Top Industry Leaders in the Polylactic Acid Market

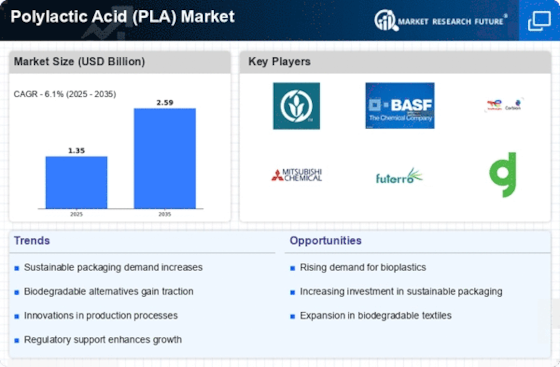

Polylactic acid (PLA), a biodegradable and bio-based plastic, is experiencing a surge in demand, driven by increasing environmental awareness and stricter regulations on traditional plastics. This shift has ignited a fierce competitive landscape within the PLA market, with established players jostling for dominance and new entrants seeking to carve their niche.

Polylactic acid (PLA), a biodegradable and bio-based plastic, is experiencing a surge in demand, driven by increasing environmental awareness and stricter regulations on traditional plastics. This shift has ignited a fierce competitive landscape within the PLA market, with established players jostling for dominance and new entrants seeking to carve their niche.

Strategies Adopting a Sprout:

-

Technology and Innovation: Leading players like NatureWorks LLC and TotalEnergies Corbion are investing heavily in R&D to refine PLA production processes, improve properties like heat resistance, and explore novel applications. BASF SE, for instance, recently unveiled a new PLA filament specifically designed for 3D printing. -

Vertical Integration: Companies like Danimer Scientific are looking beyond just PLA production, venturing into downstream segments like compostable foodserviceware and bio-based chemicals. This vertical integration offers greater control over the supply chain and cost advantage. -

Strategic Partnerships: Collaboration is key. Evonik Industries has partnered with Mitsubishi Chemical Corporation to manufacture and market PLA in Asia, while COFCO is collaborating with Toray Industries to expand PLA production in China. Such partnerships leverage geographic strengths and technical expertise. -

Sustainability Focus: The environmental narrative is paramount. Companies are highlighting their commitment to eco-friendly practices, using renewable feedstocks, and implementing closed-loop recycling systems. This resonates with environmentally conscious consumers and attracts brand-conscious businesses.

Factors Fertilizing Market Share:

-

Production Capacity: Companies with robust production capabilities and expanding facilities, like NatureWorks' Nebraska expansion, have an edge in meeting the surging demand. -

Cost Competitiveness: Bringing down the price of PLA compared to traditional plastics is crucial for wider adoption. Technological advancements and economies of scale play a vital role here. -

Regional Focus: Asia Pacific, particularly China, is a booming market for PLA. Companies with strong regional presence and partnerships stand to benefit. -

Product Diversification: Offering a diverse range of PLA grades and formulations catering to specific applications like 3D printing, textiles, and medical devices broadens reach and attracts targeted customer segments.

Key Companies in the Polylactic Acid (PLA) market includes

-

BASF SE

-

The DOW Chemical Company

-

Corbion

-

TEIJIN LIMITED.

-

NatureWorks LLC

-

Synbra Technology

-

Galactic

-

Sulzer Ltd

-

Hitachi, Ltd.

-

Musashino Chemical Laboratory, Ltd among others

Recent Developments:

November 2021: Total Corbion PLA in partnership with Danimer Scientific, Inc, announced that they have entered into a long-term collaborative arrangement for the supply of Luminy PLA, a biobased polymer used to manufacture compostable products.

November 2020: The development of China’s first fully integrated sugar-to-PLA (polylactic acid) was supported by Sulzer Chemtech for the plant located in Bengbu, Anhui Province.