Growth in Automotive Sector

The Shape Memory Alloy (SMA) Actuators Market is poised for growth, particularly within the automotive sector. The automotive industry is increasingly adopting SMA technology for applications such as active suspension systems, adaptive seating, and engine vibration control systems. The ability of SMAs to provide lightweight and compact solutions aligns with the industry's ongoing efforts to enhance fuel efficiency and reduce emissions. Recent data indicates that the automotive sector accounts for a substantial share of the SMA actuators market, with projections suggesting a steady increase in demand as manufacturers seek innovative ways to improve vehicle performance. As electric and hybrid vehicles gain traction, the integration of SMA actuators is expected to play a crucial role in optimizing various automotive functions, thereby driving market expansion.

Advancements in Medical Devices

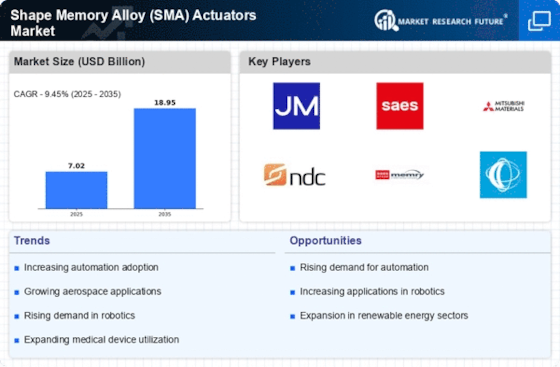

The Shape Memory Alloy (SMA) Actuators Market is experiencing a notable surge in demand due to advancements in medical devices. These actuators are increasingly utilized in minimally invasive surgical tools, prosthetics, and other medical applications. The unique properties of SMAs, such as their ability to return to a predetermined shape upon heating, make them ideal for precise movements in delicate procedures. The market for SMA-based medical devices is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This growth is driven by the increasing need for innovative solutions in healthcare, where precision and reliability are paramount. As the healthcare sector continues to evolve, the integration of SMA actuators into medical devices is likely to enhance patient outcomes and operational efficiency.

Emerging Applications in Aerospace

The Shape Memory Alloy (SMA) Actuators Market is experiencing growth due to emerging applications in the aerospace sector. SMAs are increasingly being utilized in aircraft systems for functions such as wing morphing and control surface actuation. The lightweight nature and high strength-to-weight ratio of SMAs make them particularly attractive for aerospace applications, where weight reduction is critical for fuel efficiency. Recent studies suggest that the aerospace sector is likely to see a compound annual growth rate of approximately 9% for SMA actuators in the next few years. As the industry continues to innovate and seek advanced materials for improved performance, the adoption of SMA technology is expected to play a pivotal role in the development of next-generation aerospace systems.

Increased Focus on Smart Materials

The Shape Memory Alloy (SMA) Actuators Market is benefiting from an increased focus on smart materials across various sectors. As industries seek to incorporate materials that can respond to environmental stimuli, SMAs are emerging as a viable option due to their unique characteristics. The demand for smart materials is projected to grow significantly, with the SMA segment expected to capture a notable share of this market. Industries such as construction, aerospace, and robotics are exploring the potential of SMAs for applications that require adaptive responses to changing conditions. This trend indicates a broader shift towards innovative materials that enhance functionality and efficiency, thereby driving the growth of the SMA actuators market.

Rising Demand in Consumer Electronics

The Shape Memory Alloy (SMA) Actuators Market is witnessing a rising demand in the consumer electronics sector. As manufacturers strive to create more compact and efficient devices, the unique properties of SMAs offer innovative solutions for applications such as camera autofocus mechanisms, mobile phone hinges, and other smart device functionalities. The market for SMA actuators in consumer electronics is projected to grow, with estimates indicating a potential increase of around 8% annually. This growth is fueled by the continuous evolution of technology and consumer preferences for multifunctional and aesthetically pleasing products. The integration of SMA technology allows for enhanced design flexibility and improved performance, making it a preferred choice among electronics manufacturers.