Research Methodology on Metal Forging Market

Introduction

Metal forging is the process of deforming metal parts through the application of compressive forces. This technique is used in the manufacture of metal components for both large and small projects. Metal forging is one of the oldest metalworking processes, and is used to make a variety of parts from weapons to car parts. The metal forging industry is a key part of the metalworking industry, as metal forging can produce components which are highly accurate, uniform, and resistant to corrosion.

Research Methodology

In order to complete comprehensive research on the Metal Forging Market, a range of research strategies have been employed. This report provides an overview of the current market for metal forging and its future outlook adopts the following research methodology:

Primary research is the most widely used research method in the present scenario. Primary research includes both qualitative and quantitative research methods. In-depth interviews are conducted with industry professionals, experts, and stakeholders. The interviews are conducted to obtain information regarding the dynamics and products offered in the global metal forging market. The interviews aim to assess the ongoing market trends and future growth potential of the metal forging industry.

Secondary research is conducted to obtain detailed information about the global metal forging industry. This includes reviewing both online and offline sources such as journals, past literature, databases, and other resources. Sources such as official websites of industry players, journals, and press releases are thoroughly studied and their content is assessed to extract data relevant to the research study. In order to gain an understanding of the market, Porter’s Five Force Model was used.

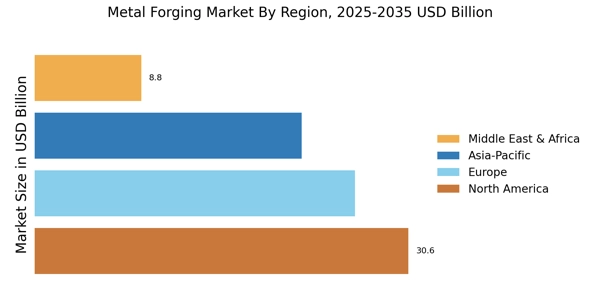

Market segmentation is done in order to identify the competitive landscape of the metal forging industry. The market is segmented based on application and geography. By application, the market is segmented into automotive, aerospace, construction, and others. By geography, the market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World.

A mix of bottom-up and top-down approaches is used to estimate and validate the market size and projected figures. The report includes the scope of the market, drivers, restraints, opportunities, and key industry trends. Macroeconomic indicators are used to analyze the overall market size. Several secondary sources are used to assess the impact of different factors on the metal forging industry. Finally, a comprehensive bottom-up and top-down approach is used to obtain the estimated and forecasted sizes of the market. In addition, the metal forging market is forecasted according to the market dynamics and segmentation.

The market size estimation and forecasting exercise require assumptions about different aspects of the global metal forging market. The assumptions made for market sizing and forecasting include the following:

The metal forging market is expected to remain stable in the near future.

The growth rate of the metal forging market is assumed to remain constant.

Regional trends of the metal forging market are assumed to remain the same throughout the forecast period.

Pricing of the different products offered in the metal forging market is assumed to remain stable.

Demand from key application segments is assumed to remain similar in the near future.

Demand and supply of raw materials are assumed to remain stable.

Conclusion

This report provides an overview of the current market for metal forging and its future outlook. Primary research and secondary research are used to estimate the size of the metal forging market and to forecast its future performance. The data collected and analyzed includes macroeconomic indicators, industry trends, demand and supply dynamics, applications, and regional trends. A comprehensive bottom-up and top-down approach is used to estimate and forecast the market size and projected figures. The report also includes the assumptions and limitations faced during the research exercise.