Market Trends

Key Emerging Trends in the Rheology Modifiers Market

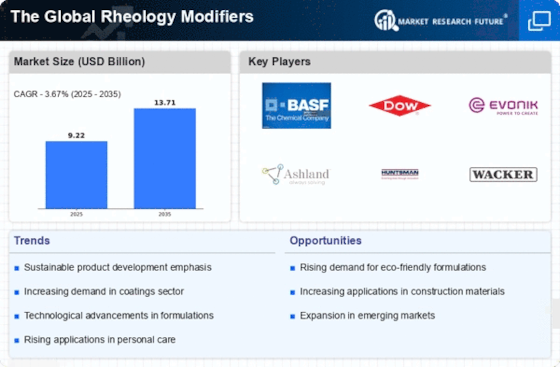

The rheology modifiers market is undergoing significant trends, driven by a combination of technological advancements, diverse applications across industries, and the evolving need for tailored material properties.

Expanding Applications in Paints and Coatings: A prominent trend in the rheology modifiers market is the expanding use in the paints and coatings industry. Rheology modifiers play a crucial role in controlling the viscosity, stability, and application properties of paints and coatings. As the demand for high-performance and visually appealing coatings rises across construction, automotive, and industrial sectors, the use of rheology modifiers continues to grow.

Rising Demand in Personal Care Products: The personal care industry is witnessing a rising demand for rheology modifiers in the formulation of cosmetics, lotions, and creams. These modifiers contribute to the texture, stability, and feel of personal care products, enhancing their overall performance. The trend towards specialty and customized personal care items is driving the adoption of rheology modifiers in this sector.

Focus on Water-Based Formulations: Environmental considerations are influencing a trend towards water-based formulations in various industries. Rheology modifiers are playing a key role in water-based systems, offering stability and viscosity control without the use of volatile solvents. This trend aligns with the industry's efforts to reduce environmental impact and meet regulatory standards for low VOC (volatile organic compound) content.

Advancements in Bio-Based Rheology Modifiers: Ongoing advancements in the development of bio-based rheology modifiers are shaping the market. Manufacturers are exploring sustainable and renewable sources to create bio-based alternatives that meet performance requirements while reducing reliance on fossil fuels. This trend reflects the broader industry movement towards eco-friendly and green formulations.

Increasing Use in Adhesives and Sealants: Rheology modifiers find increasing applications in adhesives and sealants, contributing to improved performance characteristics. In adhesive formulations, rheology modifiers enhance the bond strength, workability, and curing properties. Their role in ensuring proper viscosity and application control is crucial in the adhesives and sealants industry, especially in construction and automotive applications.

Global Supply Chain Dynamics: The rheology modifiers market is influenced by global supply chain dynamics, including the availability of raw materials and trade relationships. Fluctuations in raw material prices and geopolitical factors can impact the overall cost structure of rheology modifiers, influencing market trends and dynamics.

Rise in Demand for Non-Phthalate Modifiers: With increasing regulatory scrutiny on phthalates, there is a rising demand for non-phthalate rheology modifiers. Industries such as plastics, coatings, and adhesives are seeking alternatives that provide effective performance while meeting stringent regulatory standards. The market is responding with the development of non-phthalate options to cater to this demand.

Technological Innovations in Nano-Rheology Modifiers: Technological innovations in nano-rheology modifiers are contributing to the development of high-performance materials. Nano-scale modifiers offer precise control over rheological properties, enabling industries to achieve desired characteristics in their formulations. The application of nano-rheology modifiers is gaining attention in sectors where fine-tuned control is essential.

Customization and Tailored Solutions: Collaboration between rheology modifier manufacturers and end-users for customized solutions is becoming more prevalent. This collaborative approach allows manufacturers to understand specific industry requirements, leading to the development of tailored rheology modifier solutions. Customization contributes to the versatility of rheology modifiers, making them adaptable to unique challenges in various sectors.

Growing Application in the Oil and Gas Industry: The oil and gas industry is recognizing the benefits of rheology modifiers in drilling fluids and cementing applications. Rheology modifiers enhance the viscosity and stability of these fluids, contributing to efficient drilling operations. The demand for rheology modifiers in the oil and gas sector is driven by the need for high-performance solutions in challenging environments.

Focus on Rheology Modifiers for 3D Printing: As 3D printing technology advances, there is a growing focus on rheology modifiers tailored for additive manufacturing processes. These modifiers play a crucial role in controlling the flow and consistency of printing materials, ensuring precise layering and improved print quality. The evolution of rheology modifiers for 3D printing aligns with the broader trends in additive manufacturing.

Leave a Comment