- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

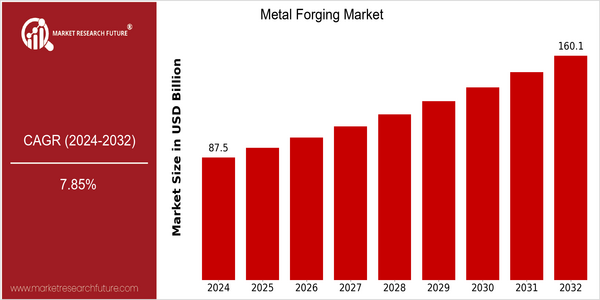

| Year | Value |

|---|---|

| 2024 | USD 87.5069 Billion |

| 2032 | USD 160.12 Billion |

| CAGR (2024-2032) | 7.85 % |

Note – Market size depicts the revenue generated over the financial year

Metal forging is a rapidly growing market, which is expected to reach a size of $87,509,922,600 by 2024, and is forecast to reach $ 157,073,600 by 2032. This rapid growth is driven by a CAGR of 7.85% during the forecast period. The main driving force for this expansion is the increasing demand for forged components in various industries such as automobiles, aircrafts, and construction. Also, as the manufacturers are looking to improve the performance and lifespan of their products, they are adopting advanced forging techniques such as precision forging and automation. This has further augmented the growth of the market. The major players in the metal forging industry, such as Arconic, Thyssenkrupp AG, and Precision Castparts Corp., are focusing on the development of new products and the formation of strategic alliances to strengthen their production capacity and market share. For example, the recent collaborations for the development of light-weight forged components for electric vehicles show the response of the industry to the changing demands of consumers and the regulatory framework. Industry 4.0, including IoT and AI, is expected to optimize the production process, reduce costs, and improve product quality, thus contributing to the overall growth of the metal forging market.

Regional Market Size

Regional Deep Dive

Among the metals which are forged are iron, copper, brass, bronze, aluminum, iron, lead, zinc, and the metals which are wrought from them are iron, copper, brass, zinc, lead, aluminum, and iron. The wrought metals are iron, brass, zinc, lead, aluminum, and iron. The wrought metals are copper, brass, zinc, lead, aluminum, iron, and aluminum. Among the wrought metals are iron, copper, brass, zinc, lead, aluminum, iron, and aluminum.

Europe

- Europe is experiencing a surge in demand for lightweight forged components, particularly in the aerospace sector, with companies like Airbus and Rolls-Royce collaborating with local forgers to develop advanced materials.

- The European Union's Green Deal is influencing the metal forging market by promoting sustainable practices, leading to increased investments in energy-efficient forging technologies and processes.

Asia Pacific

- The Asia-Pacific region is rapidly expanding its metal forging capabilities, with countries like China and India focusing on enhancing their manufacturing infrastructure to support the automotive and construction industries.

- Innovations in forging techniques, such as the adoption of 3D printing for mold creation, are being pioneered by companies like Tata Steel, which is expected to revolutionize the production processes in the region.

Latin America

- Latin America is seeing a rise in demand for forged products in the mining and energy sectors, with companies like Vale S.A. increasing their reliance on local forgers for high-quality components.

- Economic factors, such as fluctuating commodity prices, are influencing the metal forging market, prompting manufacturers to adapt their strategies to maintain competitiveness.

North America

- The North American metal forging market is witnessing significant advancements in automation and digitalization, with companies like Precision Castparts Corp. investing heavily in smart manufacturing technologies to enhance production efficiency.

- Regulatory changes aimed at reducing carbon emissions are prompting manufacturers to adopt greener forging processes, with initiatives from the U.S. Environmental Protection Agency encouraging the use of recycled materials in forging operations.

Middle East And Africa

- In the Middle East, the metal forging market is being driven by the growth of the oil and gas sector, with companies like Saudi Aramco investing in local forging capabilities to support their operations.

- Regulatory frameworks in the region are evolving, with governments promoting local manufacturing through initiatives that encourage foreign investment in forging technologies.

Did You Know?

“Did you know that the metal forging process can produce components that are up to 20% stronger than those made through traditional casting methods?” — American Society of Mechanical Engineers (ASME)

Segmental Market Size

The forging market is currently experiencing a steady growth, driven by the increasing demand from a number of industries, such as the automobile industry, the aeronautics industry, the construction industry, etc. It is driven by the growing need for lightweight and durable parts, as well as by the tightening of regulatory policies aimed at ensuring the quality and safety of products. The development of forging processes, such as precision forging and automation, also contributes to the growth of the market, by increasing the efficiency of the process and reducing the loss of material. The implementation of new forging technologies is currently at the stage of scaling up, with companies such as ThyssenKrupp and Alcoa being the leaders of the industry. The main applications of forging are the manufacture of gears, shafts and structural parts, especially in the automobile industry, where the performance and reliability of the products play an important role. Also, the growing interest in energy-efficient production and the implementation of the concept of sustainable development are pushing the market to grow, as companies try to minimize their impact on the environment. The development of new forging methods, such as the use of CAD and simulation, also contributes to the growth of the market, enabling more precise and efficient forging.

Future Outlook

The metal forging market is expected to experience a robust growth between 2024 and 2032, with a projected CAGR of 7.85%. The forging industry is largely driven by the rising demand from the key sectors, such as automobile, aerospace, and construction, where forged components are used to enhance the performance and lifespan of the products. In addition, as industries continue to focus on lightweight and high-strength materials, the use of advanced forging techniques, such as precision forging and hot forging, is expected to increase. Also, technological advancements and supportive government policies will continue to play a crucial role in shaping the future of the metal forging industry. For instance, the integration of automation and digitalization, such as the Industry 4.0, will boost the production efficiency and lower the production cost. Also, the implementation of the regulations pertaining to the reduction of the carbon footprint will encourage the use of eco-friendly forging practices. The forging industry is expected to witness a shift towards more sustainable materials and processes in line with the growing trend of adopting sustainable practices. The overall metal forging market is expected to experience a steady growth, driven by a combination of technological innovations, sectoral demands, and evolving regulations.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 89.43 Billion |

| Market Size Value In 2023 | USD 81.1 billion |

| Growth Rate | 6.34% (2022-2030) |

Metal Forging Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.