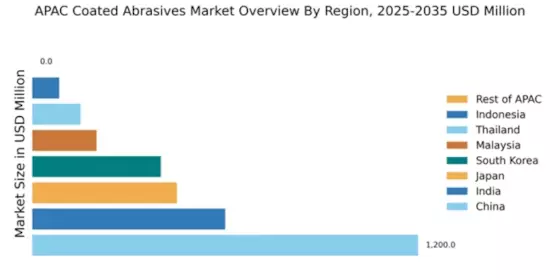

China : Unmatched Growth and Demand Trends

China holds a commanding market share of 40% in the APAC coated abrasives sector, valued at $1200.0 million. Key growth drivers include rapid industrialization, increasing automotive production, and a booming construction sector. Demand trends indicate a shift towards high-performance abrasives, driven by stringent quality standards and government initiatives promoting advanced manufacturing. Infrastructure development, particularly in urban areas, further fuels consumption patterns.

India : Robust Growth in Manufacturing Sector

India accounts for a 30% share of the APAC coated abrasives market, valued at $600.0 million. The growth is propelled by the expanding manufacturing sector, particularly in automotive and metalworking industries. Demand is rising for specialized abrasives, supported by government initiatives like 'Make in India' that encourage local production. Regulatory policies are also evolving to ensure quality and safety standards in manufacturing.

Japan : Innovation in Coated Abrasives

Japan holds a 22.5% market share in the APAC coated abrasives market, valued at $450.0 million. The growth is driven by technological advancements and a focus on high-precision applications in electronics and automotive sectors. Demand trends show a preference for eco-friendly products, influenced by stringent environmental regulations. Government initiatives are promoting R&D in advanced materials, enhancing market potential.

South Korea : Key Player in Coated Abrasives

South Korea represents a 20% share of the APAC coated abrasives market, valued at $400.0 million. The growth is supported by a robust industrial base, particularly in shipbuilding and electronics. Demand trends indicate a shift towards high-performance abrasives, driven by competitive manufacturing practices. Government policies are focused on innovation and sustainability, fostering a conducive business environment.

Malaysia : Strategic Location for Trade

Malaysia captures a 10% share of the APAC coated abrasives market, valued at $200.0 million. The growth is fueled by increasing demand from the automotive and construction sectors. The strategic location enhances trade opportunities, while government initiatives support local manufacturing. Demand trends show a rising preference for quality abrasives, influenced by regulatory standards aimed at improving product safety.

Thailand : Focus on Manufacturing and Exports

Thailand holds a 7.5% share of the APAC coated abrasives market, valued at $150.0 million. The growth is driven by investments in manufacturing and export-oriented industries. Demand trends indicate a rising need for specialized abrasives in automotive and electronics sectors. Government policies are promoting foreign investment, enhancing the competitive landscape and business environment.

Indonesia : Investment in Infrastructure Development

Indonesia accounts for a 3.5% share of the APAC coated abrasives market, valued at $84.0 million. The growth is supported by ongoing infrastructure development and a burgeoning manufacturing sector. Demand trends show an increasing preference for cost-effective solutions, influenced by local market dynamics. Government initiatives are aimed at improving industrial capabilities, fostering a favorable business environment.

Rest of APAC : Exploring New Market Opportunities

The Rest of APAC region currently holds no significant market share in coated abrasives, valued at $0.0 million. However, there is untapped potential driven by increasing industrial activities and demand for quality abrasives. Emerging markets are beginning to adopt advanced manufacturing practices, creating opportunities for growth. Regulatory frameworks are evolving to support local industries, paving the way for future market development.