Mining Automation Market Overview:

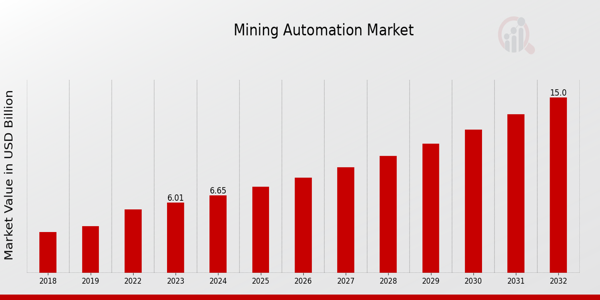

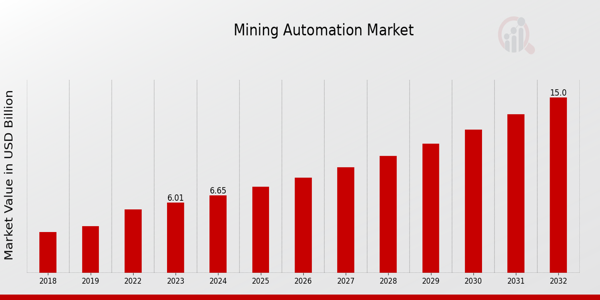

As per MRFR analysis, the Mining Automation Market Size was estimated at 5.57 (USD billion) in 2023. The Mining Automation Market is expected to grow from 6.05 (USD billion) in 2024 to 15 (USD billion) by 2035. The Mining Automation Market CAGR (growth rate) is expected to be around 8.6% during the forecast period (2025 - 2035).

Key Mining Automation Market Trends Highlighted

The necessity for increased safety and efficiency, as well as technological improvements, is driving a number of noteworthy trends in the worldwide mining automation market. The growing use of automated and robotic technologies in mining operations is a major market driver.

This change is mostly driven by the need to improve productivity, decrease human error, and simplify processes in an industry that frequently faces labor shortages and safety issues. Additionally, safety requirements are being emphasized by regulatory organizations throughout the world, which encourages businesses to invest in automation systems that guarantee adherence to these rules.

There are several opportunities in this sector, especially in emerging nations where mining activities are expanding. Businesses may improve their operational efficiency and environmental practices by implementing automation technology.

Mining companies may use automated solutions to enhance resource extraction while reducing their environmental impact, in line with global sustainability standards, as the demand for minerals continues to increase globally.

Artificial intelligence and machine learning are increasingly being included in mining automation systems, according to recent developments. Real-time data analysis made possible by this technology allows for predictive maintenance and optimal resource allocation in mines.

This tendency is further strengthened by the worldwide drive toward digital transformation, which pushes mining companies to use connected equipment that can exchange data across platforms with ease.

Because of this, the mining sector is progressively moving away from conventional techniques and toward smart mining technologies, which offer operators worldwide the potential for improved decision-making and more efficiency.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Mining Automation Market Drivers

Rising Demand for Operational Efficiency

The Mining Automation Market is experiencing significant growth driven by the increasing need for operational efficiency across mining operations. Automated systems reduce human intervention, thereby minimizing errors and enhancing productivity.

According to data from the International Council on Mining and Metals, automated mining processes can increase production efficiency by up to 50%. This shift towards automation is supported by major mining companies such as Rio Tinto and BHP, which have invested heavily in automated technologies like autonomous haul trucks and drills.

As the global demand for minerals and metals grows, particularly from developing economies, companies are increasingly adopting these technologies to stay competitive. The push for sustainability and cost-effectiveness, particularly in regions like Australia and Canada where labor costs are high, continues to escalate the adoption of automation in mining operations.

Government incentives and policies that support innovation in mining technologies will further reinforce this trend, significantly impacting the growth of the Mining Automation Market.

Technological Advancements in Mining Automation

Technological advancements are a key driver for the growth of the Mining Automation Market. Innovations such as artificial intelligence, machine learning, and the Internet of Things (IoT) are being integrated into mining operations, enhancing decision-making and operational productivity.

A report by the World Economic Forum indicates that automation and digitalization could add up to $10 trillion to the global economy by 2030. Companies such as Caterpillar and Komatsu are at the forefront, developing sophisticated mining equipment equipped with smart technologies.

With this ongoing evolution in technology, the mining sector is set to benefit from improved safety, reduced environmental impact, and overall increased efficiency, establishing a strong positive outlook for the Mining Automation Market.

Increasing Focus on Safety Regulations

The Mining Automation Market is being propelled by the increasing focus on safety regulations within the mining sector. Governments are implementing stricter regulations aimed at reducing accidents and enhancing the safety of mining operations.

According to the U.S. Mine Safety and Health Administration, despite the increased focus on safety regulations, mining still remains one of the most hazardous occupations. Automated systems play a crucial role in mitigating risks by reducing human presence in dangerous areas and improving monitoring capabilities.

Major mining firms such as Anglo American are integrating automation to comply with safety standards while ensuring operational continuity. This growing emphasis on health and safety not only helps in reducing fatalities but also encourages investment in automated systems, thereby boosting the Mining Automation Market.

Competitive Pressure and Market Dynamics

The Mining Automation Market is witnessing accelerated growth due to competitive pressures and market dynamics. As demand for raw materials continues to rise globally, companies are compelled to adopt innovative solutions that enhance efficiency and reduce costs.

The volatility in mineral prices further pushes mining companies to explore automation as a strategy to maintain profitability during downturns. Industry giants like Vale and Glencore are actively pursuing automation to streamline operations and gain a competitive edge.

This market dynamic creates a favorable environment for technology providers to innovate and deliver tailored automated solutions. The need for agility and responsiveness in a rapidly changing market landscape will significantly steer the growth trajectory of the Mining Automation Market.

Mining Automation Market Segment Insights:

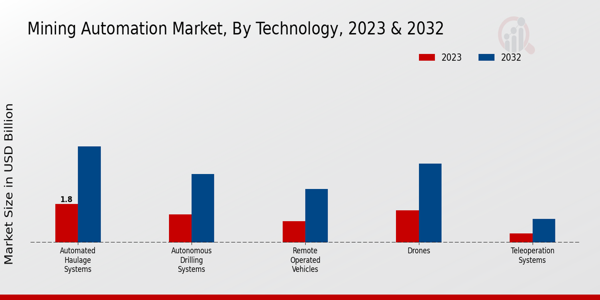

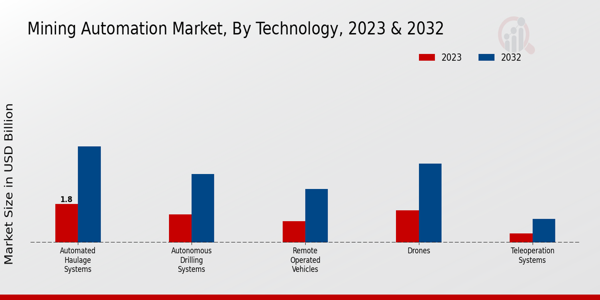

Mining Automation Market Technology Insights

The Technology segment of the Mining Automation Market was poised for significant growth. This segment encompasses various technological advancements that enhance operational efficiency, safety, and productivity in mining processes.

The Automated Haulage Systems, valued at 1.2 USD billion in 2024, experienced notable traction as they address key industry challenges, including labor shortages and operational risks through the automation of transport tasks.

Similarly, Remote Control Equipment contributed a substantial 1.1 USD billion in 2024, emphasizing the increasing demand for remote operation capabilities that minimize human presence in hazardous environments.

Drone-based monitoring, with a valuation of 1.0 USD billion in 2024, became essential for real-time surveying and surveillance, further enhancing the decision-making processes in mining operations.

Robotic Process Automation is projected to grow from 1.25 USD billion in 2024, offering significant optimizations in routine data management tasks, which ultimately enhance the overall productivity of mining activities by streamlining administrative operations.

Artificial Intelligence, accounting for 2.5 USD billion in 2024, dominated this Technology segment by enabling predictive analytics, improving efficiency, and driving safety innovations through advanced data-processing capabilities.

As the mining industry continues to evolve, these technologies play a crucial role in driving efficiency, enhancing safety, and reducing operational costs, thereby facilitating the accelerated adoption of automation solutions across the globe.

The trends within this segment indicate a robust shift toward intelligent, automated solutions that promise to reshape the future of mining operations while responding to the increasing demand for sustainability and efficiency within the sector.

The interplay of these technologies not only streamlines operations but also addresses the growing need for environmentally responsible practices in the mining industry.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Mining Automation Market Equipment Type Insights

The Mining Automation Market, focusing on the Equipment Type, with further growth leading into the next decade. The key components of this segment include Excavators, Drills, Loaders, Conveyors, and Haul Trucks, each playing a crucial role in enhancing operational efficiency and safety in mining operations.

Excavators are increasingly equipped with automation technologies to streamline digging processes, thus improving productivity. Drills benefit significantly from automation, allowing for precise and efficient rock fragmentation, which is essential in mineral extraction.

Loaders facilitate the movement of materials with reduced labor costs, enhancing overall efficiency. Conveyors are vital for material transportation within mining sites, minimizing the need for manual handling, while Haul Trucks, often seen as the backbone of mining logistics, dominate due to their ability to transport large volumes of mined materials swiftly.

This segment is actively supported by advancements in artificial intelligence and robotics, addressing challenges such as labor shortages and safety concerns while optimizing operational workflows. Overall, the Mining Automation Market statistics indicate a robust growth trajectory propelled by these equipment types, responding to the increasing demand for efficient and safe mining practices globally.

Mining Automation Market Application Insights

The Mining Automation Market is experiencing significant growth, particularly in the Application segment. This market is characterized by diverse segments, including Surface Mining, Underground Mining, Mineral Processing, Mine Maintenance, and Waste Management.

Surface Mining is pivotal due to its efficiency and lower operational costs, making it a preferred method in various regions. Underground Mining accounts for a considerable portion of operations, ensuring safety and resource extraction in challenging environments.

Mineral Processing plays a key role in maximizing the value of raw materials through innovative automation technologies. Mine Maintenance is crucial for minimizing operational downtime, while Waste Management is becoming increasingly significant due to stringent environmental regulations and sustainability considerations.

The demand for automation solutions in these areas is being driven by the need for improved safety standards, operational efficiency, and cost-effectiveness, reflecting the overall trend toward digitization and smart mining practices.

The Mining Automation Market statistics reveal ample opportunities for growth, addressing challenges such as labor shortages and the need for enhanced productivity in the mining industry.

Mining Automation Market End Use Insights

The Mining Automation Market is witnessing significant growth across its end-use segments, primarily driven by the increasing demand for efficiency and safety in mining operations. Within the End Use categories, Mining Companies are leveraging automation to optimize operations, leading to substantial cost reductions and improved safety metrics.

Contractors play a crucial role in facilitating the adoption of these technologies, allowing for flexible and scalable solutions tailored to various mining settings. Service Providers contribute by offering critical maintenance and support, ensuring that automation systems operate at peak performance, which enhances the reliability of mining operations.

Furthermore, Technology Providers are pivotal in advancing innovations that drive the development of autonomous equipment and systems. This dynamic interplay of various segments is crucial for the Mining Automation Market revenue, indicating a collective push towards a more automated future for the mining industry.

As the Mining Automation Market statistics suggest, this sector is well poised for considerable growth, with opportunities stemming from technological advancements and an increasing emphasis on sustainable mining practices.

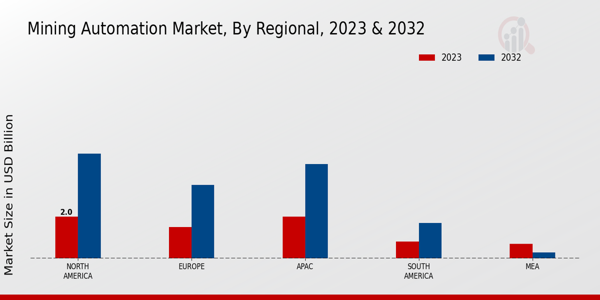

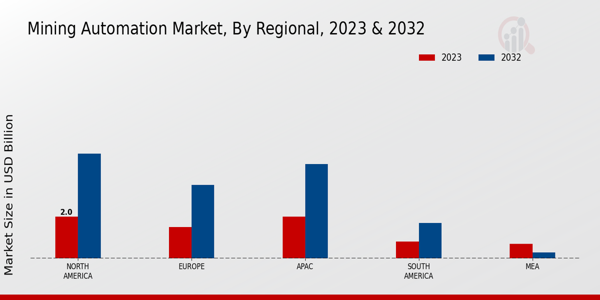

Mining Automation Market Regional Insights

The Mining Automation Market encompasses various regional segments, each contributing significantly to the overall market dynamics. In 2024, North America dominated this market with a valuation of 2.25 USD billion, expected to grow to 5.5 USD billion by 2035, largely driven by advancements in technology and a robust mining sector.

Europe followed with a valuation of 1.5 USD billion in 2024, projected to reach 3.8 USD billion by 2035, as companies increasingly adopt automation to improve efficiency. The Asia Pacific region, valued at 1.7 USD billion in 2024, is anticipated to grow to 4.1 USD billion by 2035, supported by the rapid industrialization and increasing demand for minerals.

South America and the Middle East and Africa also played essential roles, with valuations of 0.9 USD billion and 0.7 USD billion, respectively, in 2024, expected to increase to 2.3 USD billion and 1.3 USD billion by 2035. The mining sector across these regions evolved towards automation due to the need for safety improvements, cost reduction, and operational efficiency.

The Mining Automation Market segmentation illustrated the potential and unique challenges each region faces while exploring opportunities for growth, making them significant in the global mining landscape.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Mining Automation Market Key Players and Competitive Insights:

The Mining Automation Market is experiencing notable growth driven by advancements in technology and increasing demand for operational efficiency. As the mining industry faces pressures to enhance productivity and reduce costs, automation solutions are becoming essential.

Various organizations are investing in digital transformation and automation technology to optimize operations, improve safety standards, and manage resources effectively. Key players in this market are constantly innovating, incorporating artificial intelligence, machine learning, and robotics to create systems capable of automating various mining processes.

As competition intensifies, market players are focusing on strategic collaborations, partnerships, and acquisitions to strengthen their market positions and expand their technological capabilities.

In the context of the Mining Automation Market, FreeportMcMoran has built a strong reputation for its innovative approaches to integrating automation solutions within its operations. The company is recognized for its operational effectiveness and extensive experience in the mining sector, which allows it to leverage automation technologies that enhance productivity and safety.

FreeportMcMoran's commitment to sustainability and efficiency is reflected in its strategic initiatives, focusing on enhancing the automation of both surface and underground mining operations. This positions the company favorably in the automation landscape of the mining industry, allowing it to utilize advanced technologies to continually optimize its production processes and resource management.

Sandvik stands as a key player in the Mining Automation Market, known for its robust portfolio of automation solutions and mining equipment. The company offers a range of products and services, including autonomous drilling and loading systems, which significantly improve operational efficiency and safety for mining operations.

Sandvik has established a global presence, actively engaging in key markets across regions and continuously enhancing its technological capabilities through research and development. The company’s strengths lie in its innovative products, commitment to sustainability, and a strong focus on customer relationships.

Moreover, Sandvik has strategically pursued mergers and acquisitions to bolster its position in automation, expanding its capabilities and market reach. This dynamic approach enables Sandvik to remain competitive and well-positioned in the rapidly evolving Mining Automation Market, providing cutting-edge solutions that align with industry demands.

Key Companies in the Mining Automation Market Include:

-

FreeportMcMoRan

-

Sandvik

-

Caterpillar

-

Hexagon

-

ABB

-

Rockwell Automation

-

Rio Tinto

-

Terex

-

Thyssenkrupp

-

Eatons

-

BHP

-

Siemens

-

Atlas Copco

-

Komatsu

-

Emerson Electric

Mining Automation Industry Developments

Sandvik purchased Universal Field Robots in August 2024 in order to improve its robotic and autonomous drilling skills and incorporate them into its mining automation products.

An industry research conducted in July 2024 predicted that the autonomous mining truck market, which is driven by Komatsu and Caterpillar, would increase by USD 10 billion by 2030. Caterpillar is now working with Freeport-McMoran to convert Cat 793 haul trucks to operate autonomously at a large mine.

In 2024, Rio Tinto and Komatsu implemented autonomous drills and haul trucks in Australia's Pilbara area, advancing Pit-to-Port automation in one of the most automated heavy-iron ore mining zones globally.

By allowing completely autonomous mining activities and incorporating robots, digital twins, and fleet management systems throughout its worldwide operations, ABB enhanced its automation offering in 2025.

Mining Automation Market Segmentation Insights

-

Mining Automation Market Technology Outlook

Mining Automation Market Report Scope

|

Report Attribute/Metric

|

Details

|

|

Market Size 2023

|

5.57(USD billion)

|

|

Market Size 2024

|

6.05(USD billion)

|

|

Market Size 2035

|

15.0(USD billion)

|

|

Compound Annual Growth Rate (CAGR)

|

8.6% (2025 - 2035)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025 - 2035

|

|

Historical Data

|

2019 - 2024

|

|

Market Forecast Units

|

USD billion

|

|

Key Companies Profiled

|

FreeportMcMoran, Sandvik, Caterpillar, Hexagon, ABB, Rockwell Automation, Rio Tinto, Terex, Thyssenkrupp, Eaton, BHP, Siemens, Atlas Copco, Komatsu, Emerson Electric

|

|

Segments Covered

|

Technology, Equipment Type, Application, End Use, Regional

|

|

Key Market Opportunities

|

Increased focus on safety protocols, Demand for operational efficiency, Growth of AI and robotics, Expansion of remote monitoring solutions, Adoption of IoT for real-time data

|

|

Key Market Dynamics

|

Technological advancements, Increased operational efficiency, Safety and risk management, Labor cost reduction, and Environmental regulations compliance

|

|

Countries Covered

|

North America, Europe, APAC, South America, MEA

|

Mining Automation Market Highlights:

Frequently Asked Questions (FAQ):

The Global Mining Automation Market was valued at 6.05 USD billion in 2024.

By 2035, the Global Mining Automation Market is expected to reach a value of 15.0 USD billion.

The expected CAGR for the Global Mining Automation Market from 2025 to 2035 is 8.6%.

North America is projected to have the largest market size, valued at 5.5 USD billion by 2035.

Automated Haulage Systems were valued at 1.2 USD billion in 2024.

Major players in the market include FreeportMcMoran, Sandvik, Caterpillar, Hexagon, and ABB.

Drone-based monitoring is projected to be valued at 2.5 USD billion by 2035.

The anticipated market size for South America is 2.3 USD billion by 2035.

The Remote Control Equipment segment is expected to grow to 2.8 USD billion by 2035.

Challenges may include technological integration and regulatory hurdles influencing the market's growth trajectory.