurbishing and expanding its high-performance materials compounding facility located in Evansville, Indiana. As a part of this initiative DSM will convert the factory for producing next-generation state-of-the-art materials like bio-based thermoplastics. These are essential factors driving the growth of the market over the projection period.

March 2022: companies such as BASF SE, a Germany-based international chemical company, acquired the overall polyamides business portfolio from Solvay SA. The acquisition triggered the broadening of the engineered plastics division and capabilities. These circumstances project a steady growth potential of engineered plastics ly over the foreseeable future.

January 2022: DSM Corporation validated an agreement with SRF Limited, an Indian multi-business chemical company, to acquire their engineered plastics business portfolio. SRF Limited had a portfolio diversion of over 200 grades of engineered plastics including Polycarbonate, Polyamide, PET, Polycarbonate, ABS, and more.

February 2021: The first-ever lawsuit concerning Dicamba-related products began in Cape Girardeau, Missouri. The lawsuit involves a peach farmer who alleged that Dicamba-based herbicides caused significant damage to his crops and trees.

March 2022: Celanese Corporation’s reorganization of Korea Engineering Plastics Co., Ltd., a globally recognized chemical company specializing in engineered materials business, was completed. Access to worldwide POM polymerization sites will help accelerate the growth of Celanese polyoxymethylene (POM) products around the world.