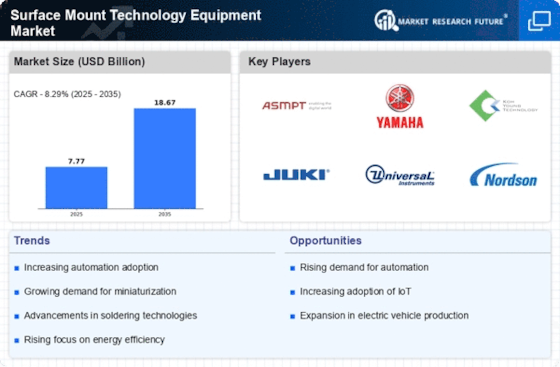

Top Industry Leaders in the Surface Mount Technology Equipment Market

Competitive Landscape of Surface Mount Technology Equipment Market:

The Surface Mount Technology (SMT) equipment market, where tiny robots dance a precise ballet with chips and solder. From smartphones to spaceships, SMT equipment meticulously assembles electronics, wielding miniature soldering irons and laser beams to build the circuitry of our modern world. In this dynamic arena, established giants and nimble innovators clash, all vying for a larger share of the soldering stage. Let's dissect the key strategies and players shaping this captivating scene.

Key Players:

- CyberOptics Corporation

- Keystone Electronics

- Orbotech Ltd.

- Mycronic AB

- Hitachi High-Technologies Corporation

- Nordson Corporation

- Fuji Machine Manufacturing Co. Ltd.

- Assembly Systems

Strategies Adopted by key Players:

- Technological Differentiation: Companies compete fiercely on technological advancements, focusing on factors like increased speed and accuracy of placement machines, improved solderability and reliability, enhanced inspection systems for defect detection, and intelligent software for process optimization. Developing innovative pick-and-place mechanisms, optimizing solder paste formulations, and integrating machine learning algorithms for predictive maintenance are key differentiators.

- Expanding Application Reach: Moving beyond traditional consumer electronics applications to address the needs of diverse sectors like automotive, aerospace, medical devices, and wearable technologies unlocks new market segments and drives wider adoption. Developing specialized SMT equipment for handling delicate components and complex assemblies is crucial.

- Addressing Cost and Efficiency: Making SMT lines more affordable and efficient is vital for widespread adoption. Offering scalable production solutions, reducing equipment downtime, and simplifying maintenance procedures are key strategies.

- Building Partnerships and Collaborations: Fostering partnerships with electronics manufacturers, component suppliers, software developers, and research institutions accelerates innovation, shares expertise, and expands market reach. Collaborating on industry standards, developing reference designs, and promoting the benefits of automation contribute to market growth.

Factors for Market Share Analysis:

- Revenue Generated: This straightforward metric reflects a company's market penetration and financial strength.

- Number of SMT Machines Sold: Understanding the volume of deployed equipment provides insight into customer adoption and market reach.

- Technology Advancements: Assessing a company's investment in R&D, patent portfolio, and cutting-edge SMT technologies helps gauge its future competitive edge.

- Customer Satisfaction: Analyzing user feedback and loyalty metrics reveals how effectively a company caters to customer needs and builds brand reputation.

Latest Company Updates:

September 2023- Panasonic Smart Factory Solutions India (PSFSIN) - a subsidiary company of Panasonic Life Solutions India, a major diversified technology corporation - has unveiled its latest high-tech NPM-G line of surface mount technology (SMT) machines, the NPM-GH and NPM-GP. These new modular mounters and screen-printing machines represent a major advance towards implementing "Autonomous Factory" systems, inaugurating a new phase of precision and efficiency in assembling cutting-edge Printer Circuit Boards (PCB).

September 2023- Hyve Solutions, a wholly owned subsidiary of TD SYNNEX Corporation and a leading provider of large-scale digital infrastructures, has announced the launch of new Surface Mount Technology (SMT) production lines that increase its manufacturing capabilities in the US. This expansion strengthens Hyve's ongoing pledge to provide customers with a Secure Supply Chain through efficiencies and lead time reductions optimized locally. The new SMT lines are outfitted with the most advanced automated technologies and inspection processes, enabling Hyve to manufacture customized, high-quality motherboards in the US while simultaneously decreasing lead times linked to intricate system boards.