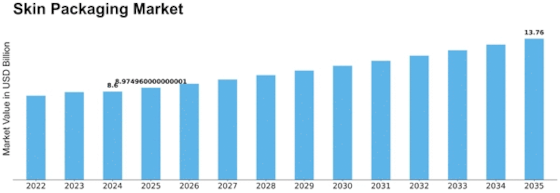

Skin Packaging Size

Skin Packaging Market Growth Projections and Opportunities

The skin packaging market is influenced by various factors that shape its dynamics and determine its performance. Skin packaging is a popular form of packaging used in industries such as food, electronics, and pharmaceuticals to protect products and enhance their visual appeal. One of the primary market factors impacting the global skin packaging market is the increasing demand for packaged food products. As consumer lifestyles become busier and the demand for convenience rises, there is a growing preference for packaged foods that are convenient to store, transport, and consume. Skin packaging offers several advantages for food products, including extended shelf life, tamper resistance, and improved product visibility, driving its adoption in the food industry and contributing to market growth.

The want of reducing the wastage of food and highly nourishing the longevity of the skin products steers up the skin packaging market growth. These packages help in regulating the flavor and maintaining the quality of the skin products by spurring up the shelf life of the food products. Moreover, it has been found that there is a growth in the rising demand for plastic-based packaging that has usurped the market size. It was marked that the demand for plastic packaging has been increased due to accepting plastic-based flexible skin packaging products. It has also been noted that plastic packaging is said to be the best alternative for glass and metal packaging, which is widely used for food covers. This in turn is nurturing the skincare products and is said to be the best solution so offered during the market forecast period. This technique is marked to be the fastest pace concerning industrial units which manufacture products like bearings, bolts, nuts, and many others.

Moreover, technological advancements and innovations significantly influence the global skin packaging market. Manufacturers are constantly innovating to develop skin packaging solutions with improved performance, sustainability, and cost-effectiveness. For example, advancements in packaging materials, such as recyclable plastics and biodegradable films, address growing concerns about environmental sustainability and regulatory requirements. Additionally, innovations in packaging machinery, such as automated skin packaging systems with integrated vacuum sealing and labeling capabilities, improve efficiency and reduce labor costs, driving adoption in industrial applications.

Furthermore, regulatory factors play a crucial role in shaping the global skin packaging market. Regulations and standards related to food safety, hygiene, and labeling drive the adoption of skin packaging solutions that meet regulatory requirements. For example, regulations governing food contact materials, such as the Food Contact Materials Regulation (EC) No 1935/2004 in the European Union, mandate the use of packaging materials that are safe for food contact. Similarly, regulations related to product labeling, such as the Nutrition Labeling and Education Act (NLEA) in the United States, require accurate and informative labeling on packaged food products. Compliance with regulatory requirements is essential for skin packaging manufacturers to access key markets and maintain customer trust.

Market dynamics such as supply chain considerations and technological advancements also impact the global skin packaging market. The skin packaging supply chain involves multiple stages, including the sourcing of raw materials, manufacturing of packaging materials, production of skin packaging systems, and distribution to end-users. Disruptions at any stage of the supply chain, such as raw material shortages, transportation bottlenecks, or regulatory challenges, can affect the availability and pricing of skin packaging. Additionally, advancements in skin packaging technologies, such as modified atmosphere packaging (MAP) and active packaging solutions, improve product freshness and shelf life, driving adoption in the food industry.

Moreover, market factors such as globalization and trade policies influence the global skin packaging market. As skin packaging manufacturers expand their operations to new markets and regions, there is a growing demand for packaging solutions that comply with local regulatory requirements and cultural preferences. Additionally, trade policies, tariffs, and international agreements related to packaging materials and machinery can impact the competitiveness of skin packaging manufacturers in global markets, affecting market dynamics and pricing. Understanding these market factors and adapting manufacturing and distribution strategies accordingly is essential for skin packaging manufacturers to remain competitive in the dynamic and evolving global market.

Leave a Comment