Market Trends

Key Emerging Trends in the Acrylic Based Elastomers Market

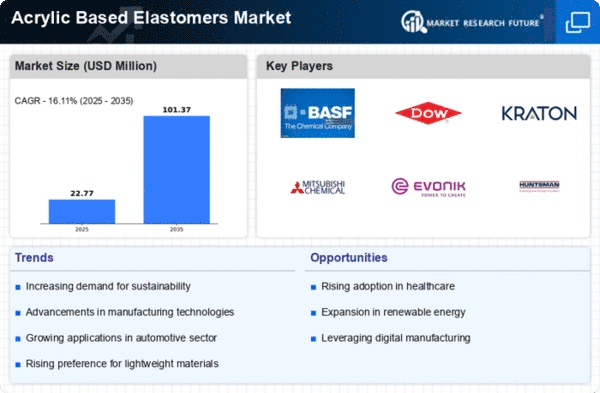

As expected in polymer and elastomer industries’ nature changeability, acrylic-based elastomer industry is presently undergoing remarkable transformations. The versatility and long life of this material has caused dramatic demand shifts of it across many industrial sectors. One major trend in automotive sector is increased use of acrylic made elastomers. These elastomers are ideal for weather stripping, gaskets and seals used in vehicles due to their exceptional resistance to heat, ozone and chemicals. This improves their durability as well as performance. This development goes along with an industrial-wide push towards new materials that would improve fuel economy, limit pollution levels resulting from automobiles, make them safer.

Besides that, there is a significant increase in demand for acrylic-made elastomers from building & infrastructure industries too. Joint sealants; expansion joints; weatherproofing compounds all utilize these types of materials. Acrylic-made elastomers have excellent bonding capability for building up water proofing against wear & tear because they last longer than ‘normal’ ones. The increased need for high performing elastomers in construction related applications comes with worldwide growth of construction industry.

Strict regulations also enforce long-term suitability and low environmental impact on acrylic-based elastomers, including those derived from acrylic. These formulations must meet emission regulations, volatile organic compound (VOC) requirements, as well as general environmental safety compliance. It shows that businesses want to reduce their ecological footprints and improve air quality towards a sustainable environment by adhering to stringent regulations.

Moreover, many parts of the world have seen growths in demand while emerging economies have played a significant role in this trend. For instance, acrylic-based synthetic rubbers are highly demanded as a result of rapid industrialization and urbanization that is taking place around the regions such as Asia-Pacific. These applications encompass automotive industry, construction and general industrial uses. Manufacturers can exploit increasing demands within various sectors by entering these markets within this region’s sub-regions.

Leave a Comment