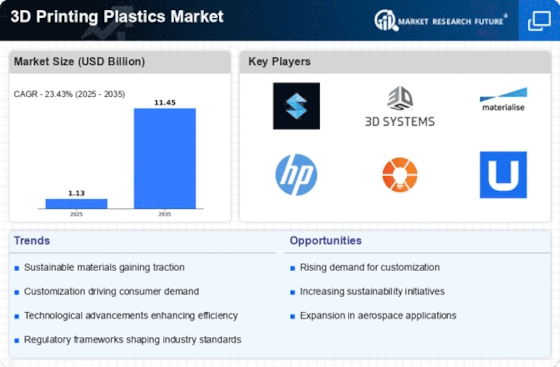

Top Industry Leaders in the 3D Printing Plastics Market

The 3D printing plastics market, fueled by innovation and limitless possibilities, is projected to reach intricate prototypes to revolutionary products, this market shapes the future layer by layer. But beneath the surface lies a fiercely competitive landscape, where established giants and nimble innovators vie for market share.

Strategies Sculpting the Marketplace:

-

Material Masters: Industry titans like BASF, Dow Chemical, DuPont, and DSM leverage their extensive R&D capabilities to develop new, high-performance filaments and resins tailored to specific applications. Their strategies focus on expanding portfolios, strategic acquisitions, and partnerships with leading 3D printer manufacturers. -

Regional Champions: Regional players like Sinopec in China and Mitsubishi Chemical in Japan hold strong positions in their respective markets. They compete on price, cater to regional preferences, and build strong local distribution networks. -

Niche Specialists: Emerging players like Proto Labs and Desktop Metal carve niches with specialty filaments like conductive, biocompatible, or high-temperature resistant materials. They capitalize on unique capabilities and cater to specific customer segments, often at premium prices.

Factors Dictating Market Share:

-

Material Diversity and Performance: Offering a diverse range of filaments and resins with various properties like strength, flexibility, temperature resistance, and biocompatibility attracts a wider customer base and increases market share. Continuous innovation is crucial for staying ahead of the curve. -

Printing Technology Compatibility: Ensuring compatibility with different 3D printing technologies like FDM, SLA, and SLS broadens market reach and caters to diverse customer needs. -

Sustainability and Environmental Impact: Developing recycled, bio-based, or biodegradable filaments addresses environmental concerns and attracts customers seeking green solutions. -

Cost-Effectiveness and Efficiency: Optimizing production processes and offering cost-competitive materials is essential for gaining market share, particularly in price-sensitive segments. -

Technical Support and Customer Service: Providing excellent technical support and building strong customer relationships fosters trust and repeat business, leading to market share consolidation.

Key Players:

- 3D Systems Corporation (US),

- Royal DSM N.V. (Netherlands),

- General Electric (US),

- Stratasys Ltd. (US),

- Hoganas AB (Sweden),

- Materialise NV (Belgium),

- The ExOne Company (US),

- Arkema SA (France),

- Evonik Industries AG (Germany)

Recent Developments:

-

September 2023: Sinopec launches a new online platform for 3D printing materials, offering custom filament designs and on-demand production services. -

October 2023: Proto Labs introduces a revolutionary biocompatible resin for 3D printing medical implants, paving the way for personalized healthcare solutions. -

November 2023: DSM and Mitsubishi Chemical announce a joint venture to develop and market high-performance filaments for 3D printing in extreme environments. -

December 2023: A group of researchers at MIT unveils a 3D printing technique that combines multiple materials within a single filament, enabling printing of objects with complex properties.