Top Industry Leaders in the Polycarbonate Panels Market

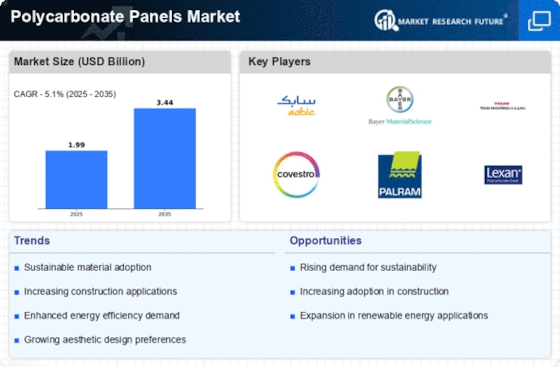

The global polycarbonate panels market is a dynamic and constantly evolving space, driven by a confluence of factors like growing demand for lightweight, durable materials, rising urbanization, and increasing awareness of sustainability. Amidst this vibrant backdrop, a fierce competition rages between key players, each vying for a larger slice of the pie. Let's delve into the intricate tapestry of this market, exploring the strategies adopted, factors influencing market share, industry news, and recent developments.

The global polycarbonate panels market is a dynamic and constantly evolving space, driven by a confluence of factors like growing demand for lightweight, durable materials, rising urbanization, and increasing awareness of sustainability. Amidst this vibrant backdrop, a fierce competition rages between key players, each vying for a larger slice of the pie. Let's delve into the intricate tapestry of this market, exploring the strategies adopted, factors influencing market share, industry news, and recent developments.

List of Strategies Adopted:

-

Product Differentiation: Players are constantly innovating, developing new grades with enhanced properties like flame retardancy, UV protection, and improved temperature resistance. Covestro, for instance, introduced Makrofol FR, a polycarbonate sheet with superior fire safety for building and construction applications. -

Regional Expansion: Expanding into emerging markets with high growth potential like India, China, and Southeast Asia is a crucial strategy. SABIC, a Saudi Arabian giant, has invested heavily in expanding its production capacity in China to cater to the region's booming demand. -

Vertical Integration: Integrating upstream and downstream operations helps companies optimize costs and gain control over the supply chain. Trinseo, a US-based player, acquired Polymerland, a leading European distributor, strengthening its distribution network and customer reach. -

Sustainability Focus: The growing focus on environmental concerns has led to the development of bio-based and recycled polycarbonate panels. Palram Industries, an Israeli company, offers a range of eco-friendly panels made from recycled materials. -

Strategic Partnerships and Collaborations: Collaborating with research institutions, universities, and other industry players fosters innovation and accelerates product development. Covestro partnered with the Fraunhofer Institute for Chemical Technology to develop lightweight polycarbonate sheets for automotive applications.

Factors Influencing Market Share:

-

Brand Reputation and Quality: Established players with a reputation for high-quality products like Bayer, Mitsubishi Chemical, and Teijin hold a significant market share. -

Cost-Competitiveness: Efficient production processes, economies of scale, and access to raw materials at competitive prices play a crucial role in determining market share. -

Distribution Network and Customer Service: A robust distribution network and strong customer service capabilities ensure product availability and customer satisfaction, leading to market share growth. -

Technological Innovation: Continuous investment in R&D and the development of new technologies like co-extrusion and multi-layer sheets help companies stay ahead of the curve and gain market share. -

Government Policies and Regulations: Government policies related to environmental regulations, building codes, and subsidies can significantly impact the demand for polycarbonate panels and influence market share.

Key CompaniesIn The Polycarbonate Panels Market include

- SABIC (Saudi Arabia)

- Covestro AG (Germany)

- Trinseo (US)

- Palram Industries Ltd. (Israel)

- UgPlast Inc (US)

- PlazitPolygal (US)

- Gallina USA (US)

- Stabilit Suisse SA (Europe)

- Brett Martin Plastic Sheets (UK)

- DS Smith (UK). MITSUBISHI GAS CHEMICAL COMPANY

- Evonik Industries AG (Germany)

- Excelite (China)

- 3A Composites GmbH (Germany)

Recent Developments:

-

October 2023: SABIC announced plans to invest USD 100 million in expanding its polycarbonate sheet production capacity in China. -

November 2023: Covestro unveiled a new polycarbonate sheet with self-healing properties, targeting applications in the automotive and aerospace industries. -

December 2023: Trinseo entered into a joint venture with a leading Chinese company to produce and distribute polycarbonate panels in China. -

January 2024: The European Union announced stricter regulations on fire safety standards for building materials, benefiting flame-retardant polycarbonate panels. -

February 2024: A major fire incident at a polycarbonate panel manufacturing facility in India raises concerns about safety standards and quality control.