- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

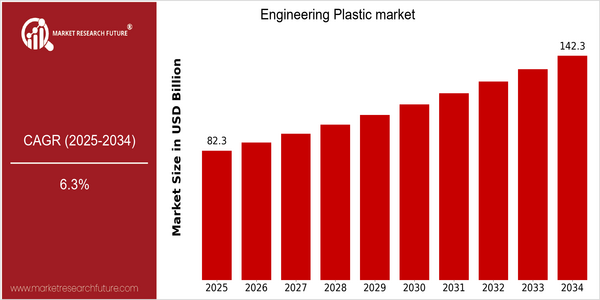

| Year | Value |

|---|---|

| 2025 | USD 82.31 Billion |

| 2034 | USD 142.3 Billion |

| CAGR (2025-2034) | 6.3 % |

Note – Market size depicts the revenue generated over the financial year

The engineering plastics market is expected to grow at a considerable rate. By 2025 it is expected to be worth $82.31 billion and by 2034 it is expected to be worth $142.30 billion. This represents a CAGR of 6.3% for the forecast period. The demand for lightweight and durable materials in the automobile, electrical and consumer goods industries is expected to be the main growth driver. The aim of all manufacturers is to increase the performance of their products and reduce costs and weight. Therefore, engineering plastics are becoming increasingly important in the design and manufacturing process. Also, the development of high-performance polymers and new processing methods will boost the market. In order to meet the growing demand, companies such as BASF, DuPont and SABIC are investing in research and development to create advanced materials that meet the requirements of modern applications. Strategic alliances and joint ventures are also contributing to the growth of the engineering plastics market. As the industry continues to focus on sustainability and energy efficiency, the engineering plastics market will continue to grow.

Regional Market Size

Regional Deep Dive

In recent years, the market for engineering plastics has grown rapidly in many regions, driven by rising demand from the end-use industries such as the automobile industry, the electrical industry, and the consumer goods industry. North America has a strong manufacturing base and a focus on innovation, whereas Europe emphasizes the importance of compliance with regulations and the importance of a strong reputation for quality. In the Asia-Pacific region, rapid industrialization and urbanization are driving rising demand for engineering plastics. In the Middle East and Africa, the development of infrastructure is gradually promoting the use of these materials, while in Latin America, recovery and investment in manufacturing are driving growth.

Europe

- In Europe, the focus on circular economy principles is driving the development of bio-based engineering plastics, with companies like BASF and Covestro leading initiatives to create sustainable alternatives.

- The European Union's stringent regulations on plastic waste are prompting manufacturers to invest in recycling technologies, which is expected to reshape the supply chain dynamics in the engineering plastics market.

Asia Pacific

- The Asia-Pacific region is witnessing a surge in demand for engineering plastics due to rapid urbanization and infrastructure development, with major players like Samsung and Toyota investing heavily in advanced materials.

- China's government initiatives to promote high-tech manufacturing are fostering innovation in engineering plastics, particularly in the electronics and automotive sectors, which is expected to enhance the region's competitive edge.

Latin America

- Latin America is experiencing a revival in manufacturing, with countries like Brazil and Mexico investing in engineering plastics to enhance product quality and performance in various industries.

- The region's unique cultural emphasis on sustainability is leading to increased interest in eco-friendly engineering plastics, with local companies exploring innovative solutions to meet consumer demand.

North America

- The North American market is heavily influenced by the automotive sector, with companies like General Motors and Ford increasingly utilizing engineering plastics to reduce vehicle weight and improve fuel efficiency.

- Recent regulatory changes aimed at reducing carbon emissions are pushing manufacturers to adopt more sustainable engineering plastics, with organizations such as the American Chemistry Council advocating for innovation in this area.

Middle East And Africa

- In the Middle East, the growing construction sector is driving demand for engineering plastics, with companies like SABIC focusing on developing high-performance materials for various applications.

- Government programs aimed at diversifying economies away from oil dependency are encouraging investments in manufacturing and technology, which is likely to boost the engineering plastics market in the region.

Did You Know?

“Engineering plastics can withstand temperatures ranging from -40°C to over 200°C, making them suitable for a wide range of applications, from automotive components to electronic devices.” — Plastics Technology Magazine

Segmental Market Size

The engineering plastics segment is a key component of the material market and is currently undergoing a steady upswing. Demand is growing as various industries expand. The trend toward lighter materials in the automobile and aircraft industries, coupled with more stringent government regulations aimed at improving energy efficiency, are the main forces driving this segment. The development of new polymer processing methods is also leading to the development of new engineering plastics with improved properties. The current state of the market for engineering plastics is one of maturity, with companies such as BASF and DuPont leading the way in both product development and applications. North America and Europe, the most important regions, lead the way in the development and use of these products, especially in the automobile, electrical, and consumer products industries. In the automobile industry, the main applications are in the areas of automobile components, electrical appliances, and industrial machinery, where long-term performance and a high degree of functionality are paramount. The push toward greater energy efficiency and the development of the circular economy are also driving growth in this segment, as manufacturers are looking for more sustainable alternatives. The development of 3D printing and new polymerization methods are also shaping the evolution of this segment, enabling the creation of custom-fit solutions and improving material properties.

Future Outlook

The engineering plastics market is set to experience significant growth between 2025 and 2034, with a projected CAGR of 6.3%. It is driven by the rising demand for lightweight, high-performance materials in a number of industries, such as the automobile, aeronautics, and electrical and electronics. As manufacturers increasingly focus on energy efficiency and the reduction of their carbon footprint, engineering plastics are becoming a must for reducing the weight of products and improving fuel economy. In the automobile industry, where regulations are tightening on the reduction of carbon dioxide emissions and fuel consumption, they are indispensable. Also driving growth is the development of bio-based engineering plastics and new polymer processing techniques. The integration of smart materials and the Internet of Things (IoT) into the manufacturing process is further broadening the scope of the applications for engineering plastics. In addition, government support for the use of sustainable materials is expected to accelerate penetration rates. As these changes are adopted by the industries, the engineering plastics market is evolving, and there are plenty of opportunities for growth and innovation.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 6.27% (2024-2032) |

Engineering Plastic Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.