Cost Efficiency

Cost efficiency is a critical driver in the Automotive Thermoformed Plastics Parts Packaging Market. As automotive manufacturers face increasing pressure to reduce production costs, the adoption of thermoformed plastics has emerged as a viable solution. These materials not only offer lower manufacturing costs compared to traditional packaging options but also contribute to weight reduction, which can enhance fuel efficiency in vehicles. Recent studies suggest that the use of thermoformed plastics can reduce packaging costs by approximately 15%, making them an attractive choice for manufacturers. Furthermore, the longevity and durability of thermoformed plastics reduce the need for frequent replacements, further driving down overall costs. Thus, cost efficiency remains a significant factor influencing the Automotive Thermoformed Plastics Parts Packaging Market.

Regulatory Compliance

Regulatory compliance is an essential driver in the Automotive Thermoformed Plastics Parts Packaging Market. As governments worldwide implement stricter regulations regarding packaging materials and waste management, manufacturers must adapt to these changes to remain competitive. Compliance with regulations related to recyclability and material safety is becoming increasingly important, as non-compliance can lead to substantial fines and reputational damage. The automotive sector is particularly affected, as it is subject to stringent environmental standards. Consequently, companies that proactively align their packaging strategies with regulatory requirements are likely to enhance their market position. This trend indicates that regulatory compliance will continue to shape the Automotive Thermoformed Plastics Parts Packaging Market in the foreseeable future.

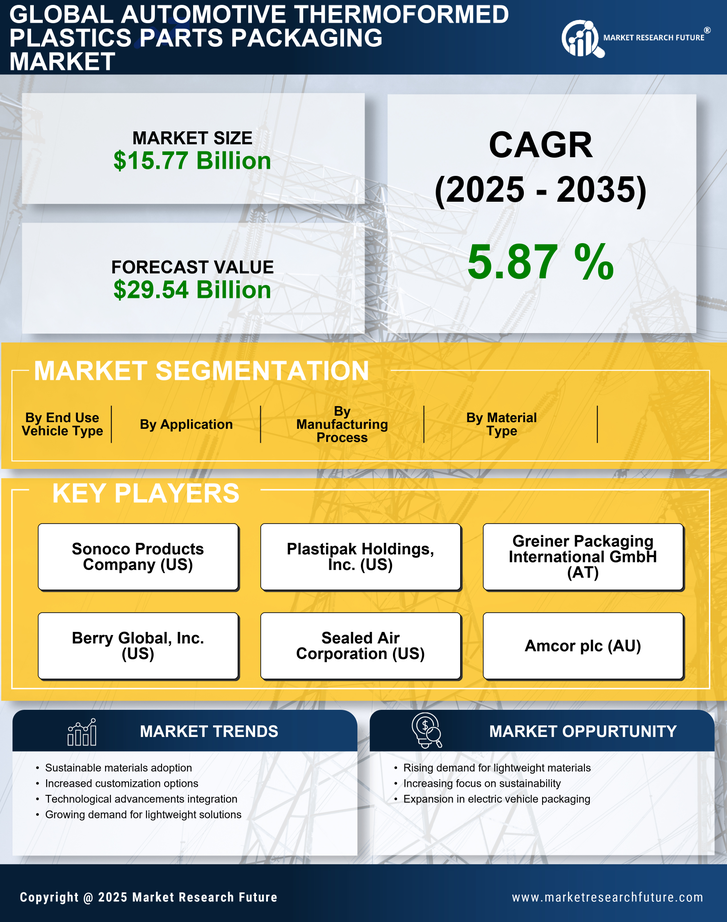

Sustainability Initiatives

The Automotive Thermoformed Plastics Parts Packaging Market is increasingly influenced by sustainability initiatives. Manufacturers are under pressure to adopt eco-friendly materials and processes, as consumers and regulatory bodies demand reduced environmental impact. The shift towards recyclable and biodegradable plastics is notable, with many companies investing in research to develop sustainable alternatives. This trend is reflected in the growing market for recycled plastics, which is projected to reach significant volumes in the coming years. Furthermore, the automotive sector is actively seeking to minimize waste through efficient packaging solutions, which enhances the appeal of thermoformed plastics. As a result, companies that prioritize sustainability are likely to gain a competitive edge in the Automotive Thermoformed Plastics Parts Packaging Market.

Technological Advancements

Technological advancements play a pivotal role in shaping the Automotive Thermoformed Plastics Parts Packaging Market. Innovations in manufacturing processes, such as improved thermoforming techniques and automation, have led to enhanced efficiency and reduced production costs. The integration of advanced materials, including high-performance plastics, is also noteworthy, as these materials offer superior durability and lightweight properties. According to recent data, the adoption of automation in packaging processes has increased productivity by up to 30%, which is crucial for meeting the demands of the automotive sector. As technology continues to evolve, it is expected that the Automotive Thermoformed Plastics Parts Packaging Market will witness further enhancements, driving growth and efficiency.

Customization and Flexibility

Customization and flexibility are becoming increasingly vital in the Automotive Thermoformed Plastics Parts Packaging Market. As automotive manufacturers strive to differentiate their products, the demand for tailored packaging solutions is on the rise. Thermoformed plastics offer the versatility needed to create unique designs that cater to specific automotive components, enhancing both functionality and aesthetics. This trend is supported by market data indicating that customized packaging solutions can lead to a 20% increase in customer satisfaction. Additionally, the ability to adapt packaging to various product lines allows manufacturers to respond swiftly to market changes, thereby improving their competitive positioning. Consequently, customization is likely to remain a key driver in the Automotive Thermoformed Plastics Parts Packaging Market.