Customization Demand

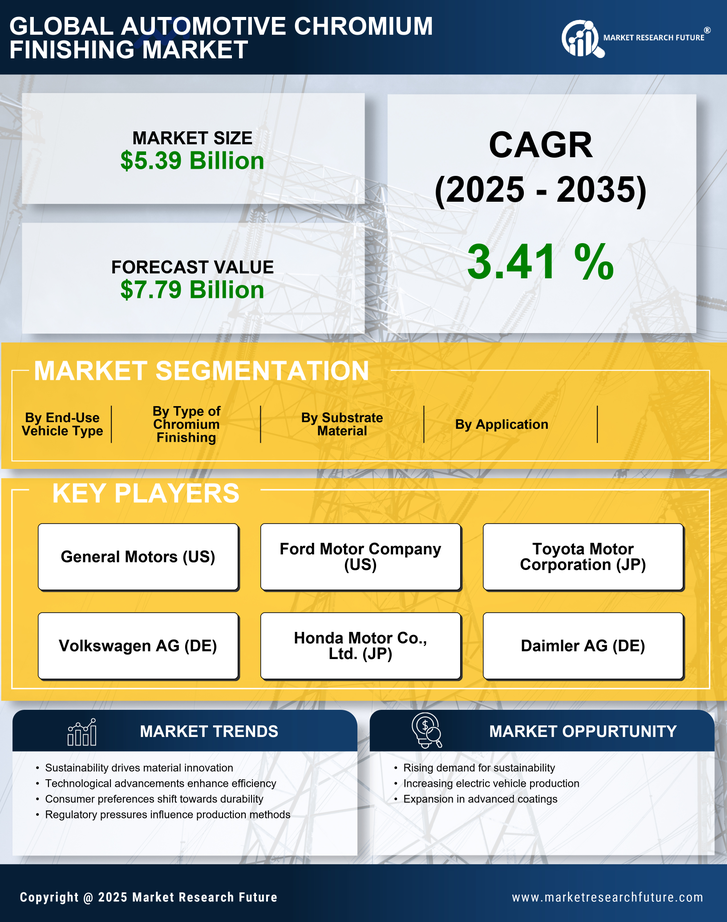

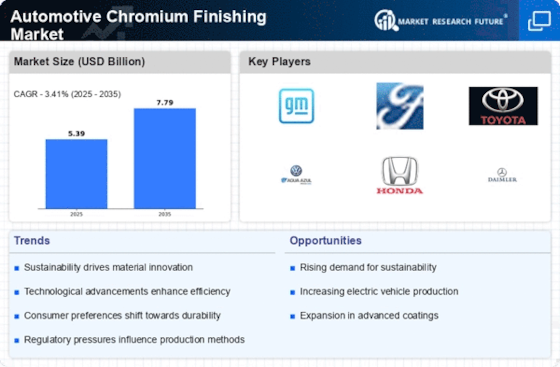

The Automotive Chromium Finishing Market is experiencing a surge in demand for customization. Consumers are increasingly seeking personalized vehicles that reflect their individual tastes and preferences. This trend has prompted manufacturers to offer a wider range of chromium finishing options, allowing for unique designs and finishes. The ability to customize not only enhances the aesthetic appeal of vehicles but also adds value, making them more attractive to potential buyers. Market data indicates that the customization segment is projected to grow at a compound annual growth rate of approximately 5% over the next five years. This growth is likely to be fueled by advancements in technology that enable more intricate and varied finishing processes. As a result, the Automotive Chromium Finishing Market is adapting to meet these evolving consumer demands, thereby fostering innovation and competition among manufacturers.

Regulatory Compliance

Regulatory compliance is a critical driver for the Automotive Chromium Finishing Market. Governments worldwide are implementing stringent regulations regarding the use of hazardous materials in manufacturing processes, particularly concerning chromium plating. These regulations aim to protect the environment and public health, compelling manufacturers to adapt their processes accordingly. Compliance with these regulations often requires investment in new technologies and practices, which can be costly but necessary for market participation. As a result, companies that proactively address these compliance issues are likely to gain a competitive edge. The Automotive Chromium Finishing Market is thus witnessing a shift towards safer, more sustainable practices, which not only fulfill regulatory requirements but also enhance brand reputation among consumers.

Sustainability Initiatives

The Automotive Chromium Finishing Market is increasingly influenced by sustainability initiatives. Manufacturers are under pressure to adopt eco-friendly practices, which has led to the development of chromium finishing processes that minimize environmental impact. This shift is evident as companies invest in technologies that reduce waste and energy consumption. For instance, the implementation of closed-loop systems in chromium plating can significantly lower hazardous waste generation. Furthermore, regulatory bodies are tightening restrictions on the use of toxic substances, prompting the industry to innovate. As a result, the market is witnessing a rise in demand for sustainable finishing solutions, which not only comply with regulations but also appeal to environmentally conscious consumers. This trend is expected to drive growth in the Automotive Chromium Finishing Market as companies strive to enhance their sustainability profiles.

Technological Advancements

Technological advancements are playing a pivotal role in shaping the Automotive Chromium Finishing Market. Innovations in plating techniques, such as the development of trivalent chromium processes, are gaining traction due to their reduced environmental impact compared to traditional hexavalent chromium methods. These advancements not only enhance the quality and durability of finishes but also align with regulatory requirements. Moreover, the integration of automation and robotics in the finishing process is streamlining operations, reducing labor costs, and improving efficiency. Market analysis suggests that the adoption of these technologies could lead to a 15% increase in production efficiency within the next few years. As manufacturers continue to invest in cutting-edge technologies, the Automotive Chromium Finishing Market is likely to witness significant growth, driven by enhanced product offerings and operational efficiencies.

Rising Automotive Production

The Automotive Chromium Finishing Market is significantly influenced by the rising production of vehicles. As global automotive production continues to expand, the demand for high-quality finishing solutions is also increasing. In recent years, production levels have shown a steady upward trend, with estimates indicating that over 90 million vehicles are produced annually. This surge in production necessitates efficient and effective finishing processes to meet quality standards and consumer expectations. Consequently, manufacturers are increasingly turning to chromium finishing as a preferred method due to its durability and aesthetic appeal. The growth in automotive production is expected to drive the Automotive Chromium Finishing Market, as companies seek to enhance their offerings and maintain competitiveness in a crowded marketplace.