- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

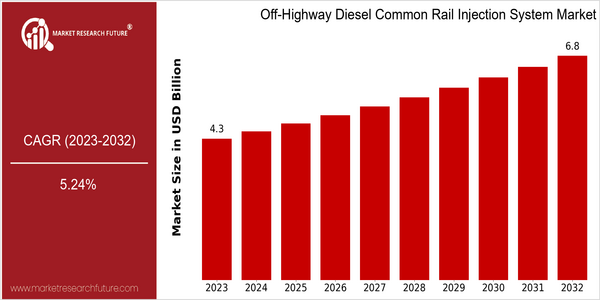

| Year | Value |

|---|---|

| 2023 | USD 4.29 Billion |

| 2032 | USD 6.8 Billion |

| CAGR (2024-2032) | 5.24 % |

Note – Market size depicts the revenue generated over the financial year

OFF-HIGHWAY DIESEL COMMON RAIL INJECTION SYSTEM MARKET VALUE IS ESTIMATED TO REACH 6.8 BILLION DOLLARS IN 2032 AT A CAGR OF 5.24% DURING THE PERIOD 2024 TO 2032. This growth trajectory is driven by the growing demand for fuel efficiency and reduced emissions in off-highway applications such as construction, agriculture, and mining. As regulatory requirements become more stringent, manufacturers are forced to develop new products to stay competitive. Injection technology has improved with the integration of electronic control systems and the development of fuel atomization techniques. These developments have enhanced the performance and efficiency of engines. The increasing uptake of off-highway vehicles in emerging economies is also expected to drive the market. Competition is also expected to intensify as companies such as Robert Bosch, Denso, and Delphi Technology focus on launching new products and establishing strategic alliances. These strategies are aimed at not only meeting the changing needs of the market but also retaining a competitive advantage in a rapidly changing environment.

Regional Market Size

Regional Deep Dive

The diesel injection system for off-highway applications is growing across the world, driven by the increasing demand for fuel-efficient and high-performance engines in off-highway applications. The market is also influenced by technological developments, stringent emission regulations, and the increasing use of advanced agricultural and construction machinery. Each region has its own characteristics, with varying degrees of industrialization, regulatory frameworks, and economic conditions that shape the market.

Europe

- European tractors have been at the forefront of adopting advanced common-rail injection systems, largely as a result of the strict European Union emissions standards that limit the emissions of nitrogen oxides and particulate matter from such machines. Consequently, companies such as Delphi Technologies and Denso are actively developing next-generation injection systems.

- The European market is also seeing increased investment in research and development for alternative fuels and hybrid systems, which is expected to reshape the off-highway diesel landscape and drive innovation in common rail technologies.

Asia Pacific

- The rapid industrialization and urbanization in the Asia-Pacific region, which is currently experiencing a sharp increase in off-road vehicles, is mainly a result of the increasing demand for construction machinery and agricultural machinery. The major manufacturers, such as Yanmar and Isuzu, are increasing their production capacity to meet this growing demand.

- In the next decade, a number of governments in Asia, particularly China and India, will be pursuing modernization policies in agriculture and in building and road construction, which will increase the use of common-rail injection systems, thus contributing to the overall growth of the market.

Latin America

- The growing productivity of agriculture and the expansion of roads are gradually pushing Latin America towards more efficient diesel engines. Major manufacturers like Volkswagen and Scania are investing in local production to meet this demand.

- Regulatory changes aimed at reducing emissions in countries like Brazil and Argentina are prompting manufacturers to innovate and adapt their technologies, which is expected to enhance the competitiveness of off-highway diesel systems in the region.

North America

- In the North American market, the introduction of common rail injection is booming, particularly in the agricultural sector, and the demand for greater fuel efficiency and lower emissions. The leading companies are Cummins Inc. and Bosch, who are concentrating on developing systems that comply with the strict EPA regulations.

- Recent regulatory changes, such as the introduction of the Clean Air Act amendments, are pushing manufacturers to invest in cleaner technologies, which is expected to accelerate the transition towards more efficient off-highway diesel engines.

Middle East And Africa

- The off-highway diesel injection systems market is driven by the mining and construction industries in the United Arab Emirates and South Africa. Companies such as Caterpillar and Komatsu are investing in new technology to improve the performance and efficiency of their engines.

- The region's unique economic factors, including fluctuating oil prices and a focus on sustainable development, are influencing the adoption of cleaner diesel technologies, which is expected to create new opportunities for market players.

Did You Know?

“Did you know that diesel engines equipped with common rail injection systems can achieve fuel efficiency improvements of up to 15% compared to traditional fuel injection systems?” — International Council on Clean Transportation (ICCT)

Segmental Market Size

Off-Highway Common-Rail injection systems play a major role in improving fuel economy and reducing emissions in heavy vehicles and machinery. This market is currently growing as a result of the growing demand for engines that are both more economical and cleaner-burning in the construction, agriculture, and mining industries. The demand is driven by stricter emissions regulations, such as the EPA Tier 4 standard in the United States, as well as the need for higher performance in these applications. At the present time, the use of common-rail injection systems has reached a point where Caterpillar and John Deere have made them standard on their equipment. In the main, the system is used in tractors and excavators, where improved fuel economy leads to lower operating costs. The trend toward greater concern for the environment and stricter regulations on emissions have accelerated the growth of this market. Also, advances in injection technology, such as the use of piezo-electronic injectors, are making it possible to design engines that are more economical and responsive to changing loads.

Future Outlook

Off-highway diesel injection systems for off-road vehicles are expected to experience significant growth from 2023 to 2032, with a CAGR of 5.24% from 2023 to 2032. This growth is mainly driven by the increasing demand for fuel-efficient and low-emission engines in off-road applications, which is mainly driven by the increasingly stringent environment regulations and the general trend of sustainable development. The number of common rail injection systems is expected to increase as the performance and fuel efficiency of off-road vehicles and equipment is expected to improve. The key technological advances in fuel atomization and the integration of ECUs are expected to drive the market further. As for hybrid and electric off-road vehicles, they may create new opportunities for common rail systems, as manufacturers seek to optimize performance in the transitional energy environment. Also, the adoption of telematics and preventive maintenance in off-road equipment will have a significant impact on the market, as operators can increase efficiency and reduce costs. In summary, the off-highway common rail injection system market will develop rapidly, driven by innovation and commitment to sustainable development.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | (2023-2032 |

Off Highway Diesel Common Rail Injection System Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.