Top Industry Leaders in the Super Engineering Plastics Market

Super Engineering Plastics Market

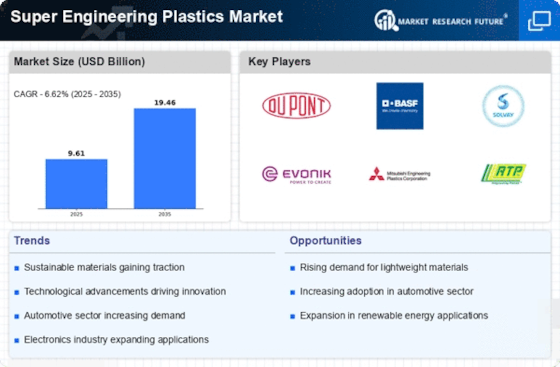

This upward trajectory is orchestrated by a powerful force: the demand for materials that can withstand extreme conditions, offering superior strength, heat resistance, and chemical resilience. But beneath this dynamic scene lies a complex battleground, where leading players vie for market share, employing distinct strategies and navigating ever-evolving trends.

Strategies Forging a Winning Tune:

-

Product Innovation: Players like Solvay, DuPont, and Evonik are constantly pushing the boundaries, developing new formulations with enhanced properties like fire retardancy, wear resistance, and biocompatibility. -

Sustainability Focus: With environmental concerns gaining traction, companies are investing in bio-based super engineering plastics or exploring recycling technologies for end-of-life products. -

Vertical Integration: Some players are pursuing vertical integration, acquiring raw material suppliers or expanding into downstream production of components for specific industries. -

Geographical Expansion: Emerging markets like China, India, and Southeast Asia offer immense potential. Companies are establishing production facilities and distribution networks in these regions to capture the surging demand. -

Partnerships and Acquisitions: Strategic partnerships and acquisitions are a common strategy to access new technologies, regional expertise, and customer bases, amplifying market reach and capabilities.

Factors Dictating Market Share:

-

Production Capacity and Technology: Companies with large production capacities and access to advanced production technologies can cater to high demand volumes and offer competitive pricing. -

Brand Reputation and Customer Relationships: Established brands with strong reputations and long-standing customer relationships often enjoy market loyalty and a larger share of the pie. -

Product Portfolio Diversity: A diverse portfolio catering to various applications like aerospace, automotive, and medical devices allows companies to attract a wider customer base. -

Cost Competitiveness: The highly competitive nature of the market necessitates efficient production processes and competitive pricing strategies to secure market share. -

Regulatory Compliance: Meeting stringent environmental and safety regulations, particularly in Europe and North America, is crucial for market access and customer trust.

Key Players:

- Solvay (Belgium)

- TORAY INDUSTRIES, INC. (Japan)

- DIC CORPORATION (Japan)

- Tosoh Corporation (Japan)

- KUREHA CORPORATION (Japan)

- NHU Materials Co. (China)

- LION IDEMITSU COMPOSITES CO., LTD (Japan)

- BASF SE (Germany)

- Huntsman International LLC. (US)

- LG Chem. (South Korea)

- Asahi Kasei Corporation (Japan)

- Chi Mei Corporation (Taiwan)

- Formosa Plastics Corporation (US)

Recent Developments:

-

September 2023: Several super engineering plastics producers announced price increases due to rising raw material costs and supply chain disruptions. -

October 2023: The American Society of Mechanical Engineers hosted its annual conference, focusing on advancements in super engineering plastics technology, sustainability initiatives, and market trends in the aerospace and automotive industries. -

November 2023: A global study highlighted the potential of functionalized super engineering plastics that can impart unique properties like self-healing or conductivity, opening up new avenues for product design and functionality. -

December 2023: The Chinese government announced plans to invest in the development of advanced super engineering plastics production technologies, aiming to strengthen domestic production and compete with global players.