- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

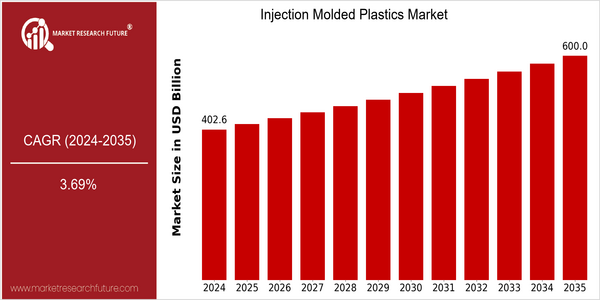

Injection Molded Plastic Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 402.57 Billion |

| 2035 | USD 600.0 Billion |

| CAGR (2025-2035) | 3.69 % |

Note – Market size depicts the revenue generated over the financial year

Injection moulding is a process in which the plastic is melted and injected into the mould. The injection moulding industry is estimated to be worth £402.57 billion in 2024, and to grow to £600 billion in 2035. The growth rate is a CAGR of 3.69% from 2025 to 2035, which shows a steady growth, mainly due to the growing demand from various industries. The injection moulding industry has seen a lot of changes, including the use of lightweight materials in the automotive industry, the development of injection moulding technology, and the increasing emphasis on sustainable and recyclable plastic products. The injection moulding industry is highly competitive, and the leading companies such as BASF, DuPont, and SABIC are constantly investing in new technology and establishing strategic cooperative relations to expand their product portfolio and market share. , for example, is mainly developing bio-based plastics and improving the efficiency of the production process. In addition, there are many research institutions and companies that work together to develop new materials for the consumer goods, medical, and electronics industries. These strategic initiatives are expected to further promote the development of the injection moulding industry, and the market is expected to grow as expected.

Regional Deep Dive

The injection molding of plastics market is growing at a fast pace, driven by the increasing demand from the end-use industries, such as the automobile, consumer goods, and health care industries. North America is characterized by the adoption of advanced manufacturing techniques and a strong focus on sustainability, while Europe is characterized by the emphasis on regulatory compliance and innovation in materials. Asia-Pacific is characterized by the rapid urbanization and industrialization, which is resulting in the high demand for injection molded products. Middle East and Africa are experiencing growth due to the development of the infrastructural sector, while Latin America is gradually adopting injection molding technology, which is influenced by the economic recovery and the increased investment in manufacturing.

North America

- The United States is leading in the field of advanced production technology, particularly in the field of automobiles. Ford and General Motors are utilizing injection molding to produce light components.

- In the past few years, however, due to stricter regulations and the implementation of new standards, manufacturers have been obliged to adopt more sustainable practices, which has led to a greater use of biodegradable plastics. BASF is a leading example of this.

- In the wake of the growth of e-commerce, the need for packaging has grown and companies such as Amcor have developed injection-moulded packaging to meet this demand.

Europe

- The European Union's Green Deal is driving innovations in the injection-moulded plastics market with the aim of reducing plastic waste and promoting the use of recycled materials. And companies such as Covestro are developing sustainable materials.

- In Germany, where the use of these materials is still in its infancy, there are also important R & D activities in the field of high-performance plastics, especially in the field of automobiles and aeronautics.

- Similarly, the use of bioplastics is booming in the region. The European Bioplastics Association, for example, is promoting the use of these sustainable materials in injection moulding.

Asia-Pacific

- The rapid development of China's industry and urbanization is mainly reflected in the use of injection molding machines, especially in the automobile and electrical appliance industries. BYD is the leader in the field of electric cars.

- Among the many things that have contributed to this growth is the Make in India program, which has encouraged the development of local production and the use of injection molding, which has benefited companies such as Reliance Industries.

- The region is undergoing a shift to smart manufacturing, with automation and IoT enhancing injection molding efficiency.

MEA

- The United Arab Emirats, which are investing heavily in the construction of public works, are finding that the demand for injection-moulded plastics for use in construction and packaging has increased, and that companies like Emirates Global Aluminium have begun to diversify into plastic products.

- South Africa is a country where the environment is becoming a priority. The regulatory framework has been evolving to promote the concepts of sustainable development and to encourage local manufacturers to adopt eco-friendly practices.

- In the rapidly developing market of the Middle East, the demand for consumer goods is rising, and companies are investing in injection-moulded plastics packaging.

Latin America

- Brazil is experiencing a new manufacturing boom, and government incentives are helping to boost the local plastics industry, benefiting companies like Braskem, which specializes in sustainable plastic production.

- The region is experiencing a shift towards lightweight construction in the automobile industry, where companies like Volkswagen are investing in injection moulding to reduce fuel consumption.

- The influx of foreign capital into the area has led to the introduction of more advanced injection moulding technology, which has led to improvements in the quality of the products and the capacity to produce.

Did You Know?

“The injection moulding of plastics allows complex shapes to be produced and gives considerable material savings, and the waste is reduced to a minimum.” — Plastics Industry Association

Segmental Market Size

The injection-moulded plastics segment is of particular importance to the plastics industry as a whole. It is currently experiencing steady growth, driven by rising demand in a variety of industries. This is in turn a consequence of a growing preference among consumers for lightweight and durable materials, as well as the implementation of increasingly stricter regulations, which encourage the use of recycled plastics. Also driving growth are advances in manufacturing technology, such as automation and the integration of 3D printing. These are improving both production efficiency and the quality of products.

Currently, the use of injection-moulded plastics is at a high level. Leading companies such as BASF and DuPont are implementing innovations in the automotive and consumer goods industries. Typical applications are components for automobiles, medical devices and food containers, where the need for precision and individuality is particularly high. And the macro-economic trends towards a circular economy and sustainable use are accelerating growth and causing manufacturers to invest in biodegradable and recyclable materials. In the field of CAD and simulation, the trend towards more efficient design and production is also shaping the market.

Future Outlook

From 2024 to 2035, the injection-molded plastics market is expected to increase from about 402 billion to 600 billion, with an average annual growth rate of 3.69%. The main reason for this is the increasing demand for lightweight and durable materials in the automobile, home appliances, and health industries. As the manufacturers attach importance to the environment, the use of bio-plastics and recycled plastics will increase, which will also promote the development of the injection-molded plastics industry. By 2035, the proportion of sustainable materials in the injection-molded plastics market will exceed 20%, and the injection molding industry will be more and more "green".

Also, the upcoming technological developments such as automation and smart manufacturing will play an important role in shaping the future of the injection molding industry. The development of 3D printing and advanced injection molding techniques is expected to improve the efficiency of production and reduce the waste of materials, which will further stimulate the industry to invest. In addition, government policies aimed at reducing the use of plastics and promoting the development of plastics industry will also have an impact on the market and stimulate the industry to innovation and change. The injection molding industry will diversify its products and increase its focus on the use of high-end, high-performance and special plastics that meet the industry's strict standards. In a word, the injection molding industry will change a lot in the next few years, driven by a combination of technological development, green development and changes in consumer habits.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 311.25 Billion |

| Growth Rate | 5.87% (2024-2032) |

Injection Molded Plastic Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.