Top Industry Leaders in the Lithium Hexafluorophosphate Market

Lithium hexafluorophosphate (LiPF6), the critical electrolyte salt powering rechargeable lithium batteries, This electrifying landscape hums with innovation and fierce competition, as established players and nimble newcomers jostle for market share. Let's delve into the strategies, factors, and trends shaping the future of this electrifying sector.

Lithium hexafluorophosphate (LiPF6), the critical electrolyte salt powering rechargeable lithium batteries, This electrifying landscape hums with innovation and fierce competition, as established players and nimble newcomers jostle for market share. Let's delve into the strategies, factors, and trends shaping the future of this electrifying sector.

Market Share Strategies:

-

Vertical Integration: Leading players like Do-Fluoride Chemicals and Central Glass are integrating upstream raw material sourcing and downstream battery manufacturing, ensuring quality control and cost competitiveness. -

Product Specialization: Offering customized LiPF6 grades with tailored thermal stability and ionic conductivity for specific battery applications, like Stella Chemifa's high-purity options for electric vehicles, is key to differentiation. -

Technological Advancements: Pioneering new production processes (think JiangSu Bicon's low-energy synthesis) and developing next-generation LiPF6 alternatives like lithium bis(fluorosulfonyl)imide (LiFSI) for enhanced performance and safety, like Tjanjin Jinniu's offering, is crucial for future success. -

Regional Expansion: Targeting booming markets like Asia-Pacific and Europe, driven by government incentives and electric vehicle adoption, presents significant opportunities. Guangzhou Tinci Materials' expansion into Europe exemplifies this trend.

Factors Influencing Market Share:

-

Fluctuating Raw Material Costs: Volatility in the prices of key raw materials like lithium fluoride and hexafluorophosphoric acid can impact profit margins and product pricing. -

Evolving Battery Technologies: The rise of solid-state batteries requiring different electrolytes challenges manufacturers to adapt and potentially develop new LiPF6 formulations. -

Stringent Environmental Regulations: Restrictions on waste disposal and hazardous materials in some regions, like Europe's REACH regulations, influence production processes and material choices. -

Geopolitical Landscape: Concerns about supply chain disruptions and resource availability, particularly for lithium, can impact market dynamics and stability.

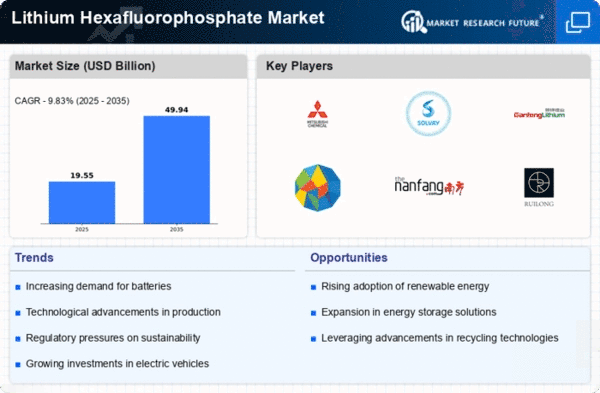

Key Players

- FPC

- Do-fluoride Chemicals

- Tianjin Jinniu, Tinci

- Jiujiujiu

- Kanto Denka Kogyo

- Foosung, Chuo-glass

- Stella Chemifa

- MORITA

- Central Glass

- Formosa Plastics

Recent Developments :

Nov 2021 - BYD, a prominent domestic electric vehicle (EV) and power battery maker, has struck a strategic collaboration deal with China's diversified chemical firm Do-Fluoride New Materials to supply lithium hexafluorophosphate (LiPF6) for the next four years. Between December 2025 and January 2022, Do-Fluoride will provide BYD with no less than 56,050t of LiPF6. Other specifics, such as purchasing costs, were kept under wraps. LiPF6 is an important feedstock for making lithium-ion battery electrolytes. Power battery producers have been beefing up their feedstock supplies for electrolyte synthesis in addition to cathode and anode components. In July, BYD inked a new purchase agreement with Do-Fluoride for a total of 6,460t of LiPF6.

Aug 2021 - Researchers from Monash University in Australia collaborated with Calix Ltd, an industrial solutions provider, to develop novel chemistry that addresses the safety and performance challenges that have stymied advances in higher-capacity batteries for energy storage and automotive applications. The researchers describe a new lithium salt that, by replacing hexafluorophosphate salt, may be able to overcome current electrolyte design problems. Lithium hexafluorophosphate, the lithium salt now used in Li-ion batteries, is poisonous and poses fire and safety risks. Because of their small size, this risk is largely lessened in small portable devices. Large battery packs, such as those used in electric vehicles and outdoor grid-scale energy storage systems, pose a greater fire risk.

In 2024, Honeywell International announced its plan to spend $84 million so as to expand their production base situated in Kansas, USA.

May 2023: Iolitec has just released the news that they have improved on their technology of making ionic liquids used in lithium-ion batteries of high performance. These developments are designed to improve the functioning and safety of LiPF6, which should encourage greater use of electric vehicles and storage systems for renewable energy.

January 2023: Guangzhou Tinci Materials Technology Company Limited has extended its capacity for lithium battery materials, including LiPF6, through investing in new facilities. This is a response to the increasing market demand for electric cars (EVs) and energy storage systems globally. The company has always had a focus on process improvement necessary for boosting efficiency and output.

September 2022: Merck has increased its range of high-purity lithum-ion battery materials through investing in research and development, including LiPF6. This is an extension aimed at supporting the growing EV market while advancing towards advanced materials for sustainable technologies, as stated by Merck's strategic frameworks.

March 2022: Foosung Co., Ltd., Koura and the Mayor of Kędzierzyn-Koźle Poland went into a three-party agreement to establish a production facility responding to surging demands for inorganic fluorine compounds utilized in lithium-ion batteries. By enhancing the supply chain for lithium battery materials within Europe, this project will foster regional economic growth.

In 2021, LANXESS announced that it will produce electrolyte formulation for lithium-ion batteries targeting Guangzhou Tinci Materials Technology Co., a Chinese firm, before 2022 ends.