- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

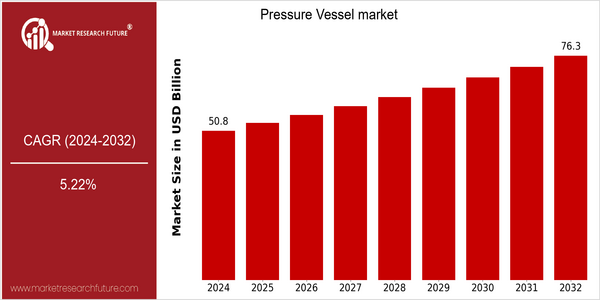

| Year | Value |

|---|---|

| 2024 | USD 50.77 Billion |

| 2032 | USD 76.3 Billion |

| CAGR (2024-2032) | 5.22 % |

Note – Market size depicts the revenue generated over the financial year

The pressure vessel market is growing steadily and is expected to reach USD 77.9 billion by 2032. This is equivalent to a CAGR of 5.22% during the forecast period. The main reason for this growth is the increasing demand for pressure vessels in the oil and gas, chemical and energy industries. The pressure vessel market is expected to grow due to the increasing need for safe and efficient containment solutions as industries continue to develop. The development of high-strength materials and the introduction of new manufacturing methods will also help the market grow. These innovations will improve the performance and safety of pressure vessels and will increase their attractiveness to end users. Meanwhile, the market is being actively developed by companies such as Emerson Electric Co., Mitsubishi Heavy Industries, and Siemens AG. The development of smart technology and the integration of smart technology into pressure vessels are expected to drive the market.

Regional Market Size

Regional Deep Dive

In various parts of the world, the market for pressure vessels is growing rapidly. This is due to the increasing industrialization, the stricter safety regulations, and the increasing demand for energy. North America is characterized by a high degree of technical development and innovation, especially in the oil and gas industry. In Europe, a tendency towards sustainable development is noticeable, which has an influence on the design and the materials used in pressure vessels. In Asia-Pacific, the construction and manufacturing industries are growing rapidly. The Middle East and Africa are growing due to the exploration of oil and gas. Latin America, although growing less quickly, is adopting new production methods for pressure vessels, influenced by foreign investments and the development of the region’s infrastructure.

Europe

- The European Union's Green Deal is pushing for stricter emissions regulations, prompting manufacturers to develop pressure vessels that utilize eco-friendly materials and technologies.

- Notable projects, such as the North Sea Wind Power Hub, are increasing the demand for high-capacity pressure vessels designed for renewable energy applications, showcasing a shift towards sustainable energy solutions.

Asia Pacific

- China's Belt and Road Initiative is leading to increased infrastructure projects, significantly boosting the demand for pressure vessels in construction and energy sectors.

- Innovations in manufacturing processes, such as additive manufacturing, are being adopted by companies like Mitsubishi Heavy Industries, enhancing the customization and efficiency of pressure vessel production.

Latin America

- Brazil's recent investments in offshore oil exploration are creating opportunities for pressure vessel manufacturers, as the country seeks to enhance its energy production capabilities.

- Regulatory changes in Argentina aimed at improving industrial safety standards are prompting local manufacturers to upgrade their pressure vessel technologies to meet new compliance requirements.

North America

- The U.S. Department of Energy has introduced new regulations aimed at enhancing the safety and efficiency of pressure vessels used in energy production, which is expected to drive innovation and compliance costs in the sector.

- Companies like Emerson and Honeywell are investing in smart pressure vessel technologies, integrating IoT solutions to improve monitoring and maintenance, thereby enhancing operational efficiency.

Middle East And Africa

- The UAE's commitment to diversifying its economy away from oil dependency is driving investments in petrochemical and renewable energy sectors, increasing the demand for advanced pressure vessels.

- Saudi Aramco's ongoing projects in oil and gas exploration are leading to a surge in demand for high-performance pressure vessels, emphasizing the need for compliance with international safety standards.

Did You Know?

“Pressure vessels are designed to operate at pressures significantly higher than atmospheric pressure, with some vessels capable of withstanding pressures exceeding 10,000 psi.” — American Society of Mechanical Engineers (ASME)

Segmental Market Size

The pressure vessel market is presently characterized by stability. Demand is currently being met by the oil and gas, chemical and electrical industries. The main driving forces behind this demand are the ever more stringent safety and environment regulations and technological advances that are improving the efficiency and reliability of pressure vessel design and manufacture. Companies like Siemens and GE are at the forefront of these technological advances. These pressure vessels are already being used in a wide variety of applications. There is particular demand for the transport and storage of Liquefied Natural Gas in the Middle East and North America, where the natural gas industry is expanding. The development of sustainable energy and the trend towards the use of renewable energy sources are also driving the market, as industry is compelled to reduce its emissions and improve its energy efficiency. The use of new materials and digitally controlled monitoring systems are influencing the development of this market, and are enabling pressure vessels to meet modern operational demands.

Future Outlook

In the following paragraphs we shall see that the pressure-vessel market is to show a steady growth, from 2024 to 2032, and is to rise from $ 50.77 billion to $ 76.30 billion, or at a CAGR of 5.22%. This growth is due to the growing demand for energy, particularly in the petroleum industry, and also to the increasing use of pressure-vessels in various industries, such as chemicals, pharmaceuticals, and food. As industry continues to grow and modernize, the need for efficient and safe pressure-vessels will continue to drive market penetration, and the rate of usage will rise significantly in both emerging economies and mature markets. In addition, technological advancements, such as the development of lightweight materials and improved manufacturing processes, are expected to drive the market further. In particular, the introduction of 3D printing and new welding techniques will not only increase the efficiency and safety of pressure-vessels, but will also reduce their cost and, as a result, increase their availability to a wider range of industries. The market will also benefit from the stricter regulations in place to ensure safety and compliance with the environment. The use of eco-friendly materials and manufacturing processes in the manufacture of pressure-vessels will also be a major trend, and will be in line with the global drive to reduce carbon emissions and increase efficiency.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 45.2 Billion |

| Market Size Value In 2023 | USD 47.9 Billion |

| Growth Rate | 6.0% (2023-2032) |

Pressure Vessel Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.