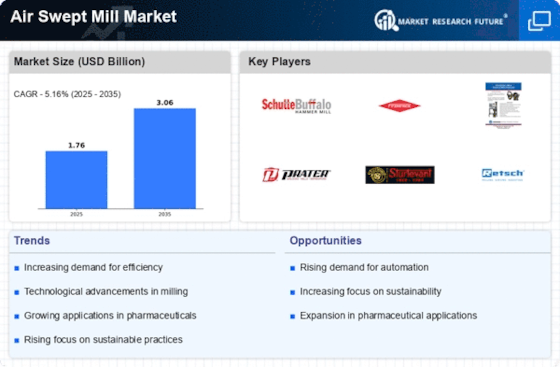

Growing Pharmaceutical Sector

The Air Swept Mill Market is significantly benefiting from the growth of the pharmaceutical sector, which requires precise milling solutions for active pharmaceutical ingredients and excipients. As the pharmaceutical industry continues to expand, driven by increasing healthcare needs and innovations in drug development, the demand for high-quality milling equipment is likely to rise. Air swept mills offer the capability to produce fine powders with consistent particle size distribution, which is crucial for drug formulation. Market projections indicate that the pharmaceutical sector is expected to grow at a rate of approximately 6.5% annually, further enhancing the prospects for air swept mills in this critical industry.

Expansion of the Chemical Industry

The Air Swept Mill Market is significantly influenced by the expansion of the chemical industry, which requires advanced milling solutions for various applications. As chemical manufacturers seek to optimize production processes and enhance product quality, the demand for efficient milling technologies, such as air swept mills, is likely to rise. The chemical sector's growth is projected to be around 4.8% annually, driven by increasing applications in agriculture, coatings, and specialty chemicals. This expansion creates a favorable environment for the Air Swept Mill Market, as it provides the necessary capabilities to meet the stringent requirements of modern chemical processing.

Increased Focus on Energy Efficiency

Energy efficiency has become a critical consideration in the Air Swept Mill Market, as manufacturers seek to reduce operational costs and minimize environmental impact. The growing emphasis on sustainable practices is prompting companies to invest in energy-efficient milling technologies. Air swept mills, known for their low energy consumption and high throughput, are well-positioned to capitalize on this trend. Market analysis suggests that energy-efficient milling solutions could lead to cost savings of up to 20% for manufacturers, making them an attractive option in an increasingly competitive landscape. This focus on energy efficiency is likely to drive further adoption of air separation plant across various industries.

Rising Demand for Fine Powder Products

The Air Swept Mill Market is experiencing a notable increase in demand for fine powder products across various sectors, including pharmaceuticals, food processing, and chemicals. This trend is driven by the need for high-quality, finely milled materials that enhance product performance and efficacy. As industries strive for improved product characteristics, the Air Swept Mill Market's ability to produce ultra-fine powders efficiently positions it as a preferred choice. Market data indicates that the demand for fine powders is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years, further solidifying the Air Swept Mill Market's role in meeting these evolving requirements.

Technological Innovations in Milling Equipment

The Air Swept Mill Market is witnessing a wave of technological innovations that enhance the performance and versatility of milling equipment. Advancements in design, materials, and control systems are enabling air swept mills to operate more efficiently and effectively. These innovations not only improve milling precision but also expand the range of materials that can be processed. As industries demand more sophisticated milling solutions, the integration of smart technologies and automation into air swept mills is expected to become a key driver of market growth. This trend indicates a shift towards more intelligent manufacturing processes, positioning air swept mills as essential tools in modern production environments.