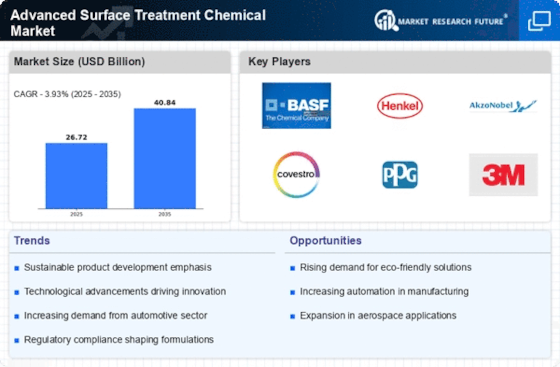

Growth in Aerospace Applications

The aerospace industry is increasingly utilizing advanced surface treatment chemicals to enhance the performance and safety of aircraft components. With the rising focus on fuel efficiency and weight reduction, the Advanced Surface Treatment Chemical Market is poised for growth as manufacturers seek to apply specialized coatings that improve aerodynamic properties and reduce drag. In recent years, the market has seen a shift towards environmentally friendly treatment options, aligning with global sustainability goals. The aerospace segment is expected to contribute significantly to the overall market growth, as advancements in surface treatment technologies continue to evolve, offering new solutions for complex aerospace applications.

Expansion of Electronics Industry

The electronics industry is a key driver of the Advanced Surface Treatment Chemical Market, as the demand for high-performance electronic devices continues to rise. Surface treatment chemicals are essential for enhancing the conductivity, durability, and aesthetic appeal of electronic components. As the market for consumer electronics expands, manufacturers are increasingly investing in advanced surface treatments to ensure product reliability and longevity. In 2025, the electronics segment is anticipated to witness substantial growth, reflecting the ongoing trend towards miniaturization and increased functionality in electronic devices. This growth is likely to further stimulate the Advanced Surface Treatment Chemical Market, as companies seek innovative solutions to meet evolving consumer demands.

Rising Demand from Automotive Sector

The automotive sector is experiencing a notable increase in demand for advanced surface treatment chemicals, driven by the need for enhanced durability and corrosion resistance in vehicles. As manufacturers strive to meet stringent regulatory standards and consumer expectations for quality, the Advanced Surface Treatment Chemical Market is witnessing a surge in the adoption of innovative coatings and treatments. In 2025, the automotive segment is projected to account for a significant share of the market, reflecting a shift towards more sustainable and efficient production processes. This trend is likely to propel the growth of the Advanced Surface Treatment Chemical Market, as companies invest in advanced technologies to improve surface performance and longevity.

Increased Focus on Environmental Regulations

The implementation of stringent environmental regulations is driving the Advanced Surface Treatment Chemical Market towards more sustainable practices. Companies are increasingly required to adopt eco-friendly surface treatment solutions that minimize environmental impact while maintaining performance standards. This shift is prompting manufacturers to invest in research and development of advanced surface treatment chemicals that comply with regulatory requirements. As a result, the market is likely to see a rise in the adoption of water-based and low-VOC formulations, which are becoming more prevalent in various industries. This trend not only supports compliance with regulations but also enhances the overall sustainability profile of the Advanced Surface Treatment Chemical Market.

Technological Innovations in Surface Treatments

Technological advancements are playing a crucial role in shaping the Advanced Surface Treatment Chemical Market. Innovations in nanotechnology, smart coatings, and surface modification techniques are enabling the development of more effective and versatile treatment solutions. These advancements are likely to enhance the performance characteristics of surface treatments, such as improved adhesion, resistance to wear, and self-cleaning properties. As industries seek to leverage these technologies for competitive advantage, the market is expected to experience significant growth. The integration of advanced technologies into surface treatment processes is anticipated to drive the evolution of the Advanced Surface Treatment Chemical Market, fostering new applications and expanding market opportunities.