-

Executive Summary

-

Scope of the Report

-

2.1

-

Market Definition

-

Scope of the Study

- Research Objectives

- Assumptions & Limitations

-

Markets Structure

-

Market Research

-

Methodology

-

Research Process

-

Primary Research

-

Secondary

-

Research

-

Forecast Model

-

Market Landscape

-

Supply Chain Analysis

- Raw Material Suppliers

- Manufacturers/Producers

- Distributors/Retailers/Wholesalers/E-Commerce

- Applications

-

Merchants

-

Porter’s Five Forces Analysis

- Threat of New Entrants

- Bargaining Power of Buyers

- Threat of Substitutes

- Intensity

-

4.2.3

-

Bargaining Power of Suppliers

-

of Competitive Rivalry

-

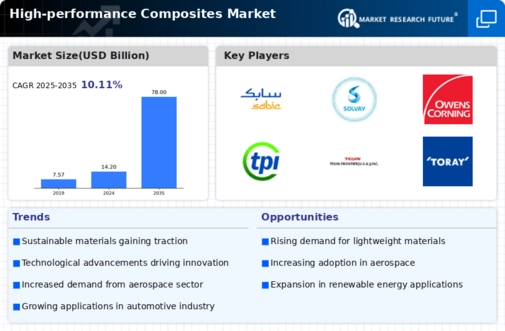

Industry Overview of High-Performance Composites Market

-

Introduction

-

Drivers

-

Restraints

-

Opportunities

-

Challenges

-

Market Trends

-

Introduction

-

Growth Trends

-

Impact Analysis

-

Global High-Performance Composites Market, by Material

-

Introduction

-

Resins

- Market Estimates & Forecast, 2023–2030

- Market Estimates & Forecast, by Region, 2023–2030

-

Fibers

- Market Estimates & Forecast, 2023–2030

- Market Estimates

-

& Forecast, by Region, 2023–2030

-

Global High-Performance Composites

-

Market, by Application

-

Introduction

-

Automotive

- Market

- Market Estimates & Forecast,

-

Estimates & Forecast, 2023–2030

-

by Region, 2023–2030

-

Aerospace

- Market Estimates &

- Market Estimates & Forecast, by Region,

-

Forecast, 2023–2030

-

Consumer Goods

- Market Estimates & Forecast,

- Market Estimates & Forecast, by Region, 2023–2030

-

Construction

- Market Estimates & Forecast, 2023–2030

- Market Estimates & Forecast, by Region, 2023–2030

-

Electronics

- Market Estimates & Forecast, 2023–2030

- Market Estimates

-

& Forecast, by Region, 2023–2030

-

Energy

- Market Estimates

- Market Estimates & Forecast, by Region,

-

& Forecast, 2023–2030

-

Others

- Market Estimates & Forecast, 2023–2030

- Market Estimates & Forecast, by Region, 2023–2030

-

Global

-

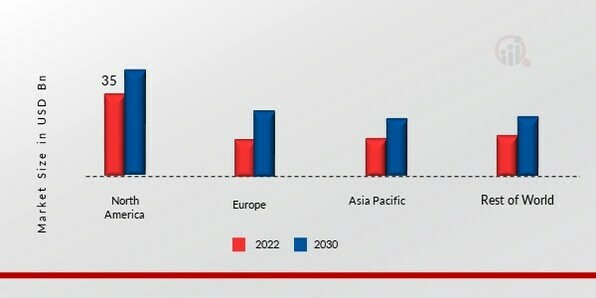

High-Performance Composites Market, by Region

-

Introduction

-

North

- Market Estimates & Forecast, 2023–2030

- Market

- Market Estimates

- US

- Canada

- Market Estimates & Forecast, 2023–2030

- Market

- Market Estimates

- Germany

- France

- Spain

- UK

- The Netherlands

- Russia

- Rest of Europe

-

America

-

Estimates & Forecast by Materials, 2023–2030

-

& Forecast by Application, 2023–2030

-

Estimates & Forecast, 2023–2030

-

by Materials 2023–2030

-

9.3

-

Europe

-

Estimates & Forecast by Materials, 2023–2030

-

& Forecast by Application, 2023–2030

-

Estimates & Forecast, 2023–2030

-

by Materials, 2023–2030

-

9.3.8

-

Italy

-

9.3.8.2

-

Market Estimates & Forecast by Materials, 2023–2030

-

Estimates & Forecast by Application, 2023–2030

-

9.3.9.1

-

Market Estimates & Forecast, 2023–2030

-

Forecast by Materials, 2023–2030

-

by Application, 2023–2030

-

Forecast, 2023–2030

-

9.3.9.5

-

Market Estimates & Forecast by Application, 2023–2030

-

Estimates & Forecast by Materials, 2023–2030

-

& Forecast by Application, 2023–2030

-

9.3.12.1

-

Market Estimates & Forecast, 2023–2030

-

& Forecast by Materials, 2023–2030

-

Forecast by Application, 2023–2030

-

Asia Pacific

- Market

- Market Estimates & Forecast

- Market Estimates & Forecast by Application,

- China

- India

- Japan

- Australia

- South Korea

- Rest of Asia Pacific

-

Estimates & Forecast, 2023–2030

-

by Materials, 2023–2030

-

9.4.6.5

-

Market Estimates & Forecast by Application, 2023–2030

-

& Forecast by Materials, 2023–2030

-

Forecast by Application, 2023–2030

-

& Forecast, 2023–2030

-

Materials, 2023–2030

-

9.4.10

-

New Zealand

-

9.4.10.2

-

Market Estimates & Forecast by Materials, 2023–2030

-

9.4.10.5Market

-

Estimates & Forecast by Application, 2023–2030

-

Estimates & Forecast by Materials, 2023–2030

-

9.4.10.5Market Estimates

-

& Forecast by Application, 2023–2030

-

& Forecast by Materials, 2023–2030

-

Forecast by Application, 2023–2030

-

Middle East & Africa

- Market Estimates &

- Market Estimates & Forecast

- Saudi Arabia

- UAE

- South

- Rest of the

- Market Estimates & Forecast, 2023–2030

- Market Estimates & Forecast by Materials, 2023–2030

-

9.5.1

-

Market Estimates & Forecast, 2023–2030

-

Forecast by Materials, 2023–2030

-

by Application, 2023–2030

-

& Forecast, 2023–2030

-

Materials, 2023–2030

-

9.5.7.5

-

Market Estimates & Forecast by Application, 2023–2030

-

Africa

-

9.5.8.2

-

Market Estimates & Forecast by Materials, 2023–2030

-

9.5.8.5Market

-

Estimates & Forecast by Application, 2023–2030

-

Middle East & Africa

-

9.5.9.

-

Market Estimates & Forecast by Application, 2023–2030

-

Latin America

- Market Estimates & Forecast, 2023–2030

- Market Estimates

- Market Estimates & Forecast

- Brazil

- Argentina

- Rest of Latin

-

& Forecast by Materials, 2023–2030

-

by Application, 2023–2030

-

& Forecast, 2023–2030

-

Materials, 2023–2030

-

9.6.6

-

Mexico

-

9.6.6.2

-

Market Estimates & Forecast by Materials, 2023–2030

-

Estimates & Forecast by Application, 2023–2030

-

America

-

9.6.7.2

-

Market Estimates & Forecast by Materials, 2023–2030

-

Estimates & Forecast by Application, 2023–2030

-

Competitive Landscape

-

Introduction

-

Market Key Strategies

-

Key Development Analysis

-

(Expansions/Mergers & Acquisitions/Joint Ventures/New Product Developments/Agreements/Investments)

-

Company Profiles

-

SABIC

- Company Overview

- Materials/Business Segment Overview

- Key

- SWOT Analysis

- Key Strategies

-

11.1.2

-

Financial Updates

-

Developments

-

BASF

- Company Overview

- Financial Updates

- Materials/Business

- Key Developments

- SWOT Analysis

-

SE

-

Segment Overview

-

11.2.6

-

Key Strategies

-

Solvay

- Company Overview

- Financial

- Materials/Business Segment Overview

- Key Developments

- SWOT Analysis

- Key Strategies

-

Updates

-

Owens Corning

- Financial Updates

- Materials/Business Segment

- Key Developments

- SWOT Analysis

- Key

-

11.4.1

-

Company Overview

-

Overview

-

Strategies

-

TPI Composites

- Company Overview

- Financial

- Materials/Business Segment Overview

- Key Developments

- SWOT Analysis

- Key Strategies

-

Updates

-

Huntsman International

- Company Overview

- Financial Updates

- Materials/Business

- Key Developments

- SWOT Analysis

-

LLC

-

Segment Overview

-

11.6.6

-

Key Strategies

-

TEIJIN LIMITED

- Company Overview

- Materials/Business Segment Overview

- Key

- SWOT Analysis

- Key Strategies

-

11.7.2

-

Financial Updates

-

Developments

-

SGL

- Company Overview

- Financial Updates

- Materials/Business

- Key Developments

- SWOT Analysis

-

Group

-

Segment Overview

-

11.8.6

-

Key Strategies

-

Hexcel Corporation

- Company Overview

- Materials/Business Segment Overview

- Key

- SWOT Analysis

- Key Strategies

-

11.9.2

-

Financial Updates

-

Developments

-

Albany

- Company Overview

- Financial Updates

- Materials/Business Segment Overview

- Key Developments

- Key Strategies

-

International Corporation

-

11.10.5

-

SWOT Analysis

-

TORAY INDUSTRIES, INC.

- Financial Updates

- Materials/Business

- Key Developments

- SWOT Analysis

-

11.11.1

-

Company Overview

-

Segment Overview

-

11.11.6

-

Key Strategies

-

Arkema

- Company Overview

- Financial

- Materials/Business Segment Overview

- Key Developments

- SWOT Analysis

- Key Strategies

-

Updates

-

3M

- Company

- Financial Updates

- Materials/Business Segment

- Key Developments

- SWOT Analysis

- Key

-

Overview

-

Overview

-

Strategies

-

ARGOSY INTERNATIONAL

- Company Overview

- Materials/Business Segment Overview

- SWOT Analysis

- Key Strategies

- Company Overview

- Financial

- Materials/Business Segment Overview

- Key Developments

- SWOT Analysis

- Key Strategies

-

11.14.2

-

Financial Updates

-

11.14.4

-

Key Developments

-

11.15.

-

Northrop Grumman Corporation

-

Updates

-

Conclusion

-

LIST

-

OF TABLES

-

Global High-Performance Composites Market, by Region, 2023–2030

-

North America: High Performance Composites Market, by Country, 2023–2030

-

Europe: High Performance Composites Market, by Country, 2023–2030

-

Asia-Pacific: High Performance Composites Market, by Country, 2023–2030

-

Middle East & Africa: High Performance Composites Market, by Country,

-

Latin America: High Performance Composites Market,

-

by Country, 2023–2030

-

High Performance Composites Materials Market,

-

by Region, 2023–2030

-

North America: High Performance Composites

-

Materials Market, by Country, 2023–2030

-

Europe: High Performance

-

Composites Materials Market, by Country, 2023–2030

-

Asia-Pacific:

-

High Performance Composites Materials Market, by Country, 2023–2030

-

Table

-

Middle East & Africa: High Performance Composites Materials Market, by Country,

-

Latin America: High Performance Composites Materials

-

Market, by Country, 2023–2030

-

High Performance Composites Materials

-

Market, by Region, 2023–2030

-

North America: High Performance

-

Composites Materials Market, by Country, 2023–2030

-

Europe: High

-

Performance Composites Materials Market, by Country, 2023–2030

-

Table

-

Asia-Pacific: High Performance Composites Materials Market, by Country, 2023–2030

-

Middle East & Africa: High Performance Composites Materials Market,

-

by Country, 2023–2030

-

Latin America: High Performance Composites

-

Materials Market, by Country, 2023–2030

-

High Performance Composites

-

Application Market, by Region, 2023–2030

-

North America: High

-

Performance Composites Application Market, by Country, 2023–2030

-

Table

-

Europe: High Performance Composites Application Market, by Country, 2023–2030

-

Asia-Pacific: High Performance Composites Application Market, by Country,

-

Middle East & Africa: High Performance Composites

-

Application Market, by Country, 2023–2030

-

Latin America: High

-

Performance Composites Application Market, by Country, 2023–2030

-

Table

-

Global Materials Market, by Region, 2023–2030

-

Global Application

-

Market, by Region, 2023–2030

-

North America: High Performance

-

Composites Market, by Country, 2023–2030

-

North America: High

-

Performance Composites Market, by Materials, 2023–2030

-

North

-

America: High Performance Composites Market, by Application, 2023–2030

-

Europe: High Performance Composites Market, by Country, 2023–2030

-

Europe: High Performance Composites Market, by Materials, 2023–2030

-

Europe: High Performance Composites Market, by Application, 2023–2030

-

Asia-Pacific: High Performance Composites Market, by Country, 2023–2030

-

Asia-Pacific: High Performance Composites Market, by Materials, 2023–2030

-

Asia-Pacific: High Performance Composites Market, by Application, 2023–2030

-

Middle East & Africa: High Performance Composites Market, by Country,

-

Middle East & Africa: High Performance Composites

-

Market, by Materials, 2023–2030

-

Middle East & Africa: High

-

Performance Composites Market, by Application, 2023–2030

-

Latin

-

America: High Performance Composites Market, by Country, 2023–2030

-

Table

-

Latin America: High Performance Composites Market, by Materials, 2023–2030

-

Latin America: High Performance Composites Market, by Application, 2023–2030

-

LIST OF FIGURES

-

High Performance Composites Market Segmentation

-

Forecast Methodology

-

Porter’s Five Forces Analysis

-

of High-Performance Composites Market

-

Supply Chain of High-Performance

-

Composites Market

-

Share of High-Performance Composites Market, by

-

Country, 2023 (%)

-

Global High-Performance Composites Market, 2023–2030

-

Sub Segments of Materials

-

High Performance Composites Market

-

size, by Materials, 2023 (%)

-

Share of High-Performance Composites

-

Market, by Materials, 2023–2030

-

Sub Segments of Materials

-

Sub Segments of Application

-

High Performance Composites

-

Market size, by Application, 2023 (%)

-

Share of High-Performance Composites

-

Market, by Application, 2023–2030

Source: Secondary Research, Primary Research, Market Research Future Database, and Analyst Review

Source: Secondary Research, Primary Research, Market Research Future Database, and Analyst Review

Leave a Comment