Market Analysis

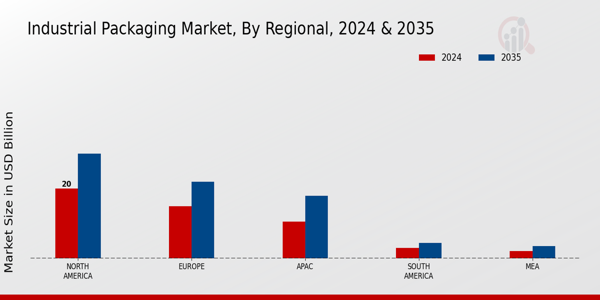

Industrial Packaging Market (Global, 2024)

Introduction

Industrial packaging is a vital part of the supply chain. It is the backbone of safe and efficient transportation of goods in all industries. Industrial packaging has a key role to play in the evolution of the industries. The demand for industrial packaging has increased considerably in the past few years, as a result of the technological developments and changing customer needs. It is a diverse market that covers a wide range of products and materials, including corrugated boxes, pallets, drums, and bulk containers, each designed to meet specific logistics and regulatory requirements. The manufacturers are increasingly adopting eco-friendly materials and methods to reduce the impact on the environment. The growth of e-commerce and globalization has further increased the demand for industrial packaging solutions that are capable of enduring the rigors of modern distribution networks. In this context, it is necessary to analyze the trends, challenges, and opportunities that will shape the future of the industrial packaging market.

PESTLE Analysis

- Political

- In 2024, the industrial packaging market will be affected by the various political factors, including the trade policy and the regulations. The American government has imposed tariffs on imported packaging materials, which has increased the cost of the packaging materials by about 15% for the companies that rely on the import of these materials. The European Union has also imposed stricter regulations on the waste of packaging materials. It is expected that by 2025, more than 70% of the packaging materials used in the European Union will be reusable or recyclabe. The production strategy of the companies in the region will also be affected.

- Economic

- The industrial packaging market in 2024 will be characterized by volatile raw material prices. The price of polyethylene, for example, the most important material for the production of packaging, rose by 10 per cent compared to 2023, due to the disruptions in the supply chain and the growing importance of e-commerce. Moreover, the unemployment rate in industry is expected to remain at around 4.2 per cent, which will lead to a further rise in wages, but also to a reduction in productivity and the effectiveness of operations.

- Social

- Social trends are shaping the industrial packaging market. The public increasingly demands sustainable and eco-friendly packaging solutions. A survey conducted in early 2024 showed that 65% of consumers were willing to pay up to 20% more for products packed in eco-friendly materials. And companies are responding. About 30% of them are planning to replace plastics with biodegradable materials within the next two years.

- Technological

- Industrial packaging is undergoing a change. Technological development, especially automation and smart packaging, is playing an important role. By 2024, it is expected that 40 per cent of the packaging companies will have adopted automation to increase productivity and reduce labor costs by a quarter. In addition, the integration of IoT technology in the packaging industry is growing, and it is expected that 15 per cent of companies will have smart packaging solutions that can provide real-time tracking and inventory management.

- Legal

- The legal aspects influencing the industrial packaging market are those concerning the observance of international standards and regulations. In 2024, the International Organization for Standardization (ISO) revised its ISO 14001 standard for the management of the environment. Now, in addition to the three-year-long reduction of waste by 20 percent, it is required that the company also reduces its own waste by 20 percent. This legal obligation is causing companies to adopt a more sustainable attitude towards their operations and to invest in compliance measures to avoid fines.

- Environmental

- In the industrial packaging market, environment issues are becoming increasingly important, and regulations are being introduced to reduce carbon footprints. In 2024, the world's packaging industry is expected to face a carbon tax of around 50 dollars per ton of carbon dioxide (CO2). This will lead to companies looking for greener alternatives. In addition, circular economy trends will lead to a 25 percent increase in the use of recycled materials in the production of industrial packaging. As companies strive to meet both regulations and customer expectations.

Porter's Five Forces

- Threat of New Entrants

- Industrial packaging has medium-level entry barriers, including capital investment, regulatory compliance and the need for a distribution network. The industry has a high degree of concentration, and the market is dominated by large, established companies with economies of scale and strong brand loyalty. New entrants can find a niche through innovation and technological development, but are unlikely to gain significant market share.

- Bargaining Power of Suppliers

- The bargaining power of the suppliers in the industrial packaging market is relatively low, because there are many suppliers and many sources of raw materials. In addition, most packaging materials such as plastics, metals and paper are a commodity and can be easily replaced. Competition among suppliers makes prices stable and reduces their overall influence on the market.

- Bargaining Power of Buyers

- The buyers in the industrial packaging market are highly influential, especially the large manufacturers who buy in large quantities. Due to the competitive situation, they can negotiate on price and require higher quality or a more specialized product. Moreover, the availability of alternative packaging solutions gives them even more power and makes suppliers compete to offer better conditions and services.

- Threat of Substitutes

- The threat of substitutes in the industrial packaging market is moderate, as alternative packaging solutions, such as biodegradable materials and re-usable containers, are gaining in popularity. However, the particular requirements of industrial packaging, such as ensuring that products are durable and protected during transport, limit the extent to which substitutes can replace traditional packaging materials. Nevertheless, companies must constantly develop new products to remain competitive.

- Competitive Rivalry

- Competition in the industrial packaging market is intense, with many players vying for market share. Competition is based on price, quality, and innovation, and is accompanied by aggressive marketing strategies and frequent product launches. The need for differentiation and the pressure to meet changing customer requirements further intensify competition, making it a dynamic and challenging environment for all.

SWOT Analysis

Strengths

- Robust demand driven by e-commerce and logistics sectors.

- Diverse range of materials and technologies enhancing product offerings.

- Strong focus on sustainability and eco-friendly packaging solutions.

Weaknesses

- High initial investment costs for advanced packaging technologies.

- Dependence on fluctuating raw material prices.

- Limited awareness of innovative packaging solutions among smaller businesses.

Opportunities

- Growing demand for customized packaging solutions.

- Expansion into emerging markets with increasing industrial activities.

- Technological advancements in smart packaging and automation.

Threats

- Intense competition leading to price wars and reduced profit margins.

- Regulatory challenges related to environmental standards.

- Economic downturns affecting industrial production and demand.

Summary

In 2024 the industrial packaging market is characterized by strong demand, a strong focus on sustainability, and significant growth opportunities, especially in bespoke solutions and emerging markets. High costs for investments and regulatory requirements, however, as well as intense competition, may have an adverse effect on profitability. The opportunity lies in exploiting the strengths and reducing the weaknesses to take advantage of the opportunities and minimize the threats.

Leave a Comment