Research Methodology on Super Engineering Plastics Market

1. Introduction

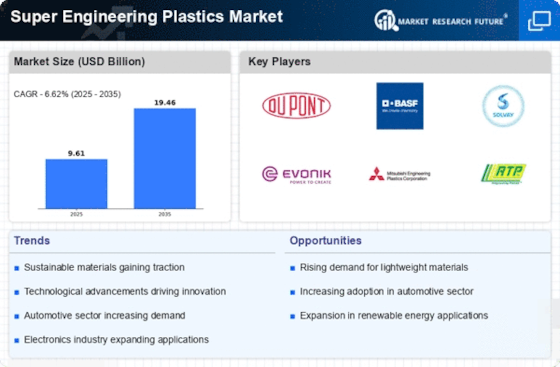

This research study aims to analyze the Super Engineering Plastics Market by examining the various trends, key drivers, opportunities, challenges and key players in the market. The size of the market will also be determined and the potential growth rates over the forecast period analyzed. To achieve this, an extensive research methodology involving both primary and secondary research sources to always ensure accurate and reliable data is applied.

2. Objectives

This research study aims to analyze the Super Engineering Plastics Market with respect to the following objectives:

• To identify the key drivers, opportunities, and challenges in the Super Engineering Plastics Market.

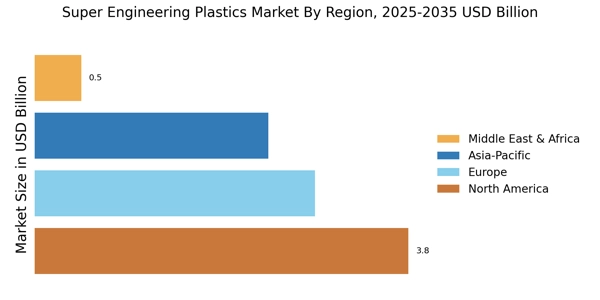

• To analyze the size of the Super Engineering Plastics Market and determine its potential growth over the forecast period 2023 to 2030.

• To identify and profile the key players in the Super Engineering Plastics Market.

3. Research Design

This research study adopts a descriptive approach in order to analyze the Super Engineering Plastics Market in a detailed and comprehensive manner. The research design is mainly explorative in nature as it aims to provide a holistic view of the market including its key drivers, challenges and opportunities as well as the potential growth opportunities.

4. Research Methodology

A five-step procedure is adopted by this research study to carry out the entire market research. This includes the following steps:

• Step One: Identification of Sources of Information

This step involves the primary sources of information that will be used to carry out this research study. It includes secondary sources such as company reports, press releases, industry databases, white papers, government sources, industry associations, journals and magazines and primary sources such as face-to-face interviews, online surveys and Telephonic interviews.

• Step Two: Determination of Research Objectives

In this step, the research objectives are determined which include analyzing the Super Engineering Plastics Market concerning the drivers, opportunities, challenges and potential growth opportunities.

• Step Three: Collection of Data

In this step, the data is collected from secondary sources such as company reports, press releases, industry databases, white papers, government sources, industry associations, journals and magazines and from primary sources such as face-to-face interviews, online surveys and telephonic interviews.

• Step Four: Analysis and Interpretation of Data

The data collected from the secondary and primary sources is then analyzed and interpreted in order to gain meaningful insights into the Super Engineering Plastics Market. This is done using bottom-up and top-down approaches.

• Step Five: Preparation of the Report

The report is then prepared based on the analysis and interpretation of the data, highlighting the key insights, trends and opportunities in the Super Engineering Plastics Market.

5. Research Approach

The research approach adopted for this market research is both qualitative and quantitative in nature. The primary sources of data used in the research are opinion leaders, key industry participants, industry associations, journals and magazines, and industry databases. The secondary sources of data used in the research are company reports, press releases, and government sources.

6. Data Triangulation

The data triangulation approach is adopted in the research methodology to ensure the accuracy and reliability of the data used. This includes conducting both demand-side and supply-side data triangulation. The demand-side data triangulation involves analyzing the market from the perspective of the customers such as their preferences, needs, and requirements. The supply-side data triangulation involves analyzing the market from the perspective of the suppliers such as their production capabilities, pricing strategies, and sales strategies.

7. Factor Analysis

The Factor Analysis approach is adopted in the research methodology to identify the key drivers, challenges, and opportunities in the Super Engineering Plastics Market. This is done by analyzing the impact of various factors such as technological advancement, economic environment, competitive landscape, and regulatory environment on the Super Engineering Plastics Market.

8. Time Series Analysis

The Time Series Analysis approach is adopted in the research methodology to understand the market trends over time. This is done by analyzing various market parameters such as market size, market volume, market share, revenue, and growth rate over a given time period. This helps to gain an understanding of the performance of the Super Engineering Plastics Market in terms of its growth and potential.

9. Statistical Analysis

The Statistical Analysis approach is adopted in the research methodology to analyze the key trends and patterns in the Super Engineering Plastics Market. This is achieved by analyzing the data collected from primary and secondary sources using various statistical techniques such as correlation analysis, regression analysis, cluster analysis, and factor analysis.

10. Conclusion

This research study involves extensive primary and secondary research sources to analyze the Super Engineering Plastics Market in a detailed and comprehensive manner. Various research approaches such as factor analysis, time series analysis, statistical analysis, and demand side and supply side data triangulation have been used to gain accurate and reliable data. The research methodology adopted is both descriptive and explanatory in nature and involves various assumptions and limitations.