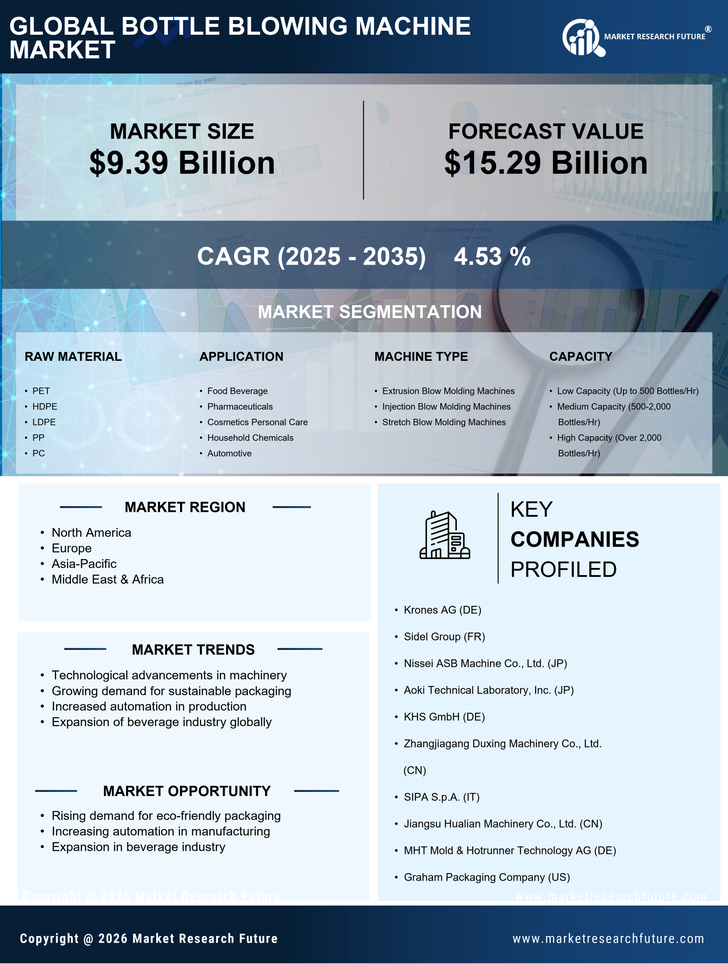

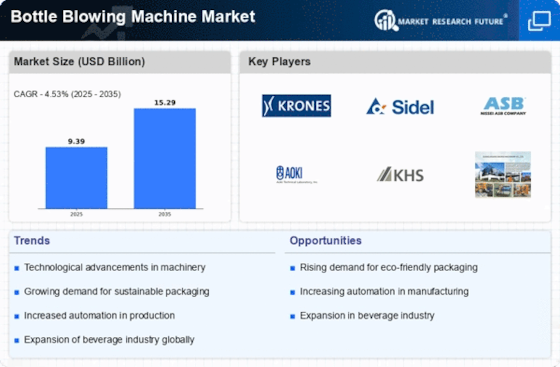

Rising Demand for Bottled Beverages

The Bottle Blowing Machine Market is significantly influenced by the rising demand for bottled beverages. As consumer preferences shift towards convenience and portability, the beverage industry is expanding rapidly. Reports indicate that the bottled water segment alone is expected to witness a growth rate of approximately 7% annually. This surge in demand necessitates efficient production capabilities, prompting manufacturers to invest in advanced bottle blowing machines. The ability to produce a variety of bottle shapes and sizes quickly and efficiently is crucial for companies aiming to capitalize on this trend, thereby driving the market forward.

Expansion of E-commerce and Retail Channels

The expansion of e-commerce and retail channels is reshaping the Bottle Blowing Machine Market. As online shopping becomes increasingly prevalent, the demand for packaging solutions that cater to direct-to-consumer sales is on the rise. This trend necessitates the production of lightweight, durable bottles that can withstand shipping and handling. Data indicates that e-commerce sales in the beverage sector are projected to grow by over 10% annually, creating a pressing need for manufacturers to enhance their production capabilities. Consequently, bottle blowing machine manufacturers are likely to see increased orders as companies seek to optimize their packaging solutions for the online marketplace.

Regulatory Compliance and Quality Standards

Regulatory compliance and quality standards are critical drivers within the Bottle Blowing Machine Market. As governments implement stricter regulations regarding food and beverage packaging, manufacturers must ensure that their products meet these standards. This includes adhering to safety and quality guidelines that govern the materials used in bottle production. Data shows that non-compliance can lead to significant financial penalties and loss of market access. Therefore, manufacturers are increasingly investing in advanced bottle blowing technologies that not only comply with regulations but also enhance product quality, thereby fostering consumer trust and brand loyalty.

Sustainability Initiatives Driving Market Growth

Sustainability initiatives are becoming increasingly pivotal within the Bottle Blowing Machine Market. As environmental concerns gain prominence, manufacturers are compelled to adopt eco-friendly practices. This includes the production of bottles using recycled materials and the implementation of energy-efficient machines. Data suggests that the market for sustainable packaging is projected to grow significantly, with a compound annual growth rate of over 5% in the coming years. Consequently, companies that invest in sustainable bottle blowing technologies are likely to gain a competitive edge, appealing to environmentally conscious consumers and meeting regulatory requirements.

Technological Advancements in Bottle Blowing Machines

The Bottle Blowing Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as improved automation, enhanced energy efficiency, and the integration of IoT technologies are reshaping production processes. For instance, the introduction of servo-driven systems has led to increased precision and reduced cycle times, which can enhance overall productivity. According to recent data, the adoption of advanced machinery has the potential to increase output by up to 30%, thereby meeting the rising demand for high-quality plastic bottles. Furthermore, these advancements not only streamline operations but also contribute to cost savings, making manufacturers more competitive in the market.