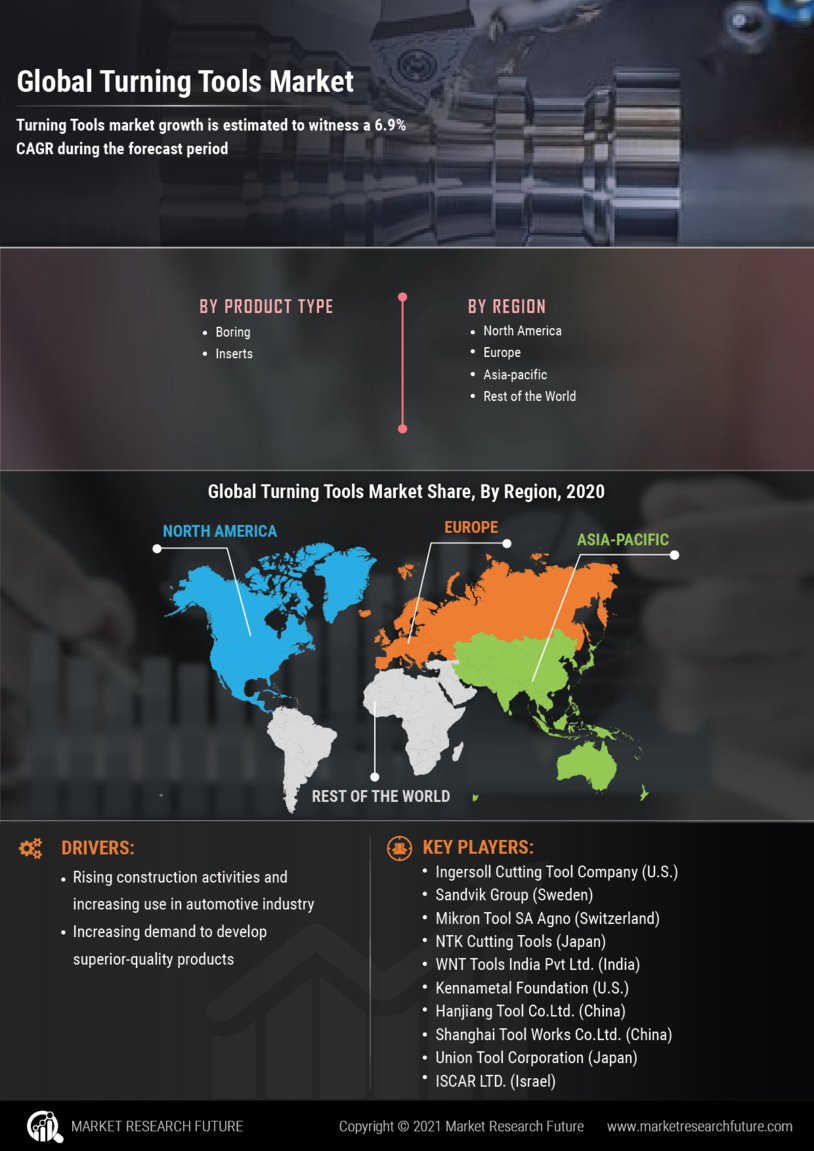

Growth in Automotive Production

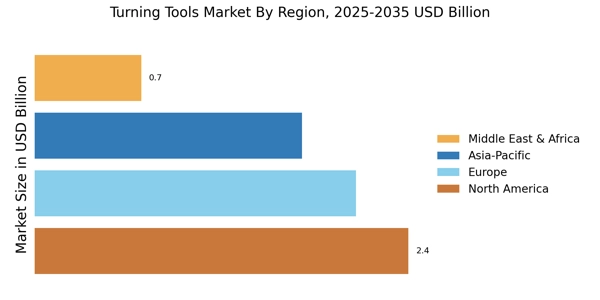

The Turning Tools Market is significantly influenced by the growth in automotive production. With the automotive industry continuously evolving, there is a rising demand for high-quality components that require precision machining. Recent statistics indicate that global automotive production is projected to reach over 100 million units annually by 2026. This surge in production necessitates the use of advanced turning tools capable of producing intricate parts with high accuracy. Furthermore, the shift towards electric vehicles (EVs) is likely to create new opportunities within the Turning Tools Market, as manufacturers adapt their processes to accommodate the unique requirements of EV components. Consequently, the demand for specialized turning tools tailored for the automotive sector is expected to increase, driving market growth.

Increased Focus on Sustainability

The Turning Tools Market is witnessing a growing emphasis on sustainability and environmentally friendly practices. Manufacturers are increasingly adopting sustainable machining processes that minimize waste and reduce energy consumption. This shift is driven by regulatory pressures and consumer demand for greener products. As a result, there is a rising interest in turning tools that are designed for sustainability, such as those made from recyclable materials or those that promote energy-efficient machining. Furthermore, the implementation of sustainable practices in manufacturing is expected to enhance the competitiveness of companies within the Turning Tools Market. By investing in sustainable turning tools, manufacturers can not only comply with regulations but also appeal to environmentally conscious consumers, thereby potentially increasing their market share.

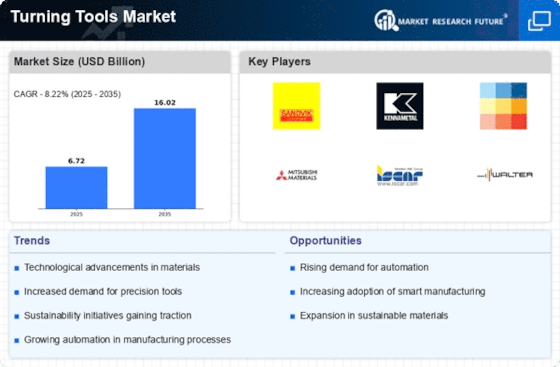

Expansion of the Manufacturing Sector

The Turning Tools Market is poised for growth due to the expansion of the manufacturing sector across various regions. As economies recover and industrial activities ramp up, there is an increasing need for efficient and reliable turning tools. The manufacturing sector, which includes metalworking, machinery, and equipment production, is anticipated to witness a growth rate of around 5% annually. This expansion is likely to create a favorable environment for the Turning Tools Market, as manufacturers invest in upgrading their machinery and tools to enhance productivity. Additionally, the rise of smart manufacturing and Industry 4.0 initiatives is expected to further drive the demand for advanced turning tools that can integrate with automated systems, thereby improving operational efficiency and reducing downtime.

Rising Demand for Precision Engineering

The Turning Tools Market is experiencing a notable increase in demand for precision engineering components. Industries such as aerospace, automotive, and medical devices require high-precision parts, which drives the need for advanced turning tools. According to recent data, the precision engineering sector is projected to grow at a compound annual growth rate of approximately 6% over the next five years. This growth is likely to propel the Turning Tools Market as manufacturers seek tools that can deliver superior accuracy and efficiency. Furthermore, the integration of computer numerical control (CNC) technology in turning processes enhances the capabilities of turning tools, allowing for more complex geometries and tighter tolerances. As a result, the demand for sophisticated turning tools that meet these requirements is expected to rise significantly.

Technological Innovations in Tool Design

The Turning Tools Market is benefiting from ongoing technological innovations in tool design and manufacturing processes. Advancements in materials science, such as the development of high-performance cutting tools made from carbide and ceramic composites, are enhancing the durability and efficiency of turning tools. These innovations allow for longer tool life and improved cutting performance, which are critical factors for manufacturers seeking to optimize their production processes. Additionally, the integration of digital technologies, such as predictive maintenance and real-time monitoring, is transforming how turning tools are utilized in manufacturing environments. As these technologies become more prevalent, the Turning Tools Market is likely to see increased adoption of advanced tools that can provide better performance and reliability.

Leave a Comment