Cost Efficiency

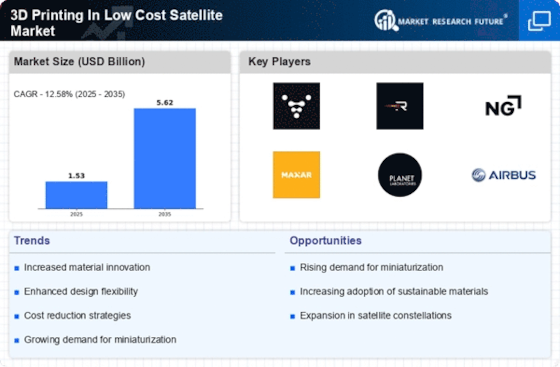

The 3d printing in low cost satellite Market is experiencing a notable shift towards cost efficiency. Traditional satellite manufacturing often incurs high expenses due to complex supply chains and labor-intensive processes. In contrast, 3D printing technology allows for the production of satellite components at a fraction of the cost. Reports indicate that companies utilizing 3D printing can reduce production costs by up to 50%. This cost reduction is particularly appealing for smaller companies and startups, enabling them to enter the market and innovate without the burden of substantial financial investment. As a result, the industry is likely to witness an influx of new players, fostering competition and driving further advancements in satellite technology.

Material Innovation

Material innovation plays a crucial role in the 3D Printing In Low Cost Satellite Market. The development of advanced materials, such as lightweight composites and high-performance polymers, enhances the capabilities of 3D-printed satellite components. These materials not only reduce the overall weight of satellites but also improve their durability and performance in harsh space environments. For instance, the use of carbon fiber reinforced polymers can lead to a weight reduction of up to 30%, which is critical for launch efficiency. As research continues to evolve, the introduction of new materials is expected to expand the range of applications for 3D-printed satellites, thereby attracting more investment and interest in the market.

Increased Accessibility

Increased accessibility is a defining characteristic of the 3D Printing In Low Cost Satellite Market. The democratization of satellite technology is facilitated by 3D printing, which lowers the barriers to entry for new entrants. Smaller companies and research institutions can now design and manufacture satellites without the need for extensive infrastructure or capital investment. This trend is evidenced by the rise of numerous small satellite projects, which have proliferated in recent years. As a result, the industry is likely to see a diversification of satellite missions, ranging from Earth observation to communication, as more entities gain the capability to participate in space exploration.

Customization Capabilities

Customization capabilities are becoming increasingly vital in the 3D Printing In Low Cost Satellite Market. The ability to tailor satellite components to specific mission requirements is a significant advantage of 3D printing technology. Unlike traditional manufacturing, which often relies on standardized parts, 3D printing allows for the creation of bespoke designs that can optimize performance for particular applications. This flexibility is particularly beneficial for niche markets, where unique specifications are essential. As the demand for specialized satellite solutions grows, the customization potential offered by 3D printing is expected to drive further innovation and investment in the industry.

Shortened Development Cycles

The 3D Printing In Low Cost Satellite Market benefits from significantly shortened development cycles. Traditional satellite manufacturing processes can take years, often delaying the deployment of critical technologies. However, 3D printing enables rapid prototyping and iterative design, allowing engineers to quickly test and refine their concepts. This agility is particularly advantageous in a fast-paced technological landscape where timely deployment can provide a competitive edge. Companies have reported reductions in development time by as much as 70%, which not only accelerates time-to-market but also enhances the ability to respond to emerging needs and opportunities in satellite applications.