Rising Demand for Lightweight Materials

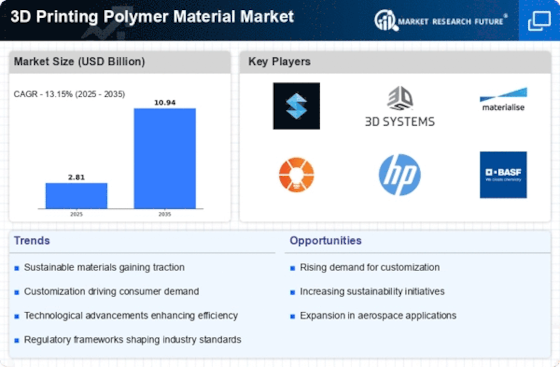

The increasing demand for lightweight materials across various industries is a notable driver for the 3D Printing Polymer Material Market. Industries such as aerospace and automotive are actively seeking materials that reduce weight while maintaining structural integrity. This trend is particularly evident in the aerospace sector, where reducing weight can lead to significant fuel savings and improved efficiency. According to recent data, the use of polymer materials in 3D printing has been projected to grow at a compound annual growth rate of approximately 25% over the next five years. This growth is largely attributed to the need for lightweight components that can be produced quickly and cost-effectively, thereby enhancing the overall performance of end products.

Advancements in 3D Printing Technologies

Technological advancements in 3D printing processes are significantly influencing the 3D Printing Polymer Material Market. Innovations such as improved printing speeds, enhanced resolution, and the development of new polymer materials are expanding the capabilities of 3D printing. For instance, the introduction of multi-material printing techniques allows for the creation of complex geometries and functional parts that were previously unattainable. Market data indicates that the adoption of advanced 3D printing technologies is expected to increase by over 30% in the coming years, driven by the need for rapid prototyping and production in various sectors, including healthcare and consumer goods. These advancements not only improve the efficiency of production but also broaden the application scope of polymer materials in 3D printing.

Customization and Personalization Trends

The trend towards customization and personalization is a significant driver for the 3D Printing Polymer Material Market. Consumers increasingly seek products that reflect their individual preferences and needs, prompting manufacturers to adopt 3D printing technologies. This method allows for the rapid production of tailored products, from consumer goods to industrial components. Market data suggests that the demand for customized 3D printed items is expected to grow by over 25% in the next few years, as businesses recognize the competitive advantage of offering personalized solutions. This trend is particularly evident in sectors such as fashion, where unique designs can be created on-demand, reducing waste and inventory costs. As the market evolves, the ability to provide customized polymer materials will likely become a key differentiator for companies in the 3D printing landscape.

Sustainability and Eco-Friendly Practices

Sustainability initiatives are becoming increasingly important in the 3D Printing Polymer Material Market. As industries strive to reduce their environmental footprint, the demand for eco-friendly materials is on the rise. Biodegradable polymers and recycled materials are gaining traction as viable options for 3D printing applications. Market analysis indicates that the segment of sustainable polymer materials is projected to grow by approximately 15% over the next few years, driven by consumer preferences for environmentally responsible products. Companies are investing in research and development to create sustainable alternatives that do not compromise on performance. This shift towards sustainability not only aligns with global environmental goals but also presents new opportunities for innovation within the 3D printing sector.

Growing Adoption in Healthcare Applications

The healthcare sector's growing adoption of 3D printing technologies is a crucial driver for the 3D Printing Polymer Material Market. The ability to create customized implants, prosthetics, and surgical tools tailored to individual patient needs is revolutionizing medical practices. Recent studies suggest that the use of 3D printed polymer materials in healthcare is expected to grow at a rate of 20% annually, as hospitals and clinics increasingly recognize the benefits of personalized medicine. This trend is further supported by regulatory approvals for 3D printed medical devices, which enhance the credibility and acceptance of these technologies in clinical settings. As healthcare providers seek innovative solutions to improve patient outcomes, the demand for specialized polymer materials in 3D printing is likely to rise.