Growth in Automotive Applications

The automotive industry is increasingly integrating advanced composite materials to improve vehicle performance and safety. The Aramid Prepreg Market is poised to benefit from this trend, as aramid prepregs offer superior mechanical properties and thermal stability. With the rise of electric vehicles and the need for lightweight components, the demand for aramid prepregs is expected to surge. Market analysis suggests that the automotive sector could represent a significant portion of the aramid prepreg market, potentially reaching 25% by 2026. This growth is indicative of a broader shift towards sustainable and efficient automotive solutions, further solidifying the position of the Aramid Prepreg Market in the composite materials landscape.

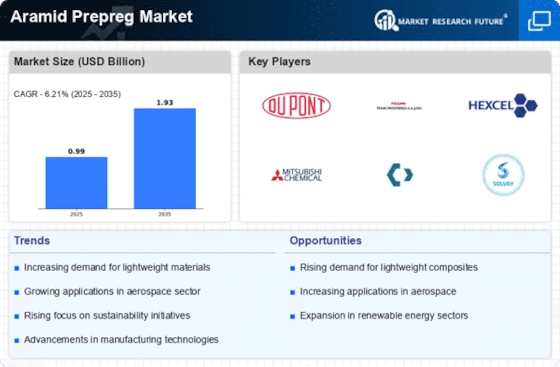

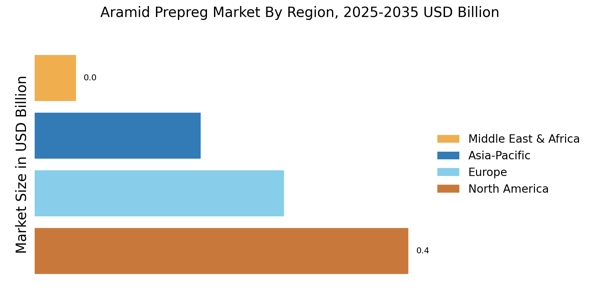

Rising Demand in Aerospace Sector

The aerospace sector is experiencing a notable increase in demand for lightweight and high-strength materials, which positions the Aramid Prepreg Market favorably. As aircraft manufacturers seek to enhance fuel efficiency and reduce emissions, the adoption of aramid prepregs is likely to rise. The lightweight nature of aramid fibers contributes to significant weight savings, which can lead to improved performance and lower operational costs. According to industry estimates, the aerospace segment is projected to account for a substantial share of the aramid prepreg market, potentially exceeding 30% by 2026. This trend indicates a robust growth trajectory for the Aramid Prepreg Market, driven by the need for advanced materials that meet stringent safety and performance standards.

Growing Awareness of Sustainability

There is a rising awareness of sustainability and environmental impact across industries, which is influencing the Aramid Prepreg Market. As companies strive to reduce their carbon footprint, the demand for eco-friendly materials is increasing. Aramid prepregs, known for their durability and recyclability, align well with these sustainability goals. The market is witnessing a shift towards sourcing materials that not only meet performance criteria but also adhere to environmental standards. This trend is expected to drive innovation in the development of sustainable aramid prepregs, potentially expanding their market share. As industries prioritize sustainable practices, the Aramid Prepreg Market is likely to see a corresponding increase in demand, reflecting a broader commitment to environmental responsibility.

Increased Investment in Defense Sector

The defense sector is witnessing heightened investment in advanced materials for military applications, which is likely to drive the Aramid Prepreg Market. Aramid prepregs are favored for their exceptional strength-to-weight ratio and ballistic resistance, making them ideal for protective gear and vehicle armor. As governments prioritize modernization and the development of advanced defense technologies, the demand for aramid prepregs is expected to grow. Recent reports indicate that defense spending is on the rise, with many countries allocating significant budgets for research and development in materials science. This trend suggests a promising outlook for the Aramid Prepreg Market, as defense contractors increasingly turn to aramid prepregs to meet stringent performance requirements.

Technological Innovations in Manufacturing

Technological advancements in the manufacturing processes of aramid prepregs are enhancing their performance and reducing production costs. Innovations such as automated fiber placement and advanced curing techniques are streamlining production, which may lead to increased adoption across various industries. The Aramid Prepreg Market stands to gain from these developments, as manufacturers can produce higher-quality products more efficiently. Furthermore, the introduction of new formulations and hybrid composites is expanding the application range of aramid prepregs, making them more appealing to end-users. As these technologies continue to evolve, the market is likely to experience accelerated growth, driven by improved product offerings and competitive pricing.