Global Robotics Welding Market Overview:

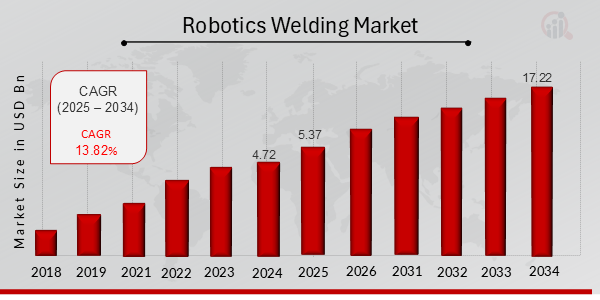

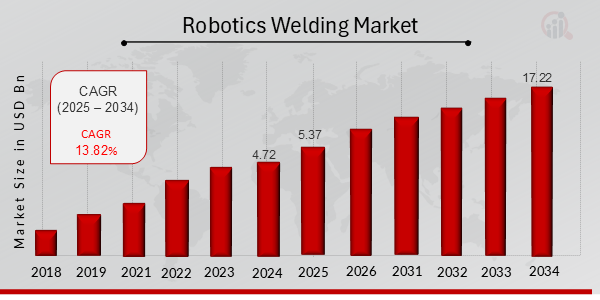

As per MRFR analysis, the Robotics Welding Market Size was estimated at 4.72 (USD Billion) in 2024. The Robotics Welding Market Industry is expected to grow from 5.37 (USD Billion) in 2025 to 17.22 (USD Billion) till 2034, at a CAGR (growth rate) is expected to be around 13.82% during the forecast period (2025 - 2034).

Key Robotics Welding Market Trends Highlighted

The Robotics Welding Market is highly expected to witness growth owing to some prominent reasons. The growth of the robotic welding market is attributed to the growing integration of automation in the manufacturing sectors, especially in the case of robotic welding, which improves quality and efficiency. With the development of technological features such as AI, the welding robots are also equipped with advanced features, increasing their accuracy and versatility. Furthermore, the shift to high-strength, lightweight materials, particularly in the automotive and aerospace industries, provides a platform for robotic welding to be adopted in these industries.

Common market drivers include labor shortages and increased costs of labour as well as the need to boost productivity and efficiency. Also, more complex welding techniques and requirements for high-precision welds are contributing to expansion as well. Additionally, the market growth is further spurred by policies and programs that promote the use of automation and robotics.

The most recent advanced robotics welding market trend is the increasing implementation of collaborative robots that assist human operators in performing tasks accurately and safely. Another development that is gaining popularity is the cloud-based welding management systems that offer weld management in the cloud, enhancing the process with available real-time information. In addition, the use of AR and VR technologies is facilitating the remote monitoring, training, and maintenance of welding robots thereby improving operational efficiency and reducing costs.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Robotics Welding Market Drivers

Rising Demand for Automation in Manufacturing

“A major factor driving growth for the Robotics Welding Market Industry is the increasing need for automation of manufacturing processes. Robotics welding solutions are the ideal of many manufacturers trying to improve the efficiency of their products and to reduce the costs of the labor they have to pay. As such, robotic welding systems are commonly used as well as being faster, more precise and more consistent than traditional ones.

They can also work 24/7, which further boosts their productivity and reduces the productiveness downtime. Robotics welding is usually used in high-volume production lines, specifically in the automotive industry: manufacturers use these technologies to ensure their vehicles are of higher quality and to reduce time and costs spent on vehicle welding. Other industries employing robotics welding include companies working in the fields of aerospace, shipbuilding and construction.”.

Advancements in Robotics Technology

The rapid advancements in robotics technology are another key driver of growth for the Robotics Welding Market Industry. The development of new technologies, such as collaborative robots (cobots), is making robotics welding more accessible and easier to use for manufacturers of all sizes. Cobots are designed to work safely alongside human workers, enabling them to collaborate on complex tasks.

They are also more flexible and adaptable than traditional industrial robots, making them suitable for a wider range of welding applications.Additionally, the development of new welding techniques, such as laser welding and friction stir welding, is expanding the capabilities of robotics welding systems and increasing their adoption in various industries.

Government Initiatives and Support

Apart from industrial applications, government initiatives and support are complementing the market growth, regarding the Robotics Welding Market Industry. Various governments are investing in the research and development of robotics as they acknowledge it to be a lucrative investment that can change the face of manufacturing and other industries. They also offer financial incentives to businesses and tax breaks to those implementing robotics solutions.

For instance, in the U.S., the government has formed RMII and other programs to push robotics in manufacturing. These initiatives are making welding solutions more affordable and accessible and add to the growth of the market.

Robotics Welding Market Segment Insights:

Robotics Welding Market Type Insights

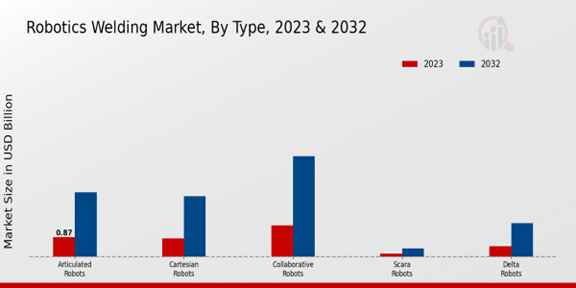

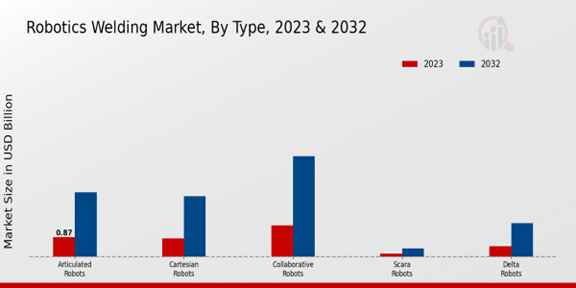

Type segmentation in the Robotics Welding Market means its division into Articulated Robots, Cartesian Robots, Collaborative Robots, SCARA Robots, and Delta Robots. The Articulated Robots has the highest market share in 2023 and will continue to be the leader within the analyzed period. Articulated robots are highly flexible and precise, which is why they can be used for multiple welding purposes, including even complicated and delicate tasks.

The next type that will experience certain growth is Cartesian Robots, as they are considered to be the most cost-effective and easy to use.Due to their qualities, the above type may be used in various conditions, including in high-pressure manufacturing environments requiring high precision and repeatability. Collaborative Robots are also getting more popular as they can perform various tasks without being separated from people with special sensors and other safety technology. At the same time, with humans, the above type uses relatively simple end-effectors, which limit the kinds of welds they can perform.

SCARA robots are among the fastest ones, and they have the smallest warranties due to high precision.The above type may be used for the welding of microchips and other electronic components; delta robots are the fastest and are used in applications requiring complex welding paths. Their simplest use is in the food and beverage industry, where delta robots are used to package and weld food. Finally, the Robotics Welding Market will experience 13.82 percent CAGR growth, reaching an overall valuation of 11.67 billion USD by 2032.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Robotics Welding Market Application Insights

The Robotics Welding Market segmentation by application includes Automotive, Machinery, Electronics, Aerospace, and Medical. The automotive segment accounted for the largest share of the Robotics Welding Market in 2023 and is projected to maintain its dominance over the forecast period.

The growth of the automotive industry, particularly in emerging economies like China and India, is driving the demand for robotics welding in the automotive sector. The machinery segment is also expected to witness significant growth over the forecast period.The increasing demand for automation in various industries, such as metal fabrication and construction, is driving the growth of this segment. The electronics segment is another major application area for robotics welding.

The growing demand for consumer electronics and the increasing adoption of robotics in electronics manufacturing are contributing to the growth of this segment. The aerospace segment is also expected to witness steady growth over the forecast period. The growing demand for lightweight and efficient aircraft is driving the adoption of robotics welding in the aerospace industry.The medical segment is expected to witness moderate growth over the forecast period. The increasing adoption of robotics in medical applications, such as surgical robots and rehabilitation robots, is driving the growth of this segment.

Robotics Welding Market Welding Type Insights

The Robotics Welding Market is segmented based on Welding Type into Arc Welding equipment, Spot Welding, Laser Welding, and MIG Welding. The Arc Welding segment accounted for the largest market share in 2023 and is expected to maintain its dominance throughout the forecast period. The growth of this segment can be attributed to the increasing adoption of arc welding robots in various industries, including automotive, aerospace, and shipbuilding.

The Spot Welding segment is expected to witness significant growth over the forecast period due to its wide application in the automotive industry.Laser Welding is expected to gain traction during the forecast period owing to its high precision and efficiency. MIG Welding is also expected to experience growth due to its versatility and cost-effectiveness. The rising demand for automation in welding processes, coupled with the increasing adoption of robotics in manufacturing industries, is driving the market growth.

Robotics Welding Market Payload Capacity Insights

The payload capacity segment is a crucial aspect of the Robotics Welding Market segmentation. It categorizes welding robots based on the maximum weight they can handle during welding operations. The 'Up to 10 kg' segment caters to lightweight applications such as small-scale manufacturing and electronics assembly. It accounted for a significant market share in 2023 due to its versatility and cost-effectiveness.

The '10-50 kg' segment is suitable for medium-duty welding tasks, including automotive and aerospace components. It is projected to witness steady growth over the forecast period.The '50-200 kg' segment targets heavy-duty industrial applications, such as shipbuilding and construction. It is expected to contribute substantially to the Robotics Welding Market revenue by 2024 and beyond. The 'Over 200 kg' segment addresses highly demanding welding requirements in industries like mining and heavy equipment manufacturing. Its growth potential is attributed to the increasing adoption of automated welding solutions for large-scale projects.

Robotics Welding Market Reach Insights

The Reach segment is a crucial aspect of the Robotics Welding Market, offering insights into the range of applications for robotic welding systems. The market is segmented into four sub-segments based on reach: Up to 1 meter, 1-2 meters, 2-5 meters, and Over 5 meters.

Each sub-segment caters to specific industry needs, such as small-scale welding in close quarters or large-scale welding in open areas. The "Up to 1-meter" sub-segment is projected to hold a significant share of the Robotics Welding Market revenue in 2024, driven by its versatility and suitability for confined spaces.It is commonly used in automotive, electronics, and medical device manufacturing, where precision and flexibility are paramount. The "1-2 meters" sub-segment follows closely, with applications in industries such as construction, shipbuilding, and heavy machinery manufacturing.

The "2-5 meters" sub-segment is expected to witness steady growth, catering to industries such as aerospace, automotive, and shipbuilding, where larger workpieces and complex geometries require extended reach. The "Over 5 meters" sub-segment holds potential for growth in industries such as shipbuilding, offshore construction, and wind turbine manufacturing, where long-reach systems are essential for reaching remote or inaccessible areas.

Overall, the Reach segment in the Robotics Welding Market is poised for growth, driven by increasing automation and technological advancements. The market segmentation provides valuable insights into the diverse applications and industry-specific requirements for robotic welding systems, enabling manufacturers and end-users to make informed decisions.

Robotics Welding Market Regional Insights

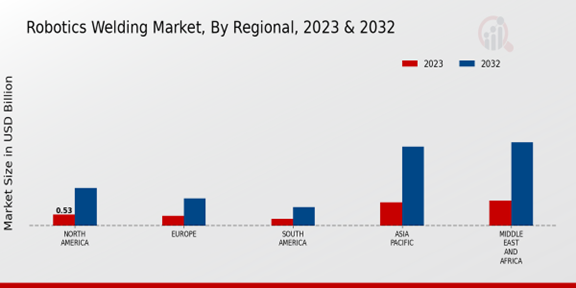

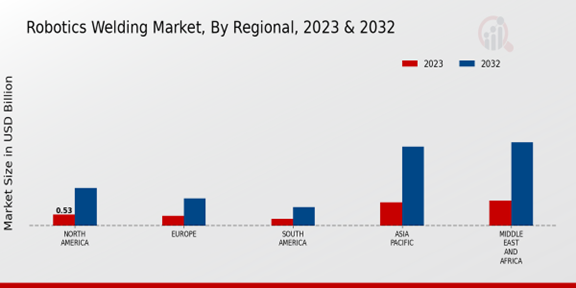

Regionally, North America held the largest market share in 2023, accounting for over 35% of the global revenue. The region's dominance can be attributed to the strong presence of the automotive and manufacturing industries, which are key adopters of robotics welding solutions. Europe held the second-largest market share, followed by APAC.

The APAC region is anticipated to witness the highest growth rate over the forecast period, owing to the increasing adoption of automation in manufacturing industries and the presence of a large automotive sector in countries like China, Japan, and South Korea.South America and MEA are expected to contribute a smaller share to the overall market, but they offer growth opportunities due to the growing investments in infrastructure and industrial development.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Robotics Welding Market Key Players And Competitive Insights:

Major players in the Robotics Welding Market industry are focusing on developing innovative products and expanding their global presence. Leading Robotics Welding Market players are investing heavily in research and development to improve the efficiency and productivity of their robots.

The Robotics Welding Market industry is expected to witness significant growth in the coming years, driven by the increasing adoption of automation in various industries. The competitive landscape of the Robotics Welding Market is characterized by the presence of several key players, including ABB, Yaskawa Electric, FANUC, Kawasaki Heavy Industries, and Nachi-Fujikoshi. These companies are focusing on expanding their product portfolios, increasing their production capacities, and establishing strategic alliances to gain a competitive edge in the market.ABB is a leading player in the Robotics Welding Market industry, with a strong focus on innovation and customer satisfaction. The company offers a wide range of robotic welding solutions, including arc welding robots, spot welding robots, and laser welding robots. ABB robots are known for their high precision, speed, and reliability, making them ideal for a variety of welding applications.

The company has a global presence, with operations in over 50 countries and a strong distribution network that ensures the timely delivery of its products and services. ABB is committed to providing its customers with the best possible solutions and support and is constantly investing in research and development to improve its products and services.Another major player in the Robotics Welding Market is Yaskawa Electric.

The company offers a wide range of industrial robots, including welding robots, painting robots, and assembly robots. Yaskawa Electric robots are known for their high performance, reliability, and ease of use. The company has a global presence, with operations in over 20 countries and a strong distribution network that ensures the timely delivery of its products and services. Yaskawa Electric is committed to providing its customers with the best possible solutions and support and is constantly investing in research and development to improve its products and services.

Key Companies in the Robotics Welding Market Include:

- Fronius International GmbH

- Kawasaki Heavy Industries, Ltd.

- Yaskawa Electric Corporation

- Esab Welding Cutting Products

- Lincoln Electric Holdings, Inc.

Robotics Welding Market Industry Developments

The Robotics Welding Market size was valued at USD 3.64 billion in 2023 and is projected to reach USD 11.67 billion by 2032, exhibiting a CAGR of 13.82% during the forecast period (2025-2034). The market growth is attributed to the increasing adoption of automation in the manufacturing industry, the rising demand for precision welding, and the growing need for improved productivity and efficiency.

The market is also driven by advancements in robotic welding technology, such as the development of collaborative robots and the integration of artificial intelligence (AI) and machine learning (ML) algorithms.Recent news developments in the market include the launch of new robotic welding systems by major players such as ABB, Fanuc, and Yaskawa. These systems offer improved accuracy, speed, and flexibility, making them suitable for a wide range of welding applications. Additionally, the growing adoption of cloud-based robotics platforms is enabling remote monitoring and control of welding robots, enhancing their efficiency and reducing downtime.

Robotics Welding Market Segmentation Insights

Robotics Welding Market Type Outlook

- Articulated Robots

- Cartesian Robots

- Collaborative Robots

- Scara Robots

- Delta Robots

Robotics Welding Market Application Outlook

- Automotive

- Machinery

- Electronics

- Aerospace

- Medical

Robotics Welding Market Welding Type Outlook

- Arc Welding

- Spot Welding

- Laser Welding

- MIG Welding

Robotics Welding Market Payload Capacity Outlook

- Up to 10 kg

- 10-50 kg

- 50-200 kg

- Over 200 kg

Robotics Welding Market Reach Outlook

- Up to 1 meter

- 1-2 meters

- 2-5 meters

- Over 5 meters

Robotics Welding Market Regional Outlook

- North America

- Europe

- South America

- Asia Pacific

- Middle East and Africa

| Report Attribute/Metric |

Details |

|

Market Size 2024

|

4.72 (USD Billion)

|

|

Market Size 2025

|

5.37 (USD Billion)

|

|

Market Size 2034

|

17.22 (USD Billion)

|

|

Compound Annual Growth Rate (CAGR)

|

13.82% (2025 - 2034)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025 - 2034

|

|

Historical Data

|

2019 - 2023

|

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

ABB, HylecAPL, Fronius International GmbH, Stäubli International AG, Kawasaki Heavy Industries, Ltd., Kuka AG, Denso Corporation, Nachi-Fujikoshi Corp., Fanuc Corporation, Yaskawa Electric Corporation, Esab Welding Cutting Products, Kemppi Oy, Lincoln Electric Holdings, Inc., Universal Robots A/S, Panasonic Corporation |

| Segments Covered |

Type, Application, Welding Type, Payload Capacity, Reach, Regional |

| Key Market Opportunities |

Automation of welding processes Increased productivity and efficiency Improved weld quality and accuracy Reduced labor costs and downtime Safety enhancements |

| Key Market Dynamics |

Rising labor costs Increasing demand for automation Technological advancements Growing adoption in the automotive industry Government initiatives supporting automation |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ) :

The Robotics Welding Market is expected to reach a value of 17.22 billion U.S. dollars by 2034, exhibiting a CAGR of 13.82% during the forecast period (2025-2034).

The growth of the robotics welding market is primarily attributed to the increasing adoption of automation in manufacturing industries, rising demand for high-quality and efficient welding processes, and the growing need for improved productivity and cost reduction.

Robotics welding has extensive applications in various industries, including automotive, aerospace, shipbuilding, construction, and general fabrication. It is used in a wide range of welding processes, such as arc welding, spot welding, and laser welding.

North America is anticipated to dominate the Robotics Welding Market throughout the forecast period.

Major players in the Robotics Welding Market include ABB, Yaskawa Electric Corporation, Kawasaki Heavy Industries, Ltd., FANUC Corporation, and OTC Daihen, Inc. These companies offer a wide range of welding robots and systems to meet the diverse needs of various industries.

The robotics welding market faces certain challenges, including the high cost of implementation, the need for skilled labor to operate and maintain the robots, and the potential for job displacement in certain sectors.

The robotics welding market presents significant opportunities for growth due to the increasing adoption of Industry 4.0 technologies, the growing demand for lightweight and durable materials, and the rising focus on sustainability and environmental regulations.

The Robotics Welding Market is projected to grow at a CAGR of 13.82% from 2025 to 2034, driven by the aforementioned factors and the increasing adoption of robotics in manufacturing processes.

Key trends shaping the robotics welding market include the integration of artificial intelligence (AI) and machine learning (ML) technologies, the development of collaborative robots, and the increasing adoption of cloud-based robotics solutions.

The COVID-19 pandemic had a moderate impact on the robotics welding market. While there was a temporary slowdown in demand during the initial stages of the pandemic, the market has since rebounded and is expected to continue its growth trajectory in the coming years.