Aerospace Plastics Size

Aerospace Plastics Market Growth Projections and Opportunities

The Aerospace Plastics Market is influenced by a variety of factors that collectively shape its trends and growth dynamics. One primary driver is the increasing demand for lightweight materials in the aerospace industry to improve fuel efficiency and reduce overall aircraft weight. Aerospace plastics, known for their high strength-to-weight ratio and resistance to harsh environmental conditions, find extensive applications in aircraft interiors, exteriors, and structural components. As the aerospace sector continuously seeks innovative materials to enhance performance and fuel efficiency, the demand for aerospace plastics continues to grow.

Global economic conditions play a pivotal role in the Aerospace Plastics Market. Economic growth and industrialization contribute to increased air travel, driving the demand for new aircraft and retrofitting existing fleets with lightweight materials. Developing economies, experiencing a rise in air travel demand, particularly contribute to the market's growth as they invest in expanding their commercial and military aviation capabilities.

Technological advancements in plastics manufacturing processes impact the market dynamics. Ongoing research and development efforts lead to innovations in aerospace plastics, including advanced composites and thermoplastics. These materials offer superior performance characteristics, such as increased durability, fire resistance, and the ability to withstand extreme temperatures. Companies investing in these technological advancements gain a competitive edge by offering aerospace plastics that meet the stringent requirements of the aerospace industry.

Stringent environmental regulations and a focus on sustainability play a significant role in the Aerospace Plastics Market. As the aviation industry strives to reduce its environmental impact, the adoption of lightweight materials, including aerospace plastics, becomes crucial. These materials contribute to fuel efficiency, lower emissions, and improved overall aircraft performance. Companies aligning their product offerings with sustainability goals are likely to gain favor in the market.

Geopolitical factors and trade dynamics also impact the Aerospace Plastics Market. Fluctuations in trade relations, changes in tariffs, and geopolitical tensions can influence the supply chain and pricing of aerospace plastics. Companies in the market need to stay informed about global trade developments and adjust their strategies to navigate potential risks and capitalize on emerging opportunities in the global market.

Moreover, the commercial aviation sector significantly contributes to the demand for aerospace plastics. As airlines seek ways to enhance fuel efficiency and reduce operating costs, the adoption of lightweight materials becomes a strategic imperative. Aerospace plastics, being integral to achieving weight reduction targets, find extensive use in the production of aircraft interiors, seating, and structural components.

The defense and military aviation sector is another key driver of the Aerospace Plastics Market. Military aircraft require materials that offer high strength, durability, and resistance to extreme conditions. Aerospace plastics play a crucial role in meeting these requirements, contributing to the development of advanced military aircraft with enhanced performance capabilities.

Raw material prices, particularly those of specialty polymers and composites used in aerospace plastics, play a role in shaping the Aerospace Plastics Market. Fluctuations in the costs of these raw materials impact the production costs and pricing of aerospace plastics. Companies in the market must implement effective supply chain strategies and cost management practices to navigate these raw material price dynamics.

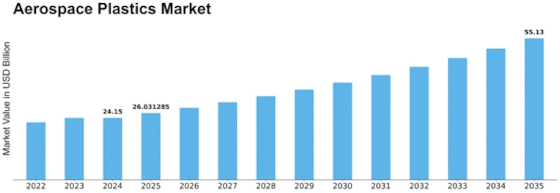

Aerospace Plastics Market Size was valued at USD 19.28 billion in 2022. The Aerospace Plastics industry is projected to grow from USD 20.84 Billion in 2023 to USD 37.98 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 7.79% during the forecast period (2023 - 2030).

Leave a Comment