Rising Environmental Concerns

The Global Acrylic Styrene-Acrylonitrile Resin Market Industry is also shaped by rising environmental concerns, prompting manufacturers to seek sustainable alternatives. Acrylic Styrene-Acrylonitrile resin offers recyclability and lower environmental impact compared to traditional materials, aligning with global sustainability goals. As industries increasingly prioritize eco-friendly practices, the demand for such resins is likely to grow. This shift not only supports environmental initiatives but also enhances the market's appeal to consumers who are becoming more environmentally conscious. The focus on sustainability may drive innovations in resin formulations, further expanding the market's potential.

Expansion in Consumer Electronics

The Global Acrylic Styrene-Acrylonitrile Resin Market Industry is significantly influenced by the expansion of the consumer electronics sector. With the rise of smart devices and home appliances, there is an increasing demand for materials that offer durability and design flexibility. Acrylic Styrene-Acrylonitrile resin is utilized in the production of casings, screens, and various electronic components due to its superior clarity and impact resistance. This trend suggests a promising outlook for the market, as the consumer electronics industry is expected to continue its growth, potentially contributing to the market's valuation of 2500 USD Million by 2035.

Growing Demand in Automotive Sector

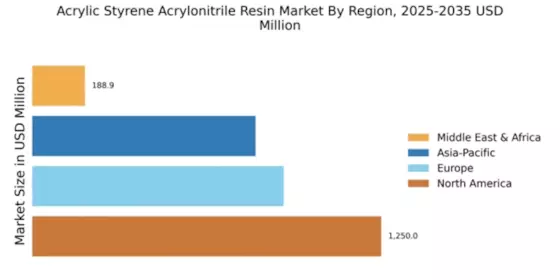

The Global Acrylic Styrene-Acrylonitrile Resin Market Industry is experiencing a notable surge in demand from the automotive sector. This growth is primarily driven by the increasing need for lightweight materials that enhance fuel efficiency and reduce emissions. Acrylic Styrene-Acrylonitrile resin is favored for its excellent mechanical properties and aesthetic appeal, making it suitable for various automotive applications, including interior and exterior components. As the automotive industry continues to evolve, the market is projected to reach approximately 1250 USD Million by 2024, indicating a robust growth trajectory that aligns with the industry's shift towards sustainable practices.

Technological Advancements in Production

The Global Acrylic Styrene-Acrylonitrile Resin Market Industry benefits from ongoing technological advancements in production processes. Innovations in polymerization techniques and material formulations are enhancing the efficiency and quality of resin production. These advancements enable manufacturers to produce resins with improved properties, such as enhanced thermal stability and chemical resistance, which are crucial for various applications. As production methods become more sophisticated, the market is likely to see increased competitiveness and product differentiation. This evolution in technology may lead to a broader range of applications, thereby expanding the market's reach across different industries.

Increasing Adoption in Construction Applications

The Global Acrylic Styrene-Acrylonitrile Resin Market Industry is witnessing increased adoption in construction applications, driven by the need for high-performance materials in building projects. This resin is valued for its weather resistance, durability, and aesthetic qualities, making it suitable for various construction elements such as windows, doors, and roofing materials. As urbanization accelerates globally, the demand for innovative construction solutions is likely to rise, further propelling the market. The anticipated compound annual growth rate of 6.5% from 2025 to 2035 indicates a strong potential for growth in this sector, reflecting the ongoing transformation in construction methodologies.