- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

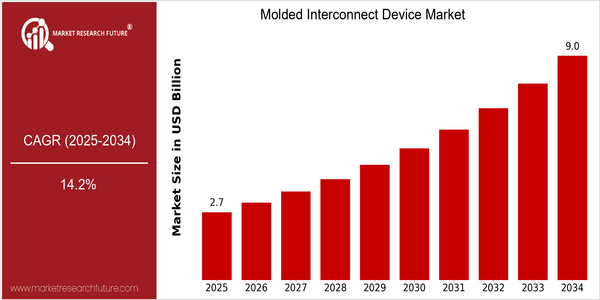

| Year | Value |

|---|---|

| 2025 | USD 2.72 Billion |

| 2034 | USD 8.99 Billion |

| CAGR (2025-2034) | 14.2 % |

Note – Market size depicts the revenue generated over the financial year

The market for molded interconnection devices (MIDs) is growing rapidly. The MID market is expected to reach $ 2.8 billion in 2025, and is projected to reach $ 8.9 billion by 2034. This growth translates into a high CAGR of 14.2% over the forecast period. This growth is driven by the growing demand for miniaturized electronic components and the increasing trend of integrating multiple functions into a single device. Further technological developments, such as 3D printing and injection molding, are further expanding the capabilities and applications of MIDs in various sectors, such as automobiles, consumer goods and medical devices. These developments are being seized by MID suppliers such as Molex, TE Connectivity and Amphenol to launch new products. The recent development of next-generation MIDs for automobiles, for example, reflects the industry's commitment to utilizing technology to improve performance and efficiency.

Regional Market Size

Regional Deep Dive

The molded interconnection device (MID) market is experiencing significant growth in various regions. It is driven by the advancement of miniaturization and the growing demand for compact electronics. The North American MID market is characterized by a strong presence of leading players and a strong focus on innovation, particularly in the automotive and consumer electronics sectors. Europe, on the other hand, is experiencing strong growth in demand for molded interconnection devices. This is mainly due to stricter waste disposal regulations and the push for sustainable production. The Asia-Pacific region is becoming the hub for molded interconnection devices. The Middle East and Africa are slowly embracing the technology across industries. Latin America is also emerging as a potential market, mainly driven by the growing investments in electronics and telecommunications.

Europe

- Europe is witnessing a rise in MID applications in the medical device sector, driven by innovations from companies like Siemens and Philips, which are focusing on compact and efficient designs.

- The European Union's stringent regulations on electronic waste and recycling are pushing manufacturers to adopt MIDs, as they facilitate easier disassembly and recycling of electronic products.

Asia Pacific

- Asia-Pacific is home to major electronics manufacturers like Samsung and Sony, who are leveraging MIDs to enhance product functionality while minimizing space, particularly in smartphones and wearables.

- The region is also seeing significant investments in research and development for MID technologies, with government initiatives in countries like Japan and South Korea aimed at fostering innovation in electronics.

Latin America

- Latin America is experiencing a surge in MID applications in consumer electronics, with local companies beginning to explore these technologies to enhance product offerings.

- Government initiatives aimed at boosting the electronics manufacturing sector in countries like Brazil and Mexico are expected to drive the adoption of MIDs in the region.

North America

- The automotive industry in North America is increasingly adopting MIDs for their ability to reduce weight and improve design flexibility, with companies like Tesla and Ford leading the charge in integrating these devices into their vehicles.

- Recent regulatory changes aimed at reducing electronic waste have prompted manufacturers to explore MIDs as a sustainable alternative, with organizations such as the Environmental Protection Agency (EPA) promoting eco-friendly practices.

Middle East And Africa

- The Middle East is gradually adopting MIDs in the telecommunications sector, with companies like Etisalat exploring their use in network infrastructure to improve efficiency.

- In Africa, the growing demand for affordable electronics is leading to increased interest in MIDs, as they offer a cost-effective solution for manufacturers looking to reduce production costs.

Did You Know?

“Molded Interconnect Devices can integrate multiple functions into a single component, potentially reducing the number of parts in an electronic assembly by up to 50%.” — Industry reports and market analysis studies

Segmental Market Size

The field of molded interconnection devices plays a crucial role in the field of electrical and electronic products, especially in the field of miniaturization and the integration of components. The field of molded interconnection devices is currently experiencing a boom, resulting from the growing demand for compact and efficient electronic devices. The demand for lighter designs in the field of consumer electronics and in the field of automobiles, as well as the increasing complexity of the manufacturing processes, have contributed to this growth. At present, the field of molded interconnection devices is in the process of being rolled out, and automobile applications are leading the way, especially in the integration of sensors and the control units. The field of molded interconnection devices is also gaining ground in the field of mobile phones and medical devices, where the space and weight savings are particularly critical. The growing trend towards sustainability and the rise of electric vehicles will further accelerate the growth in this field, as the trend towards resource conservation and energy efficiency increases. Also, the technological developments, such as 3D printing and the injection molding of complex parts, will contribute to the development of molded interconnection devices, as they will allow for the design of new shapes and shorter production cycles.

Future Outlook

During the period 2025 to 2034, the MID market is expected to grow from $2.72 billion to $8.9 billion, at a strong CAGR of 14.2%. The demand for miniaturized electronics components is growing rapidly in many industries, including automobiles, consumer electronics, and medical devices. In the course of this process, manufacturers are attempting to optimize space and enhance functionality. The penetration of MIDs in these areas is expected to increase, and in 2034, the percentage penetration in the automobile industry may reach 30%, and in the consumer industry, 25%. The key technological developments, such as the integration of advanced materials and processes in MID manufacturing, will continue to drive the growth of the MID market. The advances in 3D printing and injection molding are enabling MIDs to be manufactured in a more complex fashion, at lower costs, thus making MIDs more affordable and accessible for a wider range of applications. Also, the policies promoting sustainable manufacturing will encourage the adoption of MIDs, which produce less waste and use less energy than traditional assembly methods. The emergence of the Internet of Things (IoT) and the proliferation of smart devices will also play a key role in shaping the future landscape of the MID market.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 14.20% (2024-2032) |

Molded Interconnect Device Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.