Top Industry Leaders in the Glass Fiber Reinforced Concrete Market

Glass Fiber Reinforced Concrete, more than just a catchy acronym, has emerged as a versatile and increasingly popular construction material. Its lightweight strength, design flexibility, and durability weave a compelling narrative for architects, builders, and homeowners alike. But beneath the sleek surface of GFRC panels and countertops lies a dynamic market where established players and innovative newcomers vie for a share of the growing pie. Understanding the strategies, key factors shaping market share, and recent developments is crucial for navigating this intricate tapestry.

Glass Fiber Reinforced Concrete, more than just a catchy acronym, has emerged as a versatile and increasingly popular construction material. Its lightweight strength, design flexibility, and durability weave a compelling narrative for architects, builders, and homeowners alike. But beneath the sleek surface of GFRC panels and countertops lies a dynamic market where established players and innovative newcomers vie for a share of the growing pie. Understanding the strategies, key factors shaping market share, and recent developments is crucial for navigating this intricate tapestry.

Strategies Strengthening the Market Fabric:

-

Product Diversification: Moving beyond traditional architectural facades, GFRC manufacturers are expanding into new territory with furniture, landscape elements, and even nautical applications. Eldorado Stone, for instance, offers a diverse range of GFRC products beyond just cladding. -

Technological Advancements: 3D printing is weaving its magic into the GFRC landscape, enabling intricate designs and customized shapes with minimal waste. Lafarge, a major player, invests heavily in 3D printing technology for GFRC production. -

Sustainability Focus: Eco-conscious consumers are drawn to GFRC's use of recycled glass fibers and reduced carbon footprint compared to traditional concrete. Green Planet Architectural Products emphasizes the sustainability of its GFRC offerings. -

Regional Expansion: Emerging markets in Asia and the Middle East present significant growth potential. GCP Applied Technologies actively establishes partnerships and distribution networks in these regions. -

Strategic Partnerships and Collaborations: Joining forces with architects, design firms, and material suppliers can broaden market reach and expertise. Boral Building Products collaborates with renowned architects for innovative GFRC project applications.

Factors Weaving the Market's Tapestry:

-

Aesthetic Appeal and Design Versatility: GFRC's ability to mimic textures, shapes, and finishes pushes the boundaries of design, attracting architects and homeowners seeking unique aesthetics. Exterra Products Corporation capitalizes on the design flexibility of GFRC with its diverse range of textures and finishes. -

Durability and Performance: GFRC's resistance to weather, fire, and pests, coupled with its low maintenance requirements, makes it a cost-effective option in the long run. Cultured Stone, a leading GFRC manufacturer, highlights the material's longevity and minimal maintenance needs. -

Ease of Installation and Fabrication: Prefabricated GFRC panels offer faster installation times and reduced labor costs compared to traditional concrete casting. Saint-Gobain Weber, a major construction materials supplier, emphasizes the ease of installation with its GFRC product lines. -

Regulations and Building Codes: Meeting stringent fire safety and structural performance standards is essential for market access. USG Corporation ensures its GFRC products comply with all relevant building codes and regulations. -

Cost-Effectiveness: While initial material costs can be higher than traditional concrete, GFRC's lightweight nature translates to reduced transportation and installation costs, making it competitive in certain applications. Forterra Building Products positions its GFRC solutions as cost-effective alternatives for specific projects.

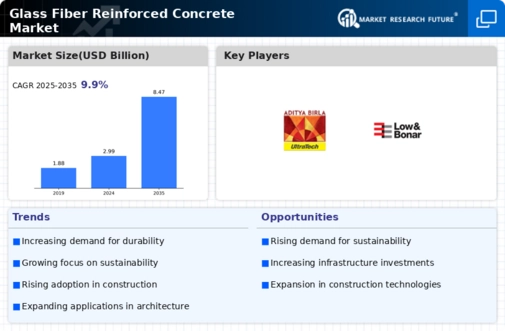

List of key major companies in the Glass Fiber Reinforced Concrete Market are:

Willis Construction Co., Inc. (U.S.),

Fibrex Construction Group (UAE),

Formglas Products Ltd. (Canada),

Clark Pacific (U.S.),

Ultratech Cement Ltd. (India),

Betofiber A.S. (Turkey),

BB Fiberbeton (Denmark),

Nanjing Beilida New Material System Engineering Co., Ltd. (China),

Stromberg Architectural (U.S.), Low & Bonar (U.K.) and

Loveld (Belgium).

Recent Developments:

-

October 2023: Nippon Electric Glass Corporation developed a new high-performance glass fiber for GFRC, offering increased strength and crack resistance. -

November 2023: LafargeHolcim partnered with INGRES to develop and commercialize GFRC solutions with enhanced fire resistance, aiming to address a critical safety concern in the construction industry. -

December 2023: Researchers at MIT unveiled a new type of GFRC reinforced with bio-based fibers, offering even greater sustainability and potential cost benefits.