Increasing Vehicle Production Rates

The Automotive Progressive Wound Spring Market is significantly influenced by the rising production rates of vehicles across various segments. As manufacturers ramp up production to meet consumer demand, the need for high-quality components, including progressive wound springs, is becoming more pronounced. Recent statistics indicate that global vehicle production is expected to reach approximately 100 million units annually by 2026, reflecting a steady growth trajectory. This surge in production not only drives demand for springs but also encourages manufacturers to enhance their supply chain efficiencies. Consequently, the Automotive Progressive Wound Spring Market is poised for growth, as suppliers strive to meet the increasing volume requirements while maintaining quality standards. This dynamic environment presents opportunities for innovation and collaboration among industry players.

Focus on Enhanced Vehicle Performance

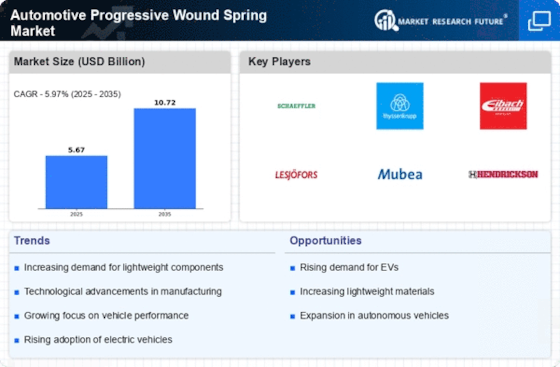

The Automotive Progressive Wound Spring Market is witnessing a heightened emphasis on enhancing vehicle performance, which is driving demand for advanced spring solutions. As consumers increasingly prioritize performance attributes such as handling, stability, and ride comfort, manufacturers are compelled to innovate their spring designs. Progressive wound springs, known for their ability to provide variable spring rates, are particularly well-suited to meet these performance demands. Market analysis suggests that the performance-oriented segment of the automotive industry is expected to grow at a rate of approximately 4% annually. This trend indicates a robust opportunity for the Automotive Progressive Wound Spring Market to develop specialized products that cater to performance enthusiasts and manufacturers alike, thereby fostering a competitive landscape.

Rising Demand for Lightweight Materials

The Automotive Progressive Wound Spring Market is experiencing a notable shift towards lightweight materials, driven by the automotive sector's increasing focus on fuel efficiency and emissions reduction. Manufacturers are increasingly adopting progressive wound springs made from advanced materials that offer superior strength-to-weight ratios. This trend aligns with the broader industry movement towards lightweight vehicle designs, which can enhance performance and reduce fuel consumption. According to recent data, the demand for lightweight components in vehicles is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. As automakers strive to meet stringent regulatory standards, the adoption of lightweight materials in the Automotive Progressive Wound Spring Market is likely to accelerate, fostering innovation and competitiveness among manufacturers.

Regulatory Compliance and Safety Standards

The Automotive Progressive Wound Spring Market is increasingly shaped by stringent regulatory compliance and safety standards imposed on vehicle manufacturers. As governments worldwide implement more rigorous safety regulations, the demand for high-quality, reliable components, including progressive wound springs, is on the rise. These springs play a crucial role in ensuring vehicle stability and safety, making them essential for compliance with safety standards. Recent data indicates that the automotive safety components market is projected to grow at a compound annual growth rate of around 5% over the next few years. Consequently, the Automotive Progressive Wound Spring Market must adapt to these evolving regulations, driving innovation and quality improvements to meet the expectations of both regulators and consumers.

Technological Innovations in Spring Manufacturing

Technological advancements are playing a pivotal role in shaping the Automotive Progressive Wound Spring Market. Innovations in manufacturing processes, such as automated production techniques and advanced material science, are enhancing the efficiency and precision of spring production. These technologies enable manufacturers to produce springs that meet the increasingly complex demands of modern vehicles, including improved durability and performance. Furthermore, the integration of computer-aided design (CAD) and simulation tools allows for the optimization of spring designs, leading to better performance characteristics. Market data indicates that the adoption of these technologies is expected to increase, with a projected growth rate of around 6% in the next few years. As a result, the Automotive Progressive Wound Spring Market is likely to witness a surge in high-quality, innovative products that cater to evolving consumer preferences.