Market Trends

Key Emerging Trends in the Specialty Films Market

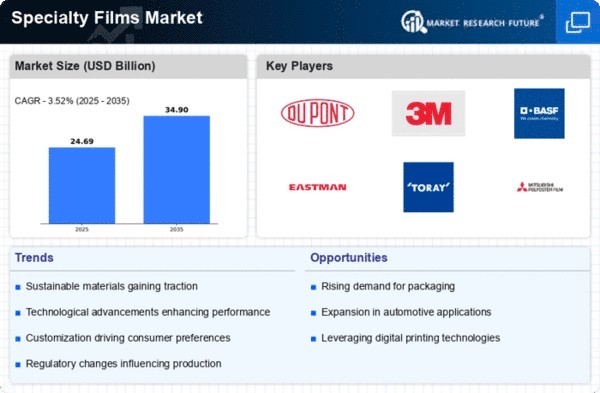

The specialty films market, a critical segment within the broader packaging and industrial materials industry, is currently influenced by several noteworthy trends that define its dynamics. A comprehensive understanding of these market trends is essential for industry stakeholders to make informed decisions, stay competitive, and capitalize on emerging opportunities within this evolving market.

Growing Emphasis on Sustainable Films:

The specialty films market is witnessing a growing emphasis on sustainable films as environmental concerns gain prominence. Manufacturers are investing in the development of biodegradable, compostable, and recyclable specialty films to address consumer and regulatory demands for eco-friendly packaging solutions. Rise of Smart Packaging Solutions:

Smart packaging solutions, incorporating specialty films with functionalities such as barrier properties, antimicrobial coatings, and RFID technology, are gaining traction. The integration of smart features enhances product safety, shelf life, and provides interactive elements for consumers, catering to the demand for innovative packaging solutions. Increasing Demand for Flexible Packaging:

The demand for flexible packaging solutions continues to drive the specialty films market, particularly in the food and beverage industry. Specialty films offer versatility, lightweighting, and extended shelf life, contributing to their adoption in flexible packaging applications. Technological Advancements in Film Coatings:

Technological advancements in film coatings are influencing the specialty films market, enhancing functionalities such as barrier properties, heat resistance, and optical clarity. Nano-coatings, plasma treatments, and other innovations contribute to the development of films with advanced performance characteristics. Rapid Growth in Electronics and Displays:

The electronics and displays sector is emerging as a significant consumer of specialty films, particularly in applications such as touchscreens, flexible displays, and electronic components. Specialty films with optical clarity, conductivity, and protective features cater to the evolving needs of the electronics industry. Focus on High-Performance Barrier Films:

High-performance barrier films are in demand, driven by the need for extended shelf life and protection against external factors such as moisture, oxygen, and UV radiation. Specialty films with enhanced barrier properties find applications in pharmaceuticals, food packaging, and other industries requiring stringent protection for sensitive products. Preference for Bioplastics and Bio-Based Films:

Bioplastics and bio-based films are gaining preference in the specialty films market as alternatives to traditional petroleum-based films. The biodegradability and reduced environmental impact of films derived from renewable resources align with the broader industry push towards sustainability. Expanding Applications in Construction and Automotive:

The specialty films market is expanding its applications beyond packaging, finding use in construction materials, automotive interiors, and architectural films. Films with properties such as UV resistance, durability, and aesthetic appeal contribute to their adoption in non-packaging applications. Customization for Specific End-User Industries:

Customization of specialty films to meet the specific requirements of end-user industries is a prevailing trend. Manufacturers collaborate with customers to develop films tailored for unique applications, addressing challenges in diverse sectors such as healthcare, agriculture, and automotive. Digital Printing on Specialty Films:

Digital printing on specialty films is gaining popularity, allowing for high-quality, customizable graphics and designs on packaging materials. The capability for digital printing enhances the visual appeal of specialty films, particularly in the labels and graphics industry. Globalization and Market Expansion:

The specialty films market is influenced by globalization trends, with manufacturers expanding their market reach to cater to diverse regional demands. International collaborations, strategic alliances, and the global nature of industries such as packaging contribute to the market's geographical distribution. Focus on Antimicrobial Films for Healthcare:

The healthcare industry is driving the demand for specialty films with antimicrobial properties to ensure hygienic and sterile packaging. Antimicrobial films find applications in medical packaging, pharmaceuticals, and healthcare-related products.

Leave a Comment