Market Share

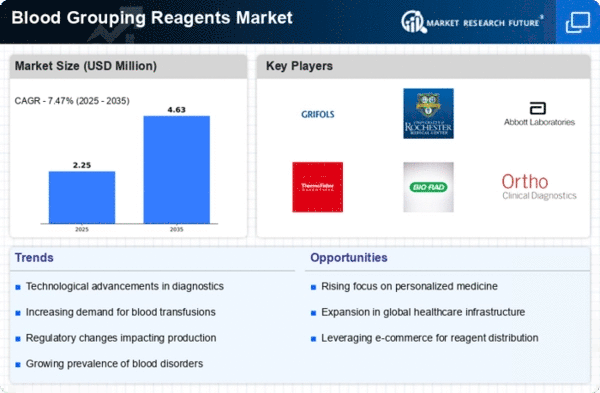

Blood Grouping Reagents Market Share Analysis

Blood grouping reagents encompass a range of crucial tests, including blood group assessments, phenotype evaluations, antibody screening, antigen typing, direct combos, and antibody identification. Crafting these products involves extensive research and rigorous clinical trials, aiming for efficiency and precision. The research and development (R&D) phase focuses on innovating new devices integrated with cutting-edge technology while enhancing existing equipment and kits. The ultimate goal is twofold: boosting efficiency and ensuring cost-effectiveness. In a market brimming with diverse products, companies strive to infuse innovative features into their pipelines, driving technological advancements. R&D is an intricate process demanding substantial expertise and skills. It commences with conceptualization, followed by meticulous product design, subsequent development, and culminating in rigorous product testing. Throughout this journey, the R&D team diligently refines new technologies to ensure precision and accuracy in test results. However, this journey is not solitary; it operates within the framework of stringent requirements set by regulatory bodies such as the US FDA and other regional regulatory authorities, ensuring that devices and drugs meet the mandated standards.

This intricate process underscores the intricacies involved in the creation of blood grouping reagents, highlighting the industry's commitment to delivering accurate, reliable, and efficient products. From conceptualization through rigorous testing, each step demands precision and adherence to stringent regulatory standards. The amalgamation of technological innovation and adherence to regulatory benchmarks forms the bedrock of producing reliable blood grouping reagents indispensable to healthcare diagnostics and treatment.

Once product strategies are finalized, the manufacturing phase kicks off, marking the inception of product realization. This manufacturing journey initiates with the gathering and assembly of raw materials, orchestrating the production of devices, kits, and related products either in-house or through collaborations with third-party manufacturers. Raw material procurement stands as an initial and pivotal phase within the manufacturing process, particularly crucial in crafting consumables and instruments integral to blood grouping reagents. Additionally, seeking cost-effective alternatives for pricey raw materials becomes imperative to streamline the manufacturing costs. Manufacturing operations are characterized by swiftness, swiftly transitioning to testing phases. Consequently, market players prioritize initiatives aimed at reducing production costs, underscoring the industry's concerted efforts to optimize expenses without compromising on quality or efficiency.

Leave a Comment