Growth in Organic Farming Practices

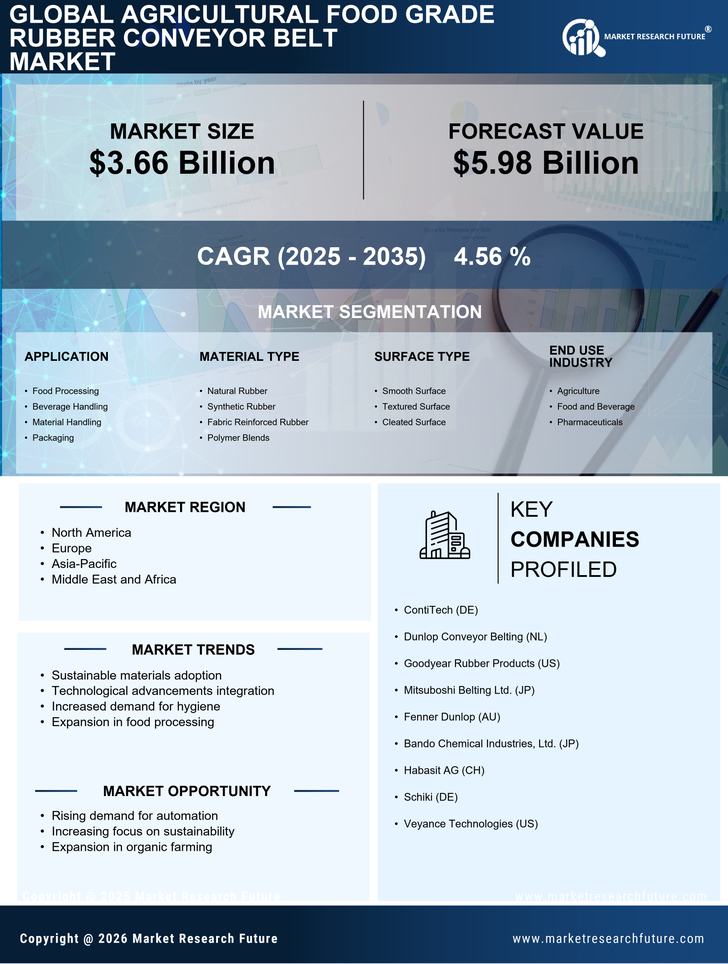

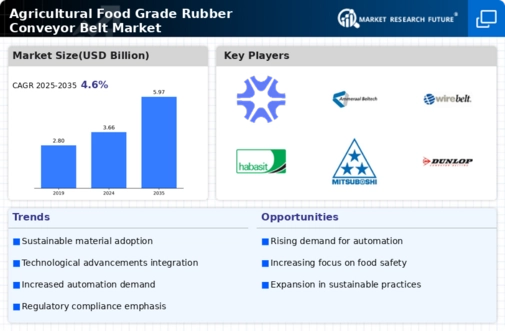

The growth in organic farming practices is emerging as a significant driver for the Agricultural Food Grade Rubber Conveyor Belt Market. As consumers become more health-conscious and environmentally aware, the demand for organic produce is surging. This shift necessitates the use of specialized equipment, including conveyor belts that are suitable for handling organic products. Market forecasts suggest that the organic food market could reach $300 billion by 2025. Consequently, the Agricultural Food Grade Rubber Conveyor Belt Market is likely to benefit from this trend, as manufacturers develop belts that cater specifically to the needs of organic farming.

Expansion of Food Processing Industries

The expansion of food processing industries is significantly influencing the Agricultural Food Grade Rubber Conveyor Belt Market. As the global population continues to grow, the demand for processed food products is on the rise. This trend necessitates efficient transportation systems within food processing facilities, where rubber conveyor belts play a crucial role. Market analysis indicates that the food processing sector is projected to grow at a rate of approximately 4% annually. This growth directly correlates with an increased need for high-quality conveyor belts that ensure food safety and hygiene, thereby driving the Agricultural Food Grade Rubber Conveyor Belt Market.

Rising Demand for Sustainable Practices

The Agricultural Food Grade Rubber Conveyor Belt Market is experiencing a notable shift towards sustainable agricultural practices. As consumers increasingly prioritize eco-friendly products, manufacturers are compelled to adopt sustainable materials and processes. This trend is reflected in the growing preference for conveyor belts made from recycled or bio-based rubber. The market for sustainable agricultural products is projected to expand, with estimates suggesting a compound annual growth rate of over 5% in the coming years. Consequently, companies that align their offerings with sustainability goals are likely to gain a competitive edge, thereby driving growth in the Agricultural Food Grade Rubber Conveyor Belt Market.

Increased Investment in Agricultural Technology

Investment in agricultural technology is a pivotal driver for the Agricultural Food Grade Rubber Conveyor Belt Market. As farmers and agribusinesses seek to enhance productivity and efficiency, they are increasingly adopting advanced technologies. This includes automated systems that utilize high-quality conveyor belts for the transportation of food products. Reports indicate that the agricultural technology sector is expected to witness investments exceeding $10 billion annually. Such financial influx not only fosters innovation but also elevates the demand for specialized conveyor belts that meet stringent food safety standards, thereby propelling the Agricultural Food Grade Rubber Conveyor Belt Market forward.

Regulatory Compliance and Food Safety Standards

Regulatory compliance and stringent food safety standards are critical drivers for the Agricultural Food Grade Rubber Conveyor Belt Market. Governments and regulatory bodies worldwide are implementing rigorous guidelines to ensure food safety, which directly impacts the materials used in food processing. Conveyor belts must adhere to these standards, leading to a heightened demand for food-grade rubber products. The market is witnessing a shift towards belts that are not only durable but also compliant with health regulations. This trend is expected to continue, as adherence to food safety standards becomes increasingly paramount, thereby bolstering the Agricultural Food Grade Rubber Conveyor Belt Market.