US Dimethylacetamide Market Overview

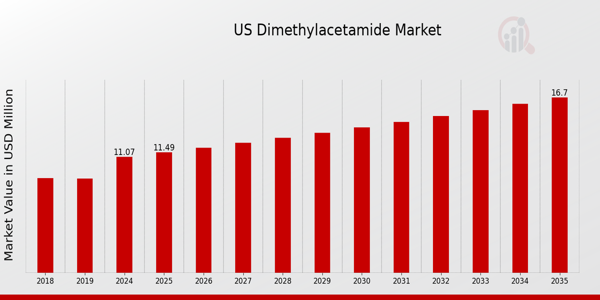

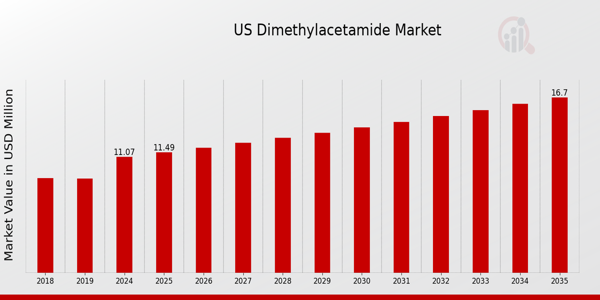

The US Dimethylacetamide Market Size was estimated at 11.02 (USD Million) in 2023. The US Dimethylacetamide Industry is expected to grow from 11.07(USD Million) in 2024 to 16.7 (USD Million) by 2035. The US Dimethylacetamide Market CAGR (growth rate) is expected to be around 3.809% during the forecast period (2025 - 2035).

Key US Dimethylacetamide Market Trends Highlighted

The US Dimethylacetamide market is experiencing notable trends driven by the chemical industry's evolving needs and regulatory shifts. A significant driver for the market is the increasing demand for solvents in the production of pharmaceuticals and agrochemicals, where Dimethylacetamide is often favored for its excellent solvent properties. The push for environmentally friendly and sustainable practices is also influencing the market, as industries seek alternatives with less environmental impact.

Recent trends show that manufacturers are focusing on enhancing the purity and efficiency of Dimethylacetamide, keeping in line with stricter regulatory standards enforced by US agencies.Opportunities in the US market are abundant, particularly as research and development in the pharmaceutical sector accelerates, creating a higher demand for effective solvents like Dimethylacetamide. Furthermore, advancements in manufacturing processes present avenues to capture new markets and improve output efficiency. The rise of specialty chemicals is leading to increased adoption of Dimethylacetamide in high-performance polymers, providing further opportunities to expand its application scope.

Additionally, the trend of vertical integration among chemical manufacturers in the US is allowing for greater control over supply chains and cost structures, enhancing competitive advantage.This consolidation could lead to the development of innovative solutions and varied applications for Dimethylacetamide in end-user industries. Several sectors, especially electronics and automotive, are also starting to utilize Dimethylacetamide more extensively, indicating a diversification of its applications in the US market. Overall, the landscape for the US Dimethylacetamide market is evolving with ample prospects, propelled by shifting demand dynamics and technological advancements.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

US Dimethylacetamide Market Drivers

-

Growing Demand from Pharmaceutical Sector

In the United States, the pharmaceutical sector is witnessing significant growth, acting as a prominent driver for the US Dimethylacetamide Market Industry. According to the American Pharmaceutical Manufacturers Association, the pharmaceutical industry in the US accounted for nearly 12% of the country's GDP in recent years, showcasing a steady upward trend in production and sales.

The increasing complexity of drug formulations and an escalation in Research and Development (R&D) activities have led to a growing demand for solvents like Dimethylacetamide, which are essential for the synthesis of various pharmaceuticals.Notably, major pharmaceutical players such as Pfizer and Merck both acknowledge the necessity of using reliable solvents in their production processes. As a direct consequence, the rising pharmaceutical expenditure and innovation in drug development are likely to drive the growth of the US Dimethylacetamide Market.

Rising Adoption in Agrochemical Applications

The demand for agrochemicals in the United States is growing, further bolstering the US Dimethylacetamide Market Industry. The US Environmental Protection Agency has reported a steady increase in the cultivation of genetically modified organisms, which notably requires effective agrochemical solutions. As a versatile solvent, Dimethylacetamide is essential for the formulation of various pesticides and herbicides. With the increasing focus on sustainable and efficient agricultural practices, major agrochemical companies like Bayer and Dow AgroSciences have adopted Dimethylacetamide in their formulations.This trend highlights the strong link between agrochemical industry innovations and the growth of the Dimethylacetamide market in the US.

Surging Applications in Electronics Manufacturing

Electronics manufacturing is another key sector contributing to the US Dimethylacetamide Market Industry growth. Silicon Valley and other tech hubs in the US continue to expand, leading to increased demand for electronic components and devices. A report from the US Bureau of Economic Analysis highlighted that the electronics manufacturing sector grew by 8% year-on-year, significantly driving the need for effective solvents in the production of semiconductors and electronic components.Companies like Intel and Texas Instruments are major stakeholders in the electronics industry, utilizing Dimethylacetamide in various applications including cleaning and etching processes.

This rise in electronics manufacturing activities is anticipated to propel the demand for Dimethylacetamide in the US.

US Dimethylacetamide Market Segment Insights

Dimethylacetamide Market Application Insights

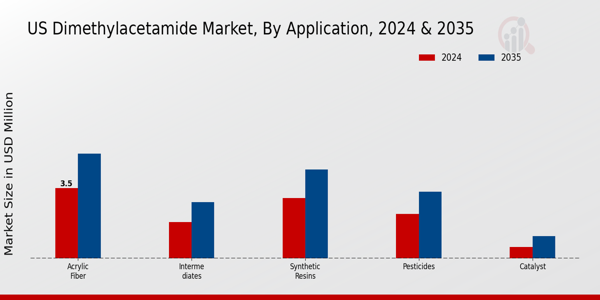

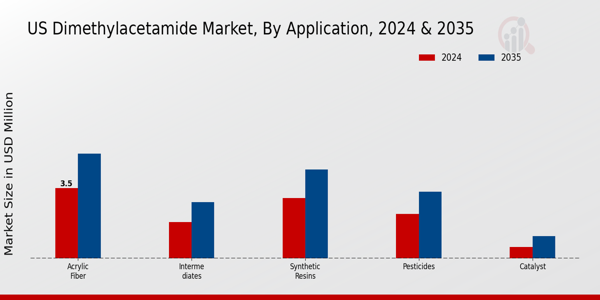

The Application segment of the US Dimethylacetamide Market is diverse and plays a vital role in various industries due to its unique chemical properties. Acrylic fibers, utilized for their desirable characteristics such as strength and resilience, find considerable application in textiles and apparel, thereby contributing significantly to market dynamics. The pesticides domain also demonstrates a strong requirement for Dimethylacetamide, as it acts as a solvent in formulation processes, aiding in the enhancement of pesticide efficacy and stability.

Synthetic resins, primarily used in coatings and adhesives, heavily rely on Dimethylacetamide for effective processing and improved performance, highlighting its importance in the resin manufacturing pipeline. Intermediates represent another crucial application area, as Dimethylacetamide serves as an essential building block in synthesizing various chemical compounds, thus propelling growth in chemical manufacturing sectors. Additionally, the catalyst sector benefits from Dimethylacetamide, where it aids in facilitating chemical reactions and enhancing production efficiency.

The presence of 'others' category points to the versatility of Dimethylacetamide, which extends its utility into multiple applications, such as pharmaceuticals and electronics, where solvents and chemical intermediates are critically needed. Collectively, these applications exhibit a trend towards increasing innovation and sustainability, driven by advancing technology and regulatory standards within the US. As such, the Application segment of the US Dimethylacetamide Market not only showcases robust growth potential but also significant opportunities for continued expansion in the face of evolving market demands and industry practices.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Dimethylacetamide Market End-Use Industry Insights

The US Dimethylacetamide Market, segmented by End-Use Industry, showcases a diverse landscape where various sectors leverage its properties for production processes. The pharmaceutical industry employs Dimethylacetamide for its efficacy as a solvent in drug formulation, contributing significantly to advancements in treatment options and drug development. Meanwhile, the agrochemical sector benefits from its ability to effectively dissolve a range of agricultural chemicals, thereby enhancing pesticide formulations and improving crop yields.

The textile industry relies on Dimethylacetamide as a critical solvent for fibers and dyes, providing enhanced color stability and fabric quality, making it indispensable for high-performance textiles.Similarly, the personal care sector utilizes Dimethylacetamide for its ability to solubilize active ingredients in cosmetics and skincare products, thus facilitating effective product formulation. Other sectors also integrate Dimethylacetamide for various applications, further illustrating its versatile nature. The growth of these industries in the US plays a pivotal role in driving the demand for Dimethylacetamide, contributing to the overall market dynamics and fostering ongoing development in chemical solutions across multiple fields.

With increasing investments in Research and Development across these end-use industries, the US Dimethylacetamide Market is poised for continued significance and expansion.

US Dimethylacetamide Market Key Players and Competitive Insights

The competitive landscape of the US Dimethylacetamide Market is characterized by a dynamic interplay of key players who are actively contributing to the evolution of the industry. As a solvent widely employed in various applications such as pharmaceuticals, agrochemicals, and electronics, dimethylacetamide's utility has garnered attention from multiple stakeholders seeking to enhance their market presence. With growing demand driven by advancements in manufacturing processes and increased production capacities, companies in this sector have been making strategic decisions to capitalize on emerging opportunities while also addressing sustainability concerns.

This has led to innovative product development and enhanced operational efficiencies aimed at fulfilling diverse customer requirements across both established and nascent markets.Vantage Specialty Chemicals has positioned itself as a significant player within the US Dimethylacetamide Market, leveraging its expertise in specialty chemicals to cater to a variety of industries. The company benefits from a robust product portfolio tailored specifically for applications requiring high-performance solvents, which includes dimethylacetamide as a critical component. Vantage Specialty Chemicals focuses on enhancing customer relationships through reliable supply chains and consistent product quality, thereby fostering strong loyalty among its consumer base.

The strategic emphasis on research and development allows the company to continuously improve its offerings, optimizing performance characteristics and environmental compliance, thus reinforcing its position as a trusted supplier in the competitive landscape of dimethylacetamide.Hawkins, Inc. also plays a crucial role in the US Dimethylacetamide Market, providing a range of chemical products that cater to diverse industrial needs. The organization places a strong emphasis on customer service and technical support, ensuring that clients have access to tailored solutions that meet their specific requirements.

Hawkins, Inc.'s key offerings in the domain of dimethylacetamide are complemented by its extensive distribution network, allowing for efficient logistics and prompt delivery across the United States. The company's strengths lie in its commitment to quality and safety, as well as its strategic mergers and acquisitions that bolster its product capabilities and market footprint. These factors collectively position Hawkins, Inc. as a formidable competitor in the US market for dimethylacetamide, enhancing its capacity to respond to emerging trends and customer demands effectively.

Key Companies in the US Dimethylacetamide Market Include

- Vantage Specialty Chemicals

- Zhengzhou YiFeng Chemical

- Shandong Jinling Chemical

US Dimethylacetamide Market Industry Developments

The US Dimethylacetamide Market has been witnessing significant developments recently. In October 2023, Eastman Chemical Company announced a strategic partnership to enhance its production of Dimethylacetamide, aiming to meet the rising demand from the pharmaceutical and chemical sectors. Additionally, in September 2023, Huntsman Corporation reported a significant increase in market share due to heightened demand in agricultural and specialty chemicals, contributing positively to the overall market valuation. Over the last couple of years, companies like BASF and Solvay have also made substantial investments in capacity expansion to cater to the growing needs of end-user industries.

Notably, in March 2022, Vantage Specialty Chemicals completed the acquisition of a smaller competitor, which strengthened its market presence and expanded its product portfolio. The market is projected to experience further growth as major players like Alfa Aesar and Shandong Jinling Chemical continue to innovate and develop sustainable solutions. The ongoing trends reflect an upward trajectory in the US Dimethylacetamide market, driven by increased industrial application and product diversification among key industry players.

US Dimethylacetamide Market Segmentation Insights

Dimethylacetamide Market Application Outlook

Dimethylacetamide Market End-Use Industry Outlook

| Report Attribute/Metric Source: |

Details |

| MARKET SIZE 2018 |

11.02(USD Million) |

| MARKET SIZE 2024 |

11.07(USD Million) |

| MARKET SIZE 2035 |

16.7(USD Million) |

| COMPOUND ANNUAL GROWTH RATE (CAGR) |

3.809% (2025 - 2035) |

| REPORT COVERAGE |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| BASE YEAR |

2024 |

| MARKET FORECAST PERIOD |

2025 - 2035 |

| HISTORICAL DATA |

2019 - 2024 |

| MARKET FORECAST UNITS |

USD Million |

| KEY COMPANIES PROFILED |

Vantage Specialty Chemicals, Hawkins, Inc., BASF, Zhengzhou YiFeng Chemical, Alfa Aesar, Jiangshan Chemical, Zhejiang Jianye Chemical, Solvay, Shandong Jinling Chemical, Nanjing Chemical, Eastman Chemical Company, Merck Group, Taminco, Aceto Corporation, Huntsman Corporation |

| SEGMENTS COVERED |

Application, End-Use Industry |

| KEY MARKET OPPORTUNITIES |

Growing demand in pharmaceutical industry, Expanding applications in agrochemicals, Increased usage in electronics sector, Rising need for solvent-based coatings, Strengthening renewable energy sector initiatives |

| KEY MARKET DYNAMICS |

Increasing demand in industrial applications, Growing use in pharmaceutical manufacturing, Rising adoption in agricultural chemicals, Stringent environmental regulations, Fluctuating raw material prices |

| COUNTRIES COVERED |

US |

Frequently Asked Questions (FAQ):

The US Dimethylacetamide Market is expected to be valued at 11.07 million USD in 2024.

The market is projected to reach a value of 16.7 million USD by 2035.

The expected CAGR for the market from 2025 to 2035 is 3.809%.

The largest application segment is Acrylic Fiber, valued at 3.5 million USD in 2024.

The Pesticides segment is expected to be valued at 3.3 million USD by 2035.

Major players include Vantage Specialty Chemicals, BASF, Solvay, and Eastman Chemical Company among others.

The market value for Synthetic Resins is projected to be 4.4 million USD by 2035.

The Intermediates segment is valued at 1.8 million USD in 2024.

Growth drivers include increasing demand for acrylic fibers and synthetic resins across various industries.

The Catalyst segment is expected to reach a value of 1.1 million USD by 2035.