- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

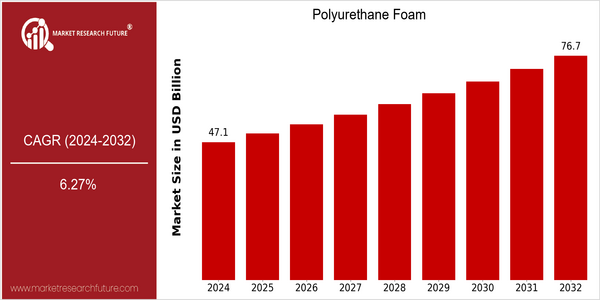

| Year | Value |

|---|---|

| 2024 | USD 47.11 Billion |

| 2032 | USD 76.65 Billion |

| CAGR (2024-2032) | 6.27 % |

Note – Market size depicts the revenue generated over the financial year

The global polyurethane foam market is poised for significant growth, with a current market size of USD 47.11 billion in 2024, projected to reach USD 76.65 billion by 2032. This growth trajectory reflects a robust compound annual growth rate (CAGR) of 6.27% over the forecast period from 2024 to 2032. The increasing demand for polyurethane foam across various applications, including automotive, construction, and furniture, is a key driver of this expansion. As industries continue to prioritize lightweight materials that offer superior insulation and cushioning properties, polyurethane foam is becoming increasingly integral to product design and manufacturing processes. Technological advancements, such as the development of bio-based polyurethane foams and innovations in manufacturing processes, are further propelling market growth. Companies like BASF, Huntsman Corporation, and Dow Inc. are at the forefront of these innovations, investing in sustainable practices and expanding their product portfolios to meet evolving consumer demands. Strategic initiatives, including partnerships and collaborations aimed at enhancing product performance and sustainability, are also shaping the competitive landscape. As the market evolves, these factors will play a crucial role in driving the adoption of polyurethane foam across diverse sectors.

Regional Market Size

Regional Deep Dive

The Polyurethane Foam Market is experiencing dynamic growth across various regions, driven by increasing demand in sectors such as automotive, construction, and furniture. Each region exhibits unique characteristics influenced by local economic conditions, regulatory frameworks, and cultural preferences. North America is characterized by a strong manufacturing base and innovation in sustainable materials, while Europe focuses on stringent environmental regulations and high-performance applications. The Asia-Pacific region is witnessing rapid industrialization and urbanization, leading to heightened demand for versatile foam solutions. Meanwhile, the Middle East and Africa are gradually adopting polyurethane technologies, and Latin America is seeing growth fueled by rising disposable incomes and construction activities.

Europe

- In Europe, the market is heavily impacted by the European Union's Green Deal, which aims to make the region climate-neutral by 2050, prompting manufacturers to focus on bio-based and recyclable polyurethane foams.

- Key players like BASF and Covestro are leading the charge in developing innovative foam solutions that meet stringent EU regulations, thus driving advancements in product performance and environmental compliance.

Asia Pacific

- The Asia-Pacific region is witnessing a surge in demand for polyurethane foams due to rapid urbanization and infrastructure development, with countries like China and India investing heavily in construction and automotive sectors.

- Innovations in manufacturing processes, such as the adoption of water-blown technology by companies like Wanhua Chemical Group, are enhancing the production of eco-friendly polyurethane foams, aligning with the region's growing environmental consciousness.

Latin America

- Latin America is experiencing growth in the polyurethane foam market driven by rising disposable incomes and a burgeoning middle class, particularly in Brazil and Mexico, which are seeing increased demand for consumer goods and furniture.

- The region is also witnessing a shift towards sustainable practices, with companies like Grupo Bimbo investing in eco-friendly packaging solutions that utilize polyurethane foams, reflecting a broader trend towards sustainability in consumer products.

North America

- The North American polyurethane foam market is significantly influenced by the automotive industry's shift towards lightweight materials, with companies like Ford and General Motors investing in polyurethane solutions to enhance fuel efficiency.

- Recent regulatory changes, such as the U.S. Environmental Protection Agency's (EPA) initiatives to reduce volatile organic compounds (VOCs), are pushing manufacturers to innovate and develop low-emission polyurethane foams, thereby enhancing sustainability in the market.

Middle East And Africa

- In the Middle East and Africa, the polyurethane foam market is being shaped by increasing investments in the construction sector, particularly in countries like the UAE and Saudi Arabia, where mega-projects are underway.

- Local companies are collaborating with international firms to enhance their technological capabilities, as seen in the partnership between Saudi-based Al-Jazeera Foam Products and global suppliers to improve product quality and sustainability.

Did You Know?

“Did you know that polyurethane foams can be engineered to be both flexible and rigid, making them suitable for a wide range of applications from mattresses to insulation materials?” — Polyurethane Foam Association

Segmental Market Size

The flexible polyurethane foam segment plays a crucial role in the overall polyurethane foam market, currently experiencing stable growth due to its diverse applications in various industries. Key drivers of demand include the rising consumer preference for comfort in furniture and bedding, alongside increasing automotive production, which necessitates lightweight and durable materials. Additionally, regulatory policies promoting energy efficiency in building materials further bolster this segment's relevance. Currently, the adoption of flexible polyurethane foam is in a mature stage, with companies like BASF and Dow leading in innovation and production. Notable applications include cushioning in mattresses, automotive seating, and insulation in construction. Trends such as the push for sustainable materials are catalyzing growth, with manufacturers exploring bio-based polyols and recycling initiatives. Technologies like advanced foam formulation and manufacturing processes are shaping the segment's evolution, enabling enhanced performance and environmental compliance.

Future Outlook

The polyurethane foam market is poised for significant growth from 2024 to 2032, with a projected market value increase from $47.11 billion to $76.65 billion, reflecting a robust compound annual growth rate (CAGR) of 6.27%. This growth trajectory is underpinned by rising demand across various sectors, including automotive, construction, and furniture, where polyurethane foam is increasingly favored for its lightweight, durable, and versatile properties. As industries continue to prioritize energy efficiency and sustainability, the adoption of polyurethane foam in insulation applications is expected to surge, driven by stringent building codes and regulations aimed at reducing carbon footprints. Key technological advancements, such as the development of bio-based polyurethane foams and innovations in manufacturing processes, are anticipated to further enhance market penetration. The shift towards environmentally friendly materials is gaining momentum, with consumers and manufacturers alike seeking sustainable alternatives. Additionally, the expansion of the e-commerce sector is likely to boost demand for packaging solutions that utilize polyurethane foam, as companies strive to ensure product safety during transit. Overall, the polyurethane foam market is set to experience dynamic growth, supported by evolving consumer preferences and regulatory frameworks that favor sustainable practices.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 43.95 billion |

| Growth Rate | 6.27% (2024-2032) |

Polyurethane Foam Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.