- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

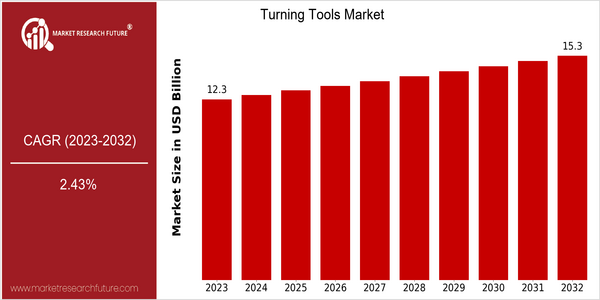

Turning Tools Market Size Snapshot

| Year | Value |

|---|---|

| 2023 | USD 12.33 Billion |

| 2032 | USD 15.3 Billion |

| CAGR (2024-2032) | 2.43 % |

Note – Market size depicts the revenue generated over the financial year

The turning tools market is valued at approximately USD 12.3 billion in 2023 and is expected to reach USD 15.0 billion by 2032, at a CAGR of 2.43% from 2024 to 2032. This steady growth reflects the rising demand for turning tools due to the increasing automation in the manufacturing process and the rising demand for precision components across industries, such as automotive, aerospace, and electronics. As manufacturers are adopting advanced turning tools to improve their production efficiency and reduce production costs, the market for turning tools is expected to expand. Also driving the growth of this market are the technological advancements in tool materials and coatings, which are enhancing tool life and performance. The development of new high-speed steel and carbide tool materials and the integration of smart manufacturing into the manufacturing process are expected to drive the market. The key players in the turning tools market, such as Sandvik Coromant, Kennametal, and Mitsubishi Materials, are undertaking strategic initiatives, such as product launches and collaborations, to strengthen their market positions. They are investing in R&D to develop new turning tools to cater to the changing needs of the industry.

Regional Deep Dive

Turning tools have been in use in the field of agro-manufacturing for a long time, and are now being used in many other branches of industry. The use of these tools is increasing, especially in the United States and Europe. The United States is favored by the development of manufacturing technology and the car industry. Europe is favored by the rigid requirements of quality and the environment. The Asia-Pacific region, which is experiencing rapid industrialization and a growing need for cost-effective manufacturing solutions, is an important part of the world's turning tools industry. The Middle East and Africa (MEA) are growing due to their increasing needs for industrial development, and Latin America is gradually becoming a potential market due to its growing manufacturing base.

North America

- The rise of Industry 4.0 has led to a sharp rise in investment in smart manufacturing. Siemens and GE Digital have specialized in combining the IoT with turning tools to optimize productivity.

- Regulations aiming at the improvement of working conditions and the environment are pushing manufacturers to adopt advanced tools in compliance with these regulations, which are in turn influencing developments in the material and coating of these tools.

- The conversion to electric motors is bringing about a demand for specialized tools, able to handle new materials and designs. Ford and Tesla are investing in advanced machining technology.

Europe

- The European Community's Green Deal has led to the development of the Green Deal in industry, resulting in the manufacture of a green turn-out tool which reduces waste and energy consumption.

- The introduction of ceramic and cermet materials by companies such as Sandvik Coromant, has improved the performance and life of tools used for high-speed machining.

- Competition between the large automobile manufacturers in Germany and France is fostering continuous development and innovation in turning tools.

Asia-Pacific

- The belt and road project is accelerating the development of China's industrial and agricultural machinery, and the demand for the construction and manufacturing industry is also increasing.

- Japan and South Korea are growing rapidly in the field of electronics. The high precision demanded in the manufacture of small parts requires the development of micro-turning tools.

- In India, government initiatives are encouraging the production of lathe tools in India, thus reducing imports and encouraging innovation.

MEA

- The UAE’s Vision 2021 has promoted the development of advanced manufacturing techniques, resulting in an increase in the investment in turning tools.

- Mining in South Africa is a major market for tools which must be hard wearing and can withstand the harsh conditions in the area. The local industry has developed a speciality in the field of such tools.

- The regulations governing the exploitation of the region's resources are gradually being developed, and foreign investment is being encouraged in the development of the industry.

Latin America

- Brazil's manufacturing industry is booming, and with government incentives aimed at modernizing production, there is an increased demand for advanced turing tools.

- The industry of motor cars in Mexico is rapidly developing, attracting foreign capital, and the demand for high-quality tools for the manufacture of these parts is great.

- Local companies have begun to collaborate with foreign companies to improve their technological capabilities in the production of turning tools, thereby strengthening innovation and competitiveness in the region.

Did You Know?

“A turning tool can cut with a precision of 0.0005 mm, and it is therefore essential for high precision applications in the fields of aviation and medicine.” — Machining Technology Journal

Segmental Market Size

The Turning Tools Market is experiencing a steady growth, owing to the increasing demand for precise machining in various industries, such as automobiles, aeronautics and general industry. The need for improved productivity and efficiency in the machining process is driving the demand for turning tools. Also, the increased use of advanced materials that require specialized turning tools is boosting the demand. Also, the growing adoption of automation and Industry 4.0 is increasing the demand for high-performance turning tools that can easily be integrated into smart manufacturing environments.

At present, the use of high-precision turing tools is in its scaled-up phase. The pioneers of innovation and development are Sandvik Coromant and Kennametal. The main application of the turning tool is in CNC machining, where it is essential for the high-precision machining of complex components. The key trends that will accelerate the growth of the market are the promotion of sustainable materials and processes and the technological development of tool coatings and geometries that increase tool life and performance. These trends are influenced by lean production and just-in-time production, which are reshaping the landscape of machining.

Future Outlook

The market for turning tools will show a steady growth from 2023 to 2032, with a market value of $12.3 billion to $15.3 billion, a CAGR of 2.43%. This is mainly due to the rising demand for precision machinery in various industries, such as the automobile, aerospace and machine tools. The turning tools used in the manufacture of these machines are mainly of high quality, which will be in line with the requirements of advanced production methods, and will also be in line with the needs of the industry to reduce production costs and increase productivity. By 2032, it is expected that the proportion of turning tools used in automatic machining will exceed 60%, which will reflect the increasing importance of automation in the manufacturing environment.

The emergence of Industry 4.0, the smart factory and the digitized factory is expected to promote the development of the industry. The development of high-performance tools and coatings will make the tool life longer and the cutting efficiency higher, and will also attract more users. Government policies to improve the manufacturing industry and build a sound foundation for the development of the industry will also provide a good opportunity for the development of the industry. The trend of sustainable development and the concept of green production will also promote the development of the industry, and the tools that are less wasteful and energy-consuming will be more and more popular. The overall trend of the turning tool market is that it will change a lot with the development of science and technology.

Turning Tools Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.