-

EXECUTIVE SUMMARY

-

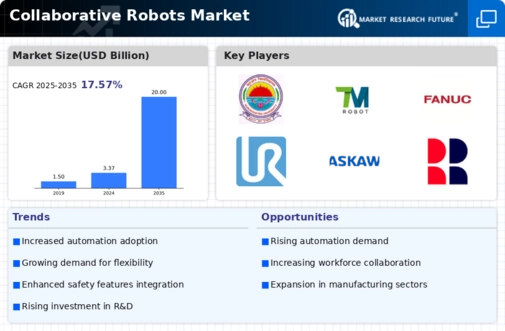

Market Overview

-

Key Findings

-

Market Segmentation

-

Competitive Landscape

-

Challenges and Opportunities

-

Future Outlook

-

\r\n

-

MARKET INTRODUCTION

-

Definition

-

Scope of the study

- Research Objective

- Assumption

- Limitations

-

RESEARCH METHODOLOGY

-

Overview

-

Data Mining

-

Secondary Research

-

Primary Research

- Primary Interviews and Information Gathering Process

- Breakdown of Primary Respondents

-

Forecasting Model

-

Market Size Estimation

- Bottom-Up Approach

- Top-Down Approach

-

Data Triangulation

-

Validation

-

\r\n

-

MARKET DYNAMICS

-

Overview

-

Drivers

-

Restraints

-

Opportunities

-

MARKET FACTOR ANALYSIS

-

Value chain Analysis

-

Porter's Five Forces Analysis

- Bargaining Power of Suppliers

- Bargaining Power of Buyers

- Threat of New Entrants

- Threat of Substitutes

- Intensity of Rivalry

-

COVID-19 Impact Analysis

- Market Impact Analysis

- Regional Impact

- Opportunity and Threat Analysis

-

\r\n

-

COLLABORATIVE ROBOTS MARKET, BY APPLICATION (USD BILLION)

-

Assembly

-

Packaging

-

Palettizing

-

Quality Testing

-

Machine Tending

-

COLLABORATIVE ROBOTS MARKET, BY END USE INDUSTRY (USD BILLION)

-

Automotive

-

Electronics

-

Food and Beverage

-

Pharmaceutical

-

Metal and Machinery

-

COLLABORATIVE ROBOTS MARKET, BY PAYLOAD CAPACITY (USD BILLION)

-

Light Duty

-

Medium Duty

-

Heavy Duty

-

COLLABORATIVE ROBOTS MARKET, BY SALES CHANNEL (USD BILLION)

-

Direct Sales

-

Distributors

-

Online Marketplaces

-

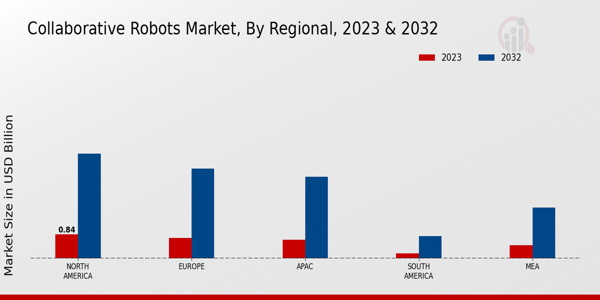

COLLABORATIVE ROBOTS MARKET, BY REGIONAL (USD BILLION)

-

North America

- US

- Canada

-

Europe

- Germany

- UK

- France

- Russia

- Italy

- Spain

- Rest of Europe

-

APAC

- China

- India

- Japan

- South Korea

- Malaysia

- Thailand

- Indonesia

- Rest of APAC

-

South America

- Brazil

- Mexico

- Argentina

- Rest of South America

-

MEA

- GCC Countries

- South Africa

- Rest of MEA

-

\r\n

-

COMPETITIVE LANDSCAPE

-

Overview

-

Competitive Analysis

-

Market share Analysis

-

Major Growth Strategy in the Collaborative Robots Market

-

Competitive Benchmarking

-

Leading Players in Terms of Number of Developments in the Collaborative Robots Market

-

Key developments and growth strategies

- New Product Launch/Service Deployment

- Merger & Acquisitions

- Joint Ventures

-

Major Players Financial Matrix

- Sales and Operating Income

- Major Players R&D Expenditure. 2023

-

COMPANY PROFILES

-

ABB

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

KUKA

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Adept Technology

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Robot System Products

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Nachi Robotic Systems

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Nexa3D

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Auxin Robotics

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Staubli Robotics

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Techman Robot

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

FANUC

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Universal Robots

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Yaskawa Electric

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Rethink Robotics

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Denso Wave

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

Omron

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

APPENDIX

-

References

-

Related Reports

-

LIST OF TABLES

-

\r\n

-

LIST OF ASSUMPTIONS

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

US COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

US COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

US COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

US COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

US COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

CANADA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

CANADA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

CANADA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

CANADA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

CANADA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

GERMANY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

GERMANY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

GERMANY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

GERMANY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

GERMANY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

UK COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

UK COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

UK COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

UK COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

UK COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

FRANCE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

FRANCE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

FRANCE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

FRANCE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

FRANCE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

RUSSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

RUSSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

RUSSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

RUSSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

RUSSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

ITALY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

ITALY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

ITALY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

ITALY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

ITALY COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

SPAIN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

SPAIN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

SPAIN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

SPAIN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

SPAIN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

CHINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

CHINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

CHINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

CHINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

CHINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

INDIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

INDIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

INDIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

INDIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

INDIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

JAPAN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

JAPAN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

JAPAN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

JAPAN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

JAPAN COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

MALAYSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

MALAYSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

MALAYSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

MALAYSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

MALAYSIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

THAILAND COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

THAILAND COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

THAILAND COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

THAILAND COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

THAILAND COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

INDONESIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

INDONESIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

INDONESIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

INDONESIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

INDONESIA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

REST OF APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

REST OF APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

REST OF APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

REST OF APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

REST OF APAC COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

BRAZIL COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

BRAZIL COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

BRAZIL COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

BRAZIL COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

BRAZIL COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

MEXICO COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

MEXICO COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

MEXICO COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

MEXICO COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

MEXICO COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

ARGENTINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

ARGENTINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

ARGENTINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

ARGENTINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

ARGENTINA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

REST OF MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY APPLICATION, 2019-2035 (USD BILLIONS)

-

REST OF MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY END USE INDUSTRY, 2019-2035 (USD BILLIONS)

-

REST OF MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY PAYLOAD CAPACITY, 2019-2035 (USD BILLIONS)

-

REST OF MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY SALES CHANNEL, 2019-2035 (USD BILLIONS)

-

REST OF MEA COLLABORATIVE ROBOTS MARKET SIZE ESTIMATES & FORECAST, BY REGIONAL, 2019-2035 (USD BILLIONS)

-

PRODUCT LAUNCH/PRODUCT DEVELOPMENT/APPROVAL

-

ACQUISITION/PARTNERSHIP

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

\r\n

-

LIST OF FIGURES

-

\r\n

-

MARKET SYNOPSIS

-

NORTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS

-

US COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

US COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

US COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

US COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

US COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

CANADA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

CANADA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

CANADA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

CANADA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

CANADA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS

-

GERMANY COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

GERMANY COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

GERMANY COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

GERMANY COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

GERMANY COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

UK COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

UK COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

UK COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

UK COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

UK COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

FRANCE COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

FRANCE COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

FRANCE COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

FRANCE COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

FRANCE COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

RUSSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

RUSSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

RUSSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

RUSSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

RUSSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

ITALY COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

ITALY COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

ITALY COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

ITALY COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

ITALY COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

SPAIN COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

SPAIN COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

SPAIN COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

SPAIN COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

SPAIN COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

REST OF EUROPE COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

APAC COLLABORATIVE ROBOTS MARKET ANALYSIS

-

CHINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

CHINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

CHINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

CHINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

CHINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

INDIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

INDIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

INDIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

INDIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

INDIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

JAPAN COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

JAPAN COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

JAPAN COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

JAPAN COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

JAPAN COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

SOUTH KOREA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

MALAYSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

MALAYSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

MALAYSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

MALAYSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

MALAYSIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

THAILAND COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

THAILAND COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

THAILAND COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

THAILAND COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

THAILAND COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

INDONESIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

INDONESIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

INDONESIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

INDONESIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

INDONESIA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

REST OF APAC COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

REST OF APAC COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

REST OF APAC COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

REST OF APAC COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

REST OF APAC COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS

-

BRAZIL COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

BRAZIL COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

BRAZIL COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

BRAZIL COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

BRAZIL COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

MEXICO COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

MEXICO COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

MEXICO COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

MEXICO COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

MEXICO COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

ARGENTINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

ARGENTINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

ARGENTINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

ARGENTINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

ARGENTINA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

REST OF SOUTH AMERICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

MEA COLLABORATIVE ROBOTS MARKET ANALYSIS

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

GCC COUNTRIES COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

SOUTH AFRICA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

REST OF MEA COLLABORATIVE ROBOTS MARKET ANALYSIS BY APPLICATION

-

REST OF MEA COLLABORATIVE ROBOTS MARKET ANALYSIS BY END USE INDUSTRY

-

REST OF MEA COLLABORATIVE ROBOTS MARKET ANALYSIS BY PAYLOAD CAPACITY

-

REST OF MEA COLLABORATIVE ROBOTS MARKET ANALYSIS BY SALES CHANNEL

-

REST OF MEA COLLABORATIVE ROBOTS MARKET ANALYSIS BY REGIONAL

-

KEY BUYING CRITERIA OF COLLABORATIVE ROBOTS MARKET

-

RESEARCH PROCESS OF MRFR

-

DRO ANALYSIS OF COLLABORATIVE ROBOTS MARKET

-

DRIVERS IMPACT ANALYSIS: COLLABORATIVE ROBOTS MARKET

-

RESTRAINTS IMPACT ANALYSIS: COLLABORATIVE ROBOTS MARKET

-

SUPPLY / VALUE CHAIN: COLLABORATIVE ROBOTS MARKET

-

COLLABORATIVE ROBOTS MARKET, BY APPLICATION, 2025 (% SHARE)

-

COLLABORATIVE ROBOTS MARKET, BY APPLICATION, 2019 TO 2035 (USD Billions)

-

COLLABORATIVE ROBOTS MARKET, BY END USE INDUSTRY, 2025 (% SHARE)

-

COLLABORATIVE ROBOTS MARKET, BY END USE INDUSTRY, 2019 TO 2035 (USD Billions)

-

COLLABORATIVE ROBOTS MARKET, BY PAYLOAD CAPACITY, 2025 (% SHARE)

-

COLLABORATIVE ROBOTS MARKET, BY PAYLOAD CAPACITY, 2019 TO 2035 (USD Billions)

-

COLLABORATIVE ROBOTS MARKET, BY SALES CHANNEL, 2025 (% SHARE)

-

COLLABORATIVE ROBOTS MARKET, BY SALES CHANNEL, 2019 TO 2035 (USD Billions)

-

COLLABORATIVE ROBOTS MARKET, BY REGIONAL, 2025 (% SHARE)

-

COLLABORATIVE ROBOTS MARKET, BY REGIONAL, 2019 TO 2035 (USD Billions)

-

BENCHMARKING OF MAJOR COMPETITORS

-

\r\n

Leave a Comment