Expansion in Geographical Markets

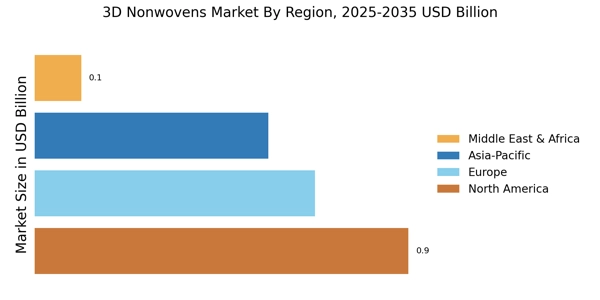

The 3D Nonwovens Market is poised for expansion in various geographical markets, driven by increasing industrialization and urbanization. Emerging economies are witnessing a surge in demand for nonwoven materials across sectors such as construction, automotive, and hygiene products. This trend is likely to be fueled by rising disposable incomes and changing consumer lifestyles, which are creating new opportunities for market players. In 2025, regions with burgeoning manufacturing capabilities are expected to contribute significantly to the growth of the 3D Nonwovens Market. As companies seek to establish a presence in these markets, strategic partnerships and collaborations may become more prevalent, further enhancing market penetration and product availability.

Growth in Healthcare Applications

The 3D Nonwovens Market is witnessing substantial growth in healthcare applications, particularly in the production of medical textiles and personal protective equipment. The unique properties of 3D nonwovens, such as breathability, fluid resistance, and biocompatibility, make them ideal for use in surgical gowns, masks, and wound dressings. As the healthcare sector continues to prioritize patient safety and comfort, the demand for high-quality nonwoven materials is expected to rise. In 2025, the healthcare segment is anticipated to represent a considerable portion of the overall market, reflecting the increasing focus on hygiene and infection control. This growth is further supported by advancements in manufacturing technologies that enhance the performance characteristics of 3D nonwovens, thereby expanding their applicability in medical settings.

Increasing Focus on Sustainability

The 3D Nonwovens Market is increasingly aligning with sustainability initiatives as consumers and manufacturers alike prioritize eco-friendly materials. The shift towards biodegradable and recyclable nonwoven products is becoming more pronounced, driven by regulatory pressures and consumer preferences for sustainable options. In 2025, the market is likely to see a rise in the adoption of bio-based fibers and sustainable production methods, which could significantly alter the supply chain dynamics. This focus on sustainability not only addresses environmental concerns but also opens new avenues for innovation within the 3D Nonwovens Market. Companies that successfully integrate sustainable practices into their operations may gain a competitive edge, appealing to a growing segment of environmentally conscious consumers.

Innovations in Manufacturing Processes

The 3D Nonwovens Market is significantly influenced by innovations in manufacturing processes that enhance the efficiency and quality of nonwoven products. Recent advancements in technologies such as electrospinning and 3D printing are enabling manufacturers to create complex structures with tailored properties. These innovations not only improve production efficiency but also allow for the customization of nonwoven materials to meet specific industry requirements. As a result, the market is likely to see an influx of new products that cater to diverse applications, from filtration to insulation. In 2025, the impact of these technological advancements is expected to be profound, potentially reshaping the competitive landscape of the 3D Nonwovens Market and driving further investment in research and development.

Rising Demand for Lightweight Materials

The 3D Nonwovens Market is experiencing a notable increase in demand for lightweight materials across various sectors. Industries such as automotive and aerospace are increasingly adopting nonwoven materials due to their lightweight properties, which contribute to fuel efficiency and reduced emissions. The lightweight nature of 3D nonwovens allows for innovative designs and applications, enhancing product performance. In 2025, the automotive sector alone is projected to account for a significant share of the 3D Nonwovens Market, driven by the need for materials that meet stringent environmental regulations while maintaining structural integrity. This trend indicates a shift towards more sustainable manufacturing practices, as companies seek to reduce their carbon footprint while improving product functionality.