Market Analysis

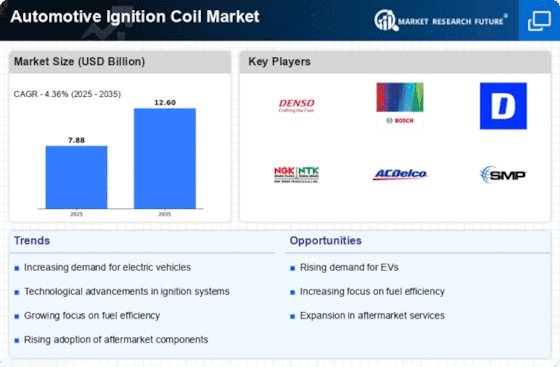

Automotive Ignition Coil Market (Global, 2024)

Introduction

The market for ignition coils is an important part of the automobile industry. It plays a key role in the ignition system of the internal-combustion engine. The development of vehicles is based on a combination of technological progress and the growing requirements of consumers for increased performance and efficiency. The market for ignition coils is very diverse, encompassing a wide range of products from the traditional ignition coil to the coil-on-plug system to smart solutions. It also covers a wide range of vehicles from cars to trucks. The growing trend towards electric and hybrid vehicles is also influencing the market for ignition coils. This is driving manufacturers to develop new products and solutions to meet the changing needs of the industry. Also, an increase in vehicle production and an increased focus on vehicle maintenance and repair services will drive the demand for ignition coils. This will make the market for ignition coils a dynamic and competitive one. The market for ignition coils will continue to grow. Hence, it is important for market participants to understand the complexities of this market to take advantage of the emerging opportunities and to respond to the challenges posed by technological progress and changing consumer preferences.

PESTLE Analysis

- Political

- In 2024, the auto industry is under the strong influence of government regulations that are trying to reduce exhaust emissions and promote the use of electric vehicles. In Europe, for example, the goal is to reduce the carbon dioxide emissions from cars by 55% by 2030, and this directly affects the production of engines with spark plugs, which are replaced by EV technology. In the United States, $ 7.5 billion is allocated for the expansion of EV charging stations, which will also shift the focus away from conventional auto parts, including spark plugs.

- Economic

- The global automobile market is expected to fluctuate as a result of the changing economic conditions in the different regions. The average price of gasoline in the United States in 2024 is expected to be around $1.25 per gallon, which is expected to influence consumers’ preferences for fuel-efficient vehicles. The automobile industry in Asia-Pacific is expected to contribute around $1.2 billion to the global economy, indicating the importance of the region in the manufacture of automobiles and the demand for ignition coils for internal-combustion vehicles.

- Social

- The consumers' preferences are changing towards more efficient and sustainable vehicles, with a significant increase in the use of hybrid and electric cars. In 2024, according to our survey, 60% of American consumers will buy an EV as their next car. This may lead to a decrease in demand for conventional ignition coils. In addition, manufacturers are responding to the growing awareness of the environment by developing more eco-friendly ignition coils that are in line with the expectations of consumers.

- Technological

- Advances in automobile technology are affecting the market for ignition coils in a major way. In 2024, the introduction of smart ignition systems that use sensors and microcontrollers to optimize the performance of engines and improve fuel economy is expected to significantly boost the market. Also, the use of high-voltage coils, some of which can produce up to 40,000 volts, is increasing. This improves the reliability of the spark and the performance of the engine. This technological change is forcing manufacturers to invest in research and development in order to remain competitive.

- Legal

- Regulations governing automobile emissions and safety standards are becoming more and more stringent. In the United States, for example, the National Highway Traffic Safety Administration has set new standards for emissions by 2024. These standards may affect the design and performance of ignition coils. The European Union has also imposed a ban on the use of hazardous substances in automobile components. If manufacturers want to sell their products in Europe, they must comply with REACH.

- Environmental

- The automobile industry is under pressure to reduce its carbon footprint and to make its production methods more sustainable. It is estimated that the production of automobile components, including coils, will produce a CO2emissions of approximately one million tons in 2024. In order to reduce these emissions, many manufacturers are adopting greener production methods, such as the use of recyclable materials and the reduction of waste, in order to achieve their sustainable development goals. Also, the upcoming shift towards electric vehicles is expected to reduce the emissions associated with the production of coils for internal combustion engines.

Porter's Five Forces

- Threat of New Entrants

- The barriers to entry into the car-ignition coil market are moderate, owing to the need for specialized technology and manufacturing capabilities. The market is dominated by established players, but there are opportunities for new entrants to develop niche products or new technology. However, the high initial investment and the established brand loyalty of the established companies can deter many potential entrants.

- Bargaining Power of Suppliers

- The bargaining power of the suppliers in the market for automobile igni- tion coils is relatively low. There are many suppliers of the components and the materials used in the manufacture of the coils, which creates a competitive situation. Suppliers can easily change suppliers if necessary, and thus have little influence on the prices and terms of the individual suppliers. Suppliers are also further weakened by the availability of alternative materials and production processes.

- Bargaining Power of Buyers

- The bargaining power of the buyers of the automobile ignition coils is high because of the large number of competitors and the low cost of changing suppliers. The buyers can therefore negotiate better prices and terms with the many manufacturers of the similar products. Moreover, the growing demand for high-quality and efficient coils gives them further negotiating power.

- Threat of Substitutes

- The threat of substitutes in the automobile spark-plug market is moderate. There are alternative spark-plug systems, such as the distributor-less system, but these are not used on all types of vehicles. The development of electric and hybrid vehicles could, however, eventually result in a reduced need for spark-plugs. The overall impact of substitutes will depend on the development of technology and the prevailing market trends.

- Competitive Rivalry

- Competition in the market for automobile coils is very keen, with several leading companies competing for market share. The presence of several manufacturers has given rise to a highly competitive situation, based on price, quality and innovation. The companies are constantly investing in research and development to improve their products and maintain a competitive edge. Competition between the companies is so keen that it can sometimes lead to price wars and a further intensification of the competition.

SWOT Analysis

Strengths

- High demand for ignition coils due to increasing vehicle production and sales.

- Technological advancements leading to improved efficiency and performance of ignition coils.

- Strong presence of established manufacturers with extensive distribution networks.

Weaknesses

- High competition leading to price wars and reduced profit margins.

- Dependence on the automotive industry, which is subject to economic fluctuations.

- Limited awareness among consumers regarding the importance of ignition coil maintenance.

Opportunities

- Growth in electric vehicle (EV) market creating demand for specialized ignition coils.

- Expansion into emerging markets with rising automotive sales.

- Potential for innovation in materials and designs to enhance product performance.

Threats

- Increasing adoption of alternative ignition technologies may reduce demand.

- Economic downturns affecting consumer spending on automotive parts.

- Regulatory changes and environmental concerns impacting manufacturing processes.

Summary

The Automotive Ignition Coil Market in 2024 will be characterized by strong demand driven by vehicle production and technological advancements. However, the market will also be challenged by high competition and the economy's dependence on the market. Opportunities are expected to arise from the growing electric vehicle market and emerging markets. However, newer technologies and regulations could also affect the market's development. Strategic focus on innovation and market expansion will be key for market players to succeed.

Leave a Comment