Polycaprolactone Size

Polycaprolactone Market Growth Projections and Opportunities

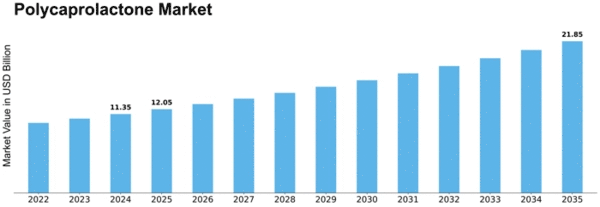

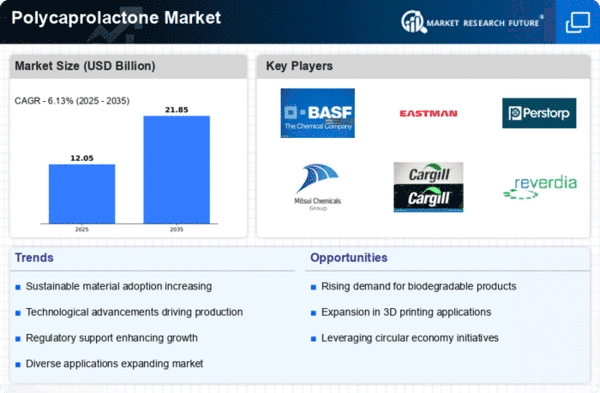

The Polycaprolactone (PCL) market is influenced by many factors that combine to shape its dynamics and trajectory. The rising demand for biodegradable polymers in different sectors is among the primary factors shaping the market. As the focus on the environment increases, there is an inclination toward sustainable materials, making PCL, with its biodegradability, one of the best alternatives. The global polycaprolactone market was valued at USD 1 billion in 2028 and will expand at a CAGR of more than 11.6% during this forecast period. In addition, the versatility of PCL contributes significantly to its market growth. Being able to blend with other materials and improve their properties while remaining biodegradable makes this polymer highly demanded across various industries. This adaptability has brought about increased research and development activities aimed at exploring new applications for PCL, thus expanding its market reach. Global economic factors also play a crucial role in shaping the Polycaprolactone market. Economic fluctuations, trade policies, and regional economic conditions impact the production and consumption patterns of PCL. For instance, when there are robust construction activities within a given area, demand for adhesives and sealants may rise, while it might dip when downturns occur in any case due to that factor, too. Technological advancements represent another key factor influencing the PCL market. Ongoing innovations in polymer chemistry and manufacturing processes have led to improved products made from PCL that have better performance characteristics. This further stimulates market expansion since companies look for more effective advanced materials matching their changing demands. The current research developing around PCL contributes toward a redefinition of its purpose. Regulatory frameworks also significantly shape the Polycaprolactone market. As governments globally introduce strict rules meant to curb environmental pollution, the demand for eco-friendly materials like PCL goes up. Compliance with environmental standards becomes a crucial factor for industries, driving them to adopt PCL-based solutions in their products and processes. Market competition and dynamics among key players add another layer to the market factors influencing PCL. The presence of major manufacturers, their production capacities, and strategic alliances impact the overall market structure. Price fluctuations, supply chain disruptions, and market consolidation events can all influence the supply and demand balance in the PCL market. Consumer preferences and awareness contribute to the market dynamics of polycaprolactone as well. As consumers become more conscious of the environmental impact of their choices, there is a growing demand for products made from sustainable materials, including those incorporating PCL.

Leave a Comment